Enhancing Precision with CNC Centerless Grinders A Buyer's Guide

In the realm of modern manufacturing, precision plays a pivotal role in ensuring product quality and efficiency. Among the various tools that contribute to this precision, CNC (Computer Numerical Control) centerless grinders stand out as invaluable assets. These machines are specially designed to grind cylindrical parts to exact specifications without the need for a center hole, making them essential in industries such as automotive, aerospace, and medical devices. If you’re considering investing in a CNC centerless grinder, understanding its benefits and features can greatly influence your decision.

What is a CNC Centerless Grinder?

A CNC centerless grinder is a versatile machine that allows for the efficient and precise grinding of cylindrical workpieces. Unlike traditional grinding machines that require the workpiece to be centered, centerless grinders hold and grind the workpiece using two wheels—a grinding wheel and a regulating wheel. This design facilitates the processing of multiple parts in a continuous feed, making it ideal for high-volume production.

Key Advantages of CNC Centerless Grinders

1. Increased Production Efficiency One of the primary benefits of CNC centerless grinders is their ability to work on multiple parts simultaneously. With the capability for high-speed operation and automated loading processes, manufacturers can significantly boost productivity and reduce labor costs.

2. Enhanced Precision and Consistency CNC technology allows for exact control over the grinding process. This means that parts can be produced with a high level of accuracy and repeatability, ensuring that every piece meets stringent quality standards.

3. Space Savings Centerless grinding machines typically occupy less floor space compared to traditional cylindrical grinders, making them favorable for manufacturers aiming to optimize their production facilities.

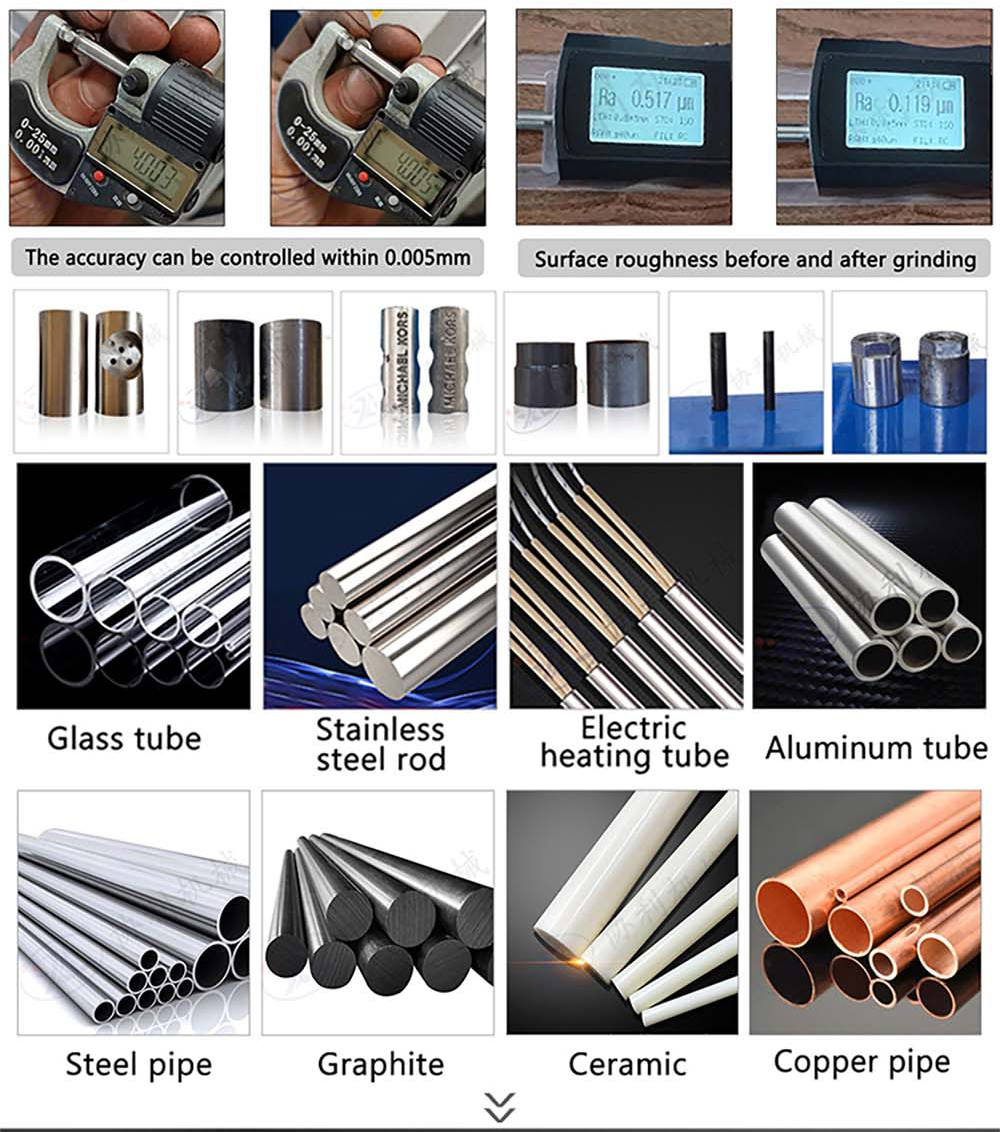

4. Versatility CNC centerless grinders can handle a wide range of materials, including metals, plastics, and composites. This versatility is beneficial for manufacturers working with diverse components or in multiple industries.

buy cnc centerless grinder

Choosing the Right CNC Centerless Grinder

When selecting a CNC centerless grinder, there are several factors to consider

1. Machine Size and Capacity Assess the sizes and types of parts you intend to grind. Ensure that the machine you choose can accommodate your largest and most complex parts.

2. Grinding Wheel Specifications Different materials and applications require specific grinding wheels. Consider options for wheel types, sizes, and the machine’s ability to handle custom wheel designs.

3. Control Systems The sophistication of the CNC control system can impact usability and programming. Look for intuitive interfaces, ease of integration with other systems, and advanced features like real-time monitoring.

4. Maintenance and Support Research the manufacturer’s reputation for service and support. A reliable partner can provide essential guidance on maintenance and troubleshooting, ensuring your investment remains operational over the long term.

5. Budget Considerations While CNC centerless grinders can represent a significant investment, it’s important to weigh upfront costs against potential operational savings in efficiency and quality. Compare different models and brands to find the best fit for your financial plan.

Conclusion

Investing in a CNC centerless grinder can be a game-changer for manufacturing operations seeking to enhance precision, efficiency, and versatility. With the capability to produce high-quality cylindrical parts with minimal setup time, these machines are indeed pivotal in pushing the boundaries of productivity. As you embark on the journey of purchasing a CNC centerless grinder, keep in mind the critical factors that will best meet your operational needs and drive your business towards greater success.