Understanding the Benefits of Buying a Centerless OD Grinder

When it comes to precision machining, the equipment you choose plays a critical role in ensuring optimal performance and high-quality outputs. One essential piece of machinery that stands out in this domain is the centerless OD (outside diameter) grinder. If you are considering the purchase of a centerless OD grinder, understanding its features, benefits, and the quotation process is crucial for making an informed decision.

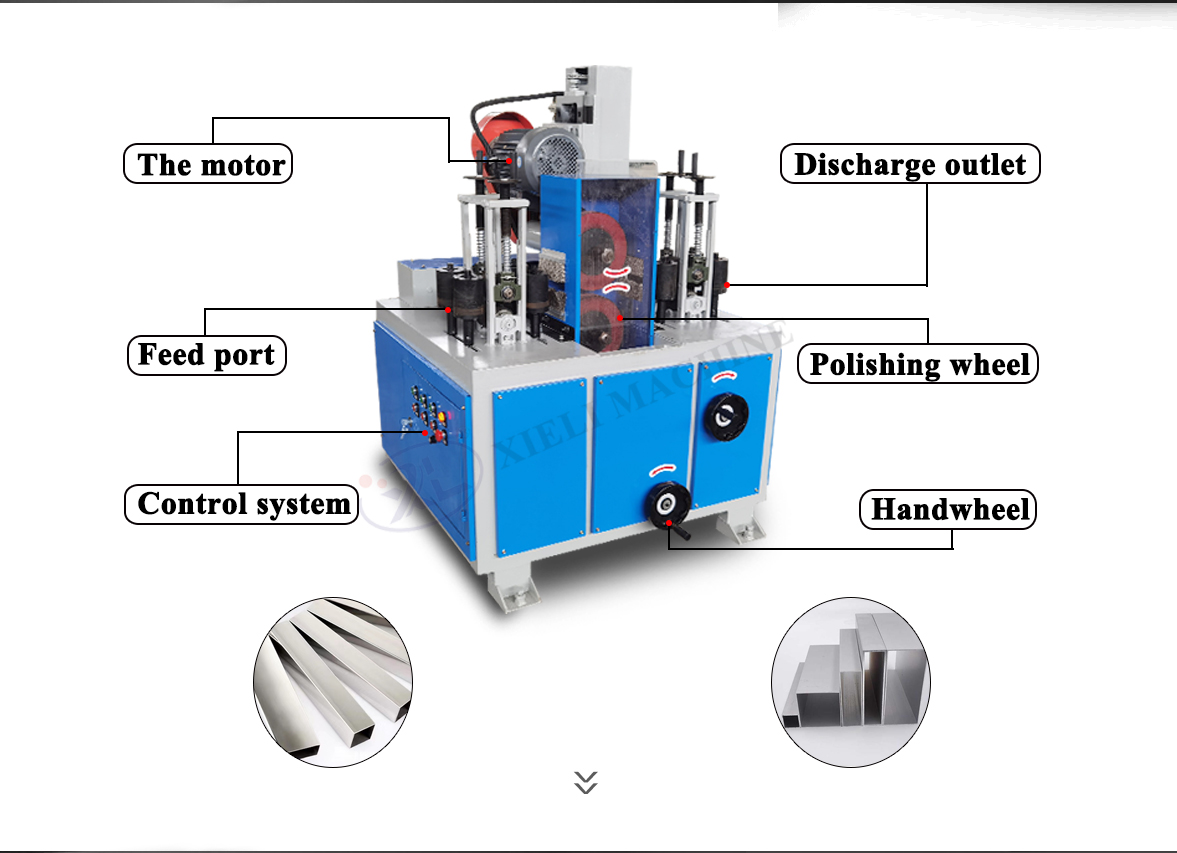

What is a Centerless OD Grinder?

A centerless OD grinder is a specialized machine designed for grinding the outer diameter of cylindrical parts. Unlike traditional grinders, which require the workpiece to be held between centers, a centerless grinder supports the workpiece through other means, allowing for continuous grinding without the need for extensive operator intervention. This setup enables more efficient production, as parts can be processed in a more streamlined manner.

Benefits of a Centerless OD Grinder

1. Enhanced Efficiency Centerless OD grinders significantly reduce cycle times. The workpiece is fed continuously through the grinding wheels, which allows for higher throughput compared to other grinding methods. This efficiency is particularly advantageous in high-volume production environments.

2. Precision Grinding These machines offer remarkable precision, capable of achieving tight tolerances that are crucial in industries such as automotive, aerospace, and medical device manufacturing. The ability to grind components with minimal operator interference ensures consistent quality across batches.

3. Versatility Centerless grinders can handle a wide range of materials and shapes, making them suitable for various applications. They are capable of grinding not just round parts but also irregularly shaped components, broadening their applicability in manufacturing.

4. Reduced Setup Time Setting up a traditional grinding machine can be time-consuming due to the need to align the workpiece properly. In contrast, centerless grinders minimize setup time, allowing quicker transitions between different projects.

buy centerless od grinder quotation

5. Cost-Effective While the initial investment in a centerless OD grinder might be significant, the long-term savings in labor, time, and material costs make it a wise choice for many businesses. Automated features can further reduce operational costs over time.

Getting a Quotation for a Centerless OD Grinder

When looking to purchase a centerless OD grinder, obtaining a detailed quotation is critical. A good quotation should include various components

- Equipment Specifications A detailed breakdown of the grinder's features, including maximum workpiece diameter, grinding wheel specifications, and available automation options.

- Pricing Clear pricing for the machine itself, including any optional features or customizations that may enhance its capabilities. Ensure that additional costs for installation, training, and warranty services are also included.

- Delivery and Lead Times Understanding the timeline for machine delivery is essential for planning your production schedule. A reputable supplier will provide realistic lead times based on their production capabilities.

- Support and Service Inquire about after-sales support, including maintenance services and training for your operators. This can greatly affect the longevity and efficiency of your new equipment.

Conclusion

Investing in a centerless OD grinder can greatly enhance the productivity and precision of your manufacturing operations. By understanding its benefits and carefully evaluating quotations, you can ensure that your investment aligns with your operational needs. As technology continues to evolve, having the right machinery, such as a centerless OD grinder, will keep your business competitive and efficient in an ever-changing marketplace.