Buying a Pipe Belt Grinding Machine What You Need to Know

In the world of metalworking and fabrication, having the right tools is essential for achieving high-quality results. One tool that stands out for its versatility and efficiency is the pipe belt grinding machine. This specialized equipment is designed to grind, polish, and finish pipes and tubes of various shapes and sizes, making it an indispensable addition to workshops that work with metal. If you're considering buying a pipe belt grinding machine, here’s what you should know.

Understanding Pipe Belt Grinding Machines

A pipe belt grinding machine utilizes a continuous loop of abrasive material to grind and finish the surface of metal pipes. These machines can accommodate various pipe diameters and profiles, from small tubes to larger industrial pipes. They are commonly used in industries such as manufacturing, automotive, construction, and metal fabrication.

The key features of a pipe belt grinding machine typically include adjustable speed controls, a variety of belt sizes, and attachments for different finishing applications. Some models may offer additional features like dust collection systems, which help maintain a cleaner working environment, and adjustable work tables for added versatility.

Factors to Consider Before Purchase

When buying a pipe belt grinding machine, several factors should influence your decision

1. Type of Materials You Work With Consider the types of materials you’ll be grinding. Some machines are better suited for stainless steel, while others might excel with carbon steel or aluminum. Ensure that the machine you choose is compatible with your material requirements.

2. Pipe Size and Shape Different machines have varying capacities for the size and shape of pipes they can handle. Assess the range of pipe dimensions you plan to work with and choose a machine that accommodates those specifications.

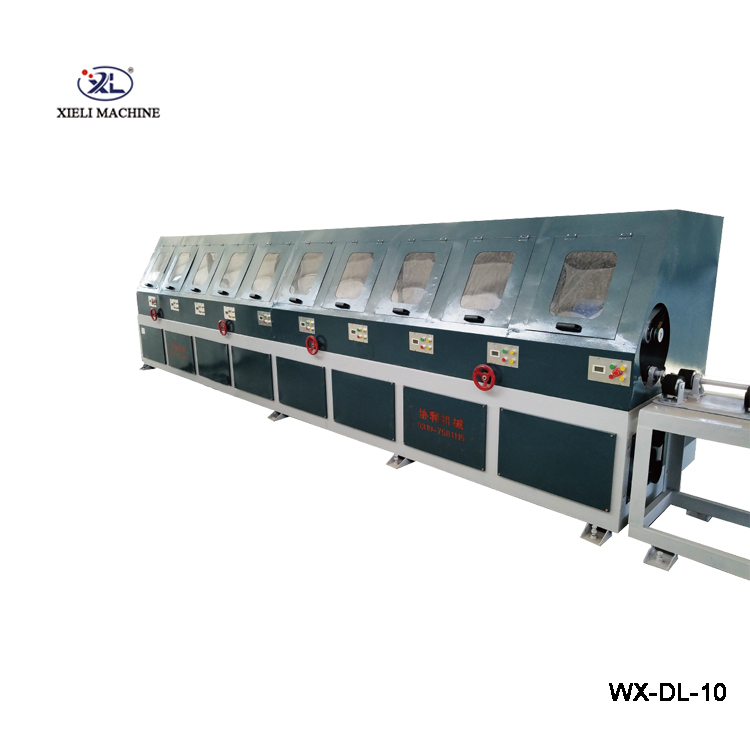

buy pipe belt grinding machine

3. Power and Speed Control Variable speed settings are crucial for achieving the desired finish on different materials. Machines with adjustable power will allow you to work more efficiently on various projects without damaging the material.

4. Brand Reputation and Reliability Investing in a machine from a reputable brand can often lead to better performance and support. Look for reviews and testimonials from other users to gauge reliability.

5. Budget and Value Pipe belt grinding machines come in a wide price range. Determine your budget but also consider the long-term value of the machine. Sometimes, spending a bit more upfront can save money in repairs and replacements down the line.

6. Maintenance and Support Consider the ease of maintenance and the availability of support and spare parts. A machine that is easy to maintain will save time and effort, and having good customer support can be vital for troubleshooting any issues that arise.

Additional Features to Look For

In addition to the basic features, some machines come with extra functionalities that enhance their usability. For instance, machines with integrated cooling systems can prevent overheating during prolonged use. Also, machines equipped with additional attachments, such as flap discs or polishing wheels, can provide more versatility for diverse finishing applications.

Conclusion

Buying a pipe belt grinding machine is an investment that can significantly enhance your metalworking operations. By carefully considering the factors outlined above—material compatibility, size handling, power settings, budget, and brand reliability—you can find the machine that best suits your needs. Remember that the right machine will not only improve efficiency and productivity but also the quality of your finished products. Take your time in the selection process, and you’ll soon see the benefits of adding a high-quality pipe belt grinding machine to your workshop.