The Rise of Homemade Centerless Grinders A Look at Innovative Factories

In recent years, the manufacturing landscape has witnessed significant changes driven by technological advancements and a growing DIY culture. One of the fascinating developments in this realm is the rise of homemade centerless grinders. These machines, essential for precision machining, allow users to grind materials with minimal effort and optimal accuracy. This article delves into the background of centerless grinders, the motivation behind their DIY construction, and the emerging factories dedicated to producing these homemade machines.

Understanding Centerless Grinders

Centerless grinders are specialized machines that enable the grinding of cylindrical workpieces without the need for centering devices. Unlike conventional grinders, centerless grinders employ an uncentered setup wherein the workpiece is held between two rotating wheels – the grinding wheel and the regulating wheel. This unique configuration allows for continuous grinding operations, enhancing efficiency and productivity. These grinders are commonly used in various industries, including automotive, aerospace, and manufacturing, for tasks such as producing shafts, pins, and other cylindrical parts.

The DIY Culture and Motivation for Homemade Solutions

The growing trend of creating homemade machines stem from several factors. Firstly, hobbyists and small-scale manufacturers are seeking cost-effective alternatives to expensive commercial grinders. High-quality centerless grinders can be prohibitively expensive, making them inaccessible for many aspiring engineers and machinists. By constructing their own machines, enthusiasts can significantly reduce costs.

Secondly, the DIY aspect allows for customization. Every manufacturing requirement is unique, and having the ability to tailor a grinder to specific needs can lead to improved processes and results. This has led many skilled individuals to share their designs and experiences online, contributing to a vibrant community of makers dedicated to the art of machine-building.

homemade centerless grinder factories

Emerging Factories and Workshops

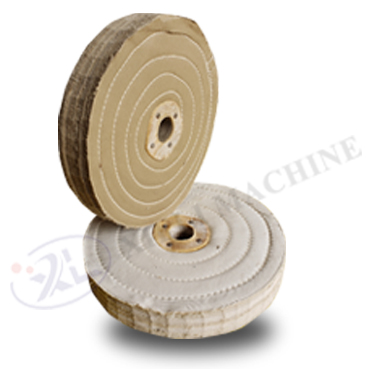

To meet the demand for homemade centerless grinders, several innovative factories and workshops have emerged. These establishments focus on supplying necessary components, kits, or guidance for enthusiasts looking to build their own machines. They often provide tailored solutions, stocking everything from grinding wheels to bearings and motors needed for the assembly.

These factories don't just stop at selling parts; many also offer workshops and training sessions. By providing hands-on experiences, they enable newcomers to learn the intricacies of grinding technology, machining practices, and safety protocols. This educational aspect fosters a culture of knowledge sharing, where experienced machinists mentor those eager to learn.

Moreover, the emergence of online platforms has facilitated the exchange of ideas and designs. Many DIY enthusiasts share blueprints, tutorials, and adjustments to improve upon existing designs. As a result, the centerless grinder community has become a collaborative space, where innovation thrives through shared experiences.

Conclusion

The rise of homemade centerless grinders highlights the intersection of creativity, engineering, and community in modern manufacturing. As enthusiasts take on the challenge of building their own machines, they are not only cutting costs but also fostering an environment of collaboration and knowledge sharing. The factories dedicated to supporting this movement are not just places for commerce; they are hubs of innovation, cultivating the next generation of machinists and engineers. In an age where DIY solutions are becoming increasingly popular, the centerless grinder's journey from manufacturing facility to homemade ingenuity exemplifies the spirit of modern craftsmanship.