The Importance of Buying a Pipe Grinding Machine

In today’s manufacturing landscape, precision and quality have become paramount in nearly every industry, especially when it comes to metalworking and fabrication. One essential piece of equipment that has taken center stage is the pipe grinding machine. Often overlooked, this machine can drastically improve the efficiency and quality of pipe work. In this article, we'll delve into why investing in a pipe grinding machine is a smart move for any business engaged in pipe fabrication or finishing.

Understanding Pipe Grinding Machines

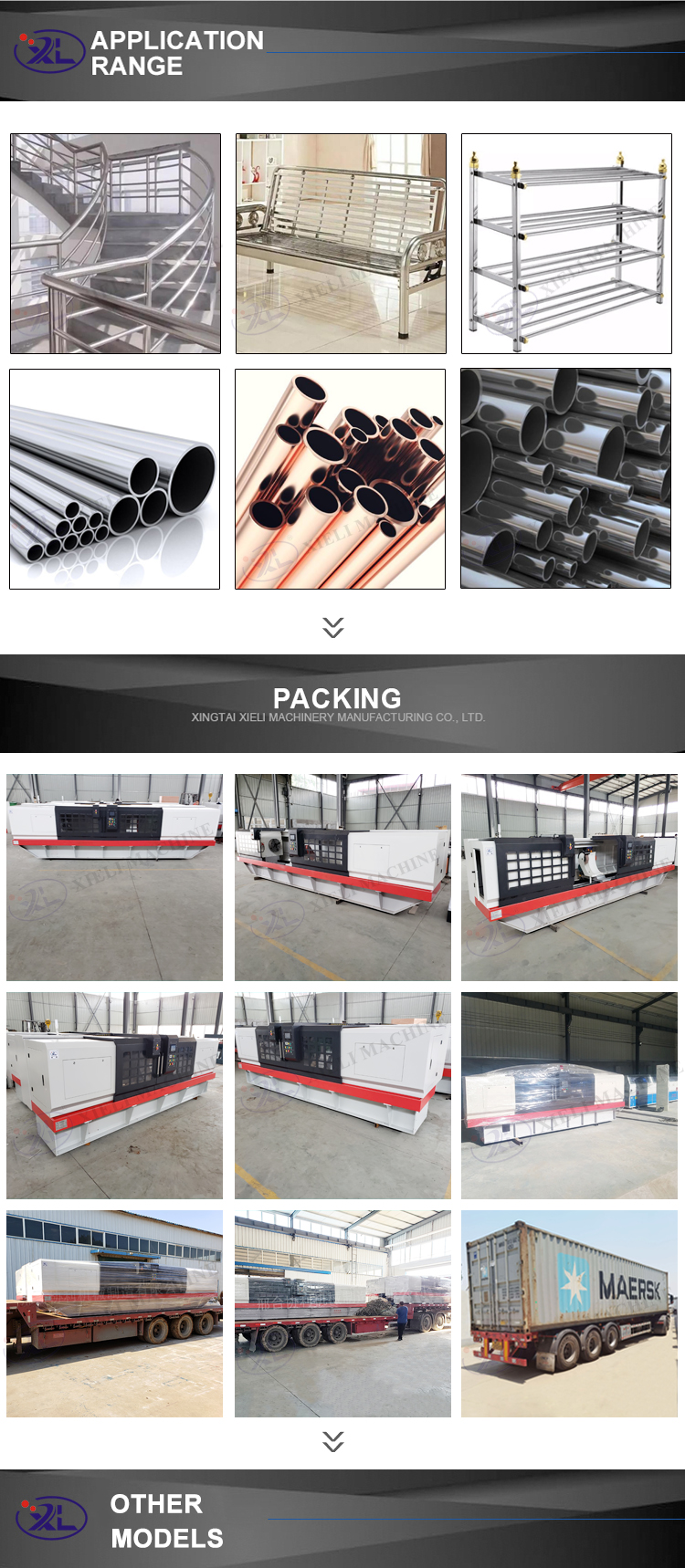

A pipe grinding machine is a specialized tool designed for grinding and finishing pipes and tubes made from various materials, including metal and plastic. These machines are engineered to create smooth finishes, remove imperfections, and prepare surfaces for further processing, such as welding or coating. The versatility of these machines allows them to handle different pipe sizes and materials, making them indispensable in manufacturing and construction environments.

The Benefits of Buying a Pipe Grinding Machine

1. Enhanced Quality of Work One of the foremost advantages of using a pipe grinding machine is the quality of the final product. Pipes that undergo grinding possess a uniform and smooth surface, which is crucial for applications requiring a tight seal and structural integrity. A well-finished pipe can also improve aesthetics, especially in visible parts of construction projects.

2. Increased Efficiency The automation and precision provided by modern pipe grinding machines can significantly speed up the production process. Compared to manual grinding, which can be labor-intensive and time-consuming, these machines provide consistent results with less operator fatigue. This increase in efficiency can lead to higher output and reduced labor costs, making the investment worthwhile.

3. Cost-Effectiveness While the initial investment in a pipe grinding machine may seem significant, the potential return on investment can be substantial. With enhanced efficiency, reduced material waste, and decreased labor costs, businesses are likely to see a quick payback period. Additionally, the durability and longevity of high-quality machines mean they will serve their purpose for many years without requiring frequent replacements.

buy pipe grinding machine

4. Versatility Contemporary pipe grinding machines come with various attachments and features that allow for a range of functions beyond grinding, including polishing and de-burring. This versatility means that companies can handle multiple tasks with a single machine, reducing the need for several different tools and thus saving valuable space and investment in machinery.

5. Worker Safety Safety is always a priority in any industrial setting. Pipe grinding machines are often designed with safety features that protect operators from accidents associated with manual grinding. Ergonomic designs, safety guards, and automated functions help reduce the likelihood of injuries, which can result in fewer worker compensation claims and increased workplace morale.

Factors to Consider When Buying a Pipe Grinding Machine

Before making a purchase, it is critical to assess the specific needs of your operation. Consider the following factors

- Material Type Ensure the machine you choose is compatible with the materials you intend to grind. - Pipe Size Compatibility Different machines support different pipe sizes. Verify that the machine can accommodate the dimensions you typically work with. - Production Volume If your business has high production demands, investing in a more robust and automatic model may be beneficial. - Budget Establish a budget beforehand and explore options that offer the best balance between cost and capabilities.

Conclusion

In conclusion, the decision to buy a pipe grinding machine can profoundly impact the quality, efficiency, and safety of pipe fabrication operations. With multiple benefits ranging from improved product quality to worker safety, investing in a pipe grinding machine is a strategic choice that pays off in the long run. As industries continue to evolve, integrating advanced machinery into operations will be crucial for remaining competitive in the market. If you are in the business of pipe work, now is the time to consider enhancing your operations with a reliable pipe grinding machine.