Understanding Customized Centerless Grinders A Smart Investment for Precision Manufacturing

In today’s fast-paced manufacturing environment, precision and efficiency are paramount. As industries evolve, so do the tools and machinery that support them. One such pivotal tool is the centerless grinder, particularly customized versions that cater to specific manufacturing needs. This article explores the advantages of investing in customized centerless grinders and how they can significantly enhance productivity and quality in various applications.

What is a Centerless Grinder?

A centerless grinder is a type of grinding machine that utilizes a unique mechanism to grind workpieces without the need for a center point. Instead, the workpiece is held between two wheels a grinding wheel and a regulating wheel. This system allows for continuous feeding of workpieces, offering a streamlined and efficient grinding process. Centerless grinders are widely used for producing high-precision components such as shafts, pins, and tubing.

The Case for Customization

While standard centerless grinders are effective for general applications, they may not meet the specific requirements of every manufacturing process. Customized centerless grinders are designed to accommodate unique specifications, materials, and production volumes. This level of customization can greatly enhance operational efficiency and precision, making it a worthwhile investment for businesses aiming to maintain a competitive edge.

Benefits of Customized Centerless Grinders

1. Increased Precision and Tolerance Customized grinders can be engineered to meet stringent quality requirements. By tailoring the machine to a specific process, manufacturers can achieve tighter tolerances, reducing the likelihood of defects and ensuring consistency in production.

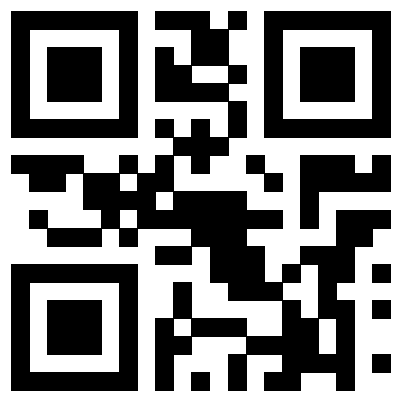

buy customized centerless grinder

2. Enhanced Efficiency A machine designed to fit specific operational needs can streamline production processes. Customized features may include specialized feed systems, tailor-made wheels, and enhanced automation capabilities that contribute to faster cycle times and reduced downtime.

3. Adaptability to Various Materials Different materials require different grinding approaches. Customized grinders can be adjusted to effectively handle a wide range of materials, from metals to plastics, ensuring optimal performance for diverse applications.

4. Improved Safety and Ergonomics Customization isn’t just about performance; it’s also about creating a safer workplace. Engineers can incorporate safety features and ergonomic designs that facilitate ease of use, thereby reducing the risk of accidents and enhancing operator comfort.

5. Long-term Cost Efficiency While customized machines may require a larger upfront investment, they often lead to long-term savings by reducing waste, minimizing downtime, and increasing the lifespan of the machine. The ability to produce high-quality parts consistently also means reduced rework and scrap costs.

6. Support for Specialized Applications Certain industries, such as aerospace, medical, or automotive, demand specialized grinding solutions. Customized centerless grinders can be designed to meet the unique requirements of these sectors, ensuring compliance with strict industry standards.

Conclusion

In conclusion, purchasing a customized centerless grinder represents a strategic investment for manufacturers looking to enhance their production capabilities. The precision, efficiency, and adaptability offered by these machines make them suitable for a broad spectrum of applications. As industries continue to expand and evolve, the ability to tailor machinery to specific needs will become increasingly essential. Embracing customization not only improves operational efficiency but also positions businesses for future growth in an ever-competitive marketplace. Investing in a customized centerless grinder could well be the key to unlocking new levels of productivity and success in manufacturing.