Buffing and Polishing Machine Suppliers Elevating Surface Finish Quality

In today’s fast-paced manufacturing landscape, the quest for superior surface finishes is paramount. Buffing and polishing machines have become indispensable tools in various industries, including automotive, aerospace, metalworking, and jewelry making. These machines ensure that products not only meet aesthetic standards but also fulfill the functional requirements of precision and durability. As a result, the role of buffing and polishing machine suppliers is crucial in providing manufacturers with the equipment needed to achieve exceptional surface quality.

Understanding Buffing and Polishing Machines

Buffing and polishing machines are designed to refine the surface of materials, enhancing both appearance and performance. Buffing typically involves the use of a soft, textile or fiber wheel combined with an abrasive compound. This process removes minor imperfections and prepares the surface for polishing. On the other hand, polishing uses finer abrasives and may include various techniques like mechanical polishing, chemical polishing, and electro-polishing to achieve a high-gloss finish.

The effectiveness of these machines is largely determined by their design features, which include variable speed controls, powerful motors, and customizable attachments. A dynamic range of machines is available, from hand-held units for smaller tasks to industrial-grade machinery capable of processing large volumes of products. Understanding these critical factors can help businesses select the right machine for their specific applications.

The Role of Suppliers

Buffing and polishing machine suppliers play a vital role in the manufacturing process. They not only provide the machines but also offer essential support services such as maintenance, repairs, and parts replacement. A reliable supplier can make a significant difference in a company’s operational efficiency by ensuring that machines run smoothly and downtime is minimized.

Moreover, suppliers are crucial in educating clients about the best practices in buffing and polishing. They provide advice on the selection of materials and abrasives that complement the machines used, leading to optimal results. For example, they can recommend specific compounds that match the material being processed, whether it’s aluminum, stainless steel, or plastics.

Trends in the Buffing and Polishing Industry

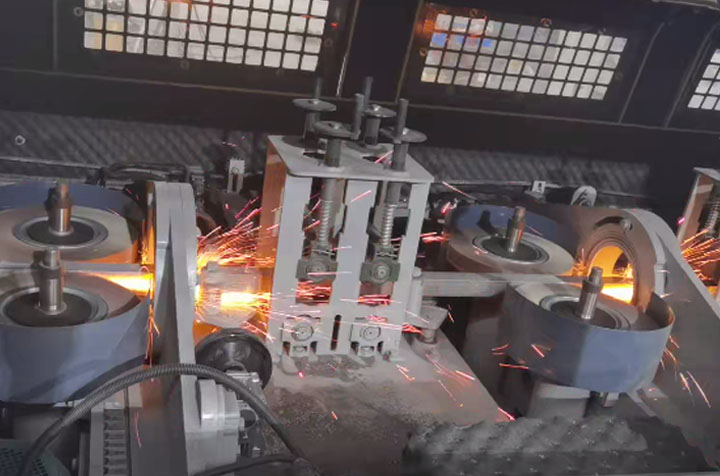

The buffing and polishing industry has evolved significantly with advancements in technology. Automation and smart technologies are becoming increasingly prevalent, allowing for more consistent finishes and higher productivity. Some suppliers now offer robotic buffing and polishing systems that can operate around the clock, significantly reducing labor costs and improving quality consistency.

buffing polishing machine supplier

Additionally, there has been a growing demand for eco-friendly polishing solutions. Many suppliers are now focusing on sustainable practices by offering biodegradable compounds and water-free polishing techniques. This shift is not only beneficial for the environment but also enhances the appeal of products to eco-conscious consumers.

Choosing the Right Supplier

Selecting a trustworthy buffing and polishing machine supplier is crucial for ensuring the longevity and performance of the equipment. Businesses should consider several factors when choosing a supplier

1. Reputation Look for suppliers with proven track records in the industry. Customer reviews and testimonials can provide valuable insights into a supplier's reliability and service quality.

2. Product Range A comprehensive range of machines allows manufacturers to find equipment tailored to their needs. It’s beneficial to select a supplier who can provide various options and advise on the best fit.

3. After-Sales Support A supportive after-sales service enhances the value of the initial purchase. Ensure that the supplier offers maintenance, training, and quick access to replacement parts.

4. Innovation and Technology Suppliers that invest in new technologies will likely provide more efficient and effective solutions, aligning with the latest advancements in the manufacturing environment.

Conclusion

As industries continue to prioritize quality and efficiency, the role of buffing and polishing machine suppliers becomes increasingly important. By providing high-quality machines, expert guidance, and essential support services, these suppliers help manufacturers achieve impeccable surface finishes that meet market demands. With the right equipment and supplier partnership, businesses can enhance their production capabilities, resulting in superior products that stand out in a competitive marketplace. As technology continues to evolve, staying informed about trends and advancements in buffing and polishing machinery will be key to maintaining a competitive edge.