A Comprehensive Guide to Buying CNC Centerless Grinder Machines

In today's manufacturing landscape, precision and efficiency are paramount. One machine that epitomizes these qualities is the CNC centerless grinder. As industries continue to evolve, the demand for high-quality, precise grinding solutions has surged. This article delves into the features, benefits, and considerations of purchasing a CNC centerless grinder machine, helping manufacturers make informed decisions.

Understanding CNC Centerless Grinders

A CNC centerless grinder is a type of grinding machine that uses two rotary grinding wheels to remove material from the surface of a workpiece. Unlike conventional grinders, a centerless grinder does not require fixtures or clamping mechanisms, allowing for continuous grinding operations. This machine is particularly advantageous for high-volume production of cylindrical parts, including shafts, pins, and rods.

Key Features of CNC Centerless Grinders

1. Precision Engineering These machines offer exceptional accuracy, capable of producing tight tolerances. The CNC control systems allow for programmable adjustments, ensuring consistent results across batches.

2. Versatility CNC centerless grinders can accommodate various materials, including metals and plastics. They are suitable for a range of applications, from automotive to aerospace manufacturing.

3. Automation The integration of CNC technology allows for automation in the grinding process, reducing the need for manual intervention and minimizing human error.

4. Increased Productivity With faster cycle times and the ability to grind multiple parts simultaneously, CNC centerless grinders enhance productivity, ultimately leading to lower operational costs.

5. User-Friendly Interfaces Modern machines come equipped with intuitive control panels that simplify programming and operation, making them accessible to skilled operators without extensive training.

Benefits of Using CNC Centerless Grinders

Investing in a CNC centerless grinder machine offers numerous advantages

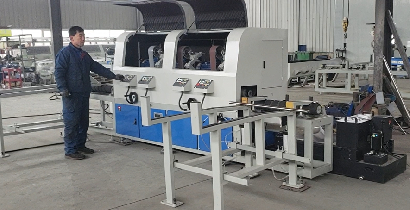

buy cnc centerless grinder machine

2. Quality and Consistency The precision offered by CNC technology ensures that products meet stringent quality standards, enhancing brand reputation and customer satisfaction.

3. Reduced Waste The ability to remove material effectively minimizes scrap and rework, contributing to a more sustainable manufacturing process.

4. Space-Saving Design CNC centerless grinders typically have a compact footprint, making them ideal for facilities with limited space.

Considerations When Buying a CNC Centerless Grinder

1. Machine Size and Specifications Before purchasing, assess the size of the workpieces you’ll be grinding. Ensure the machine you choose can accommodate the necessary dimensions and weights.

2. Control Systems Look for machines equipped with advanced CNC control systems that allow for easy programming and integration with other manufacturing processes.

3. Manufacturer Reputation Research and select reputable manufacturers known for producing reliable CNC centerless grinders. Reviews and testimonials from other users can provide insight into the machine's performance and longevity.

4. After-Sales Support Reliable after-sales service and technical support are crucial. Ensure that the manufacturer offers adequate training and assistance for machine maintenance and troubleshooting.

5. Budget Considerations While it’s essential to find a machine that fits your budget, consider the long-term value. Cheaper machines may not offer the same level of performance or longevity, resulting in higher costs over time.

6. Customization Options Some manufacturers offer customizable features based on specific grinding requirements. Consider whether such customizations are necessary for your production processes.

Conclusion

The investment in a CNC centerless grinder machine can significantly enhance manufacturing capabilities, productivity, and quality control. By carefully considering the features, benefits, and essential factors outlined in this guide, manufacturers can make well-informed purchasing decisions that align with their operational goals. As industries continue to grow and advance, adopting cutting-edge technology like CNC centerless grinders will be crucial for maintaining a competitive edge.