The Growing Demand for Buffing and Polishing Machines A Guide for Exporters

In recent years, the global manufacturing and automotive industries have seen an increased demand for high-quality finishing processes. Buffing and polishing machines, essential for achieving a polished surface on various materials, have become a vital component in many production lines. As an exporter, understanding the market dynamics and technological advancements in this niche can help you capitalize on the growing demand.

Understanding Buffing and Polishing Machines

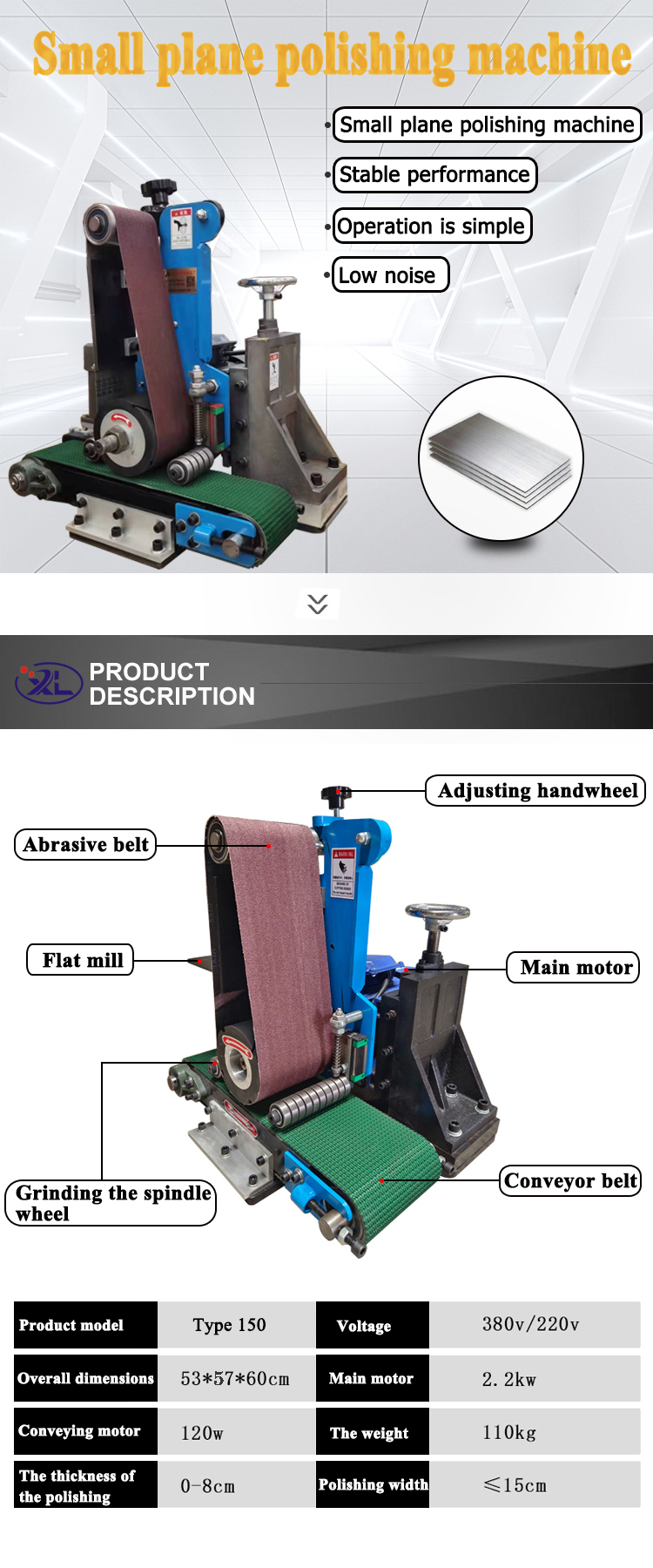

Buffing and polishing machines are used to enhance the surface finish of metals, plastics, wood, and other materials. These machines work by using abrasive compounds and buffs to remove surface imperfections, scratches, and oxidation, resulting in a high-gloss finish. The applications of these machines are vast, ranging from automotive parts and metal components to jewelry and household items.

There are several types of buffing and polishing machines available in the market, including bench-mounted units, portable tools, and automated systems. Each type has its unique advantages, catering to different industries and production requirements. As an exporter, it’s vital to offer a diverse range of options to meet the varied needs of your clients.

Exporting Buffing and Polishing Machines

When exporting buffing and polishing machines, it’s important to consider several factors that influence market entry and competitiveness

1. Market Research Conduct thorough market research to identify potential countries and industries that require buffing and polishing machines. Key markets include automotive, aerospace, electronics, and metalworking sectors. Understanding the trends and demands of these industries can help tailor your offerings.

buffing polishing machine exporter

2. Compliance and Standards Different countries have specific regulations and standards for machinery, especially regarding safety and emissions. Familiarizing yourself with these regulations ensures that your machines comply, minimizing potential legal issues and enhancing your credibility in the market.

3. Customization Offering customizable solutions can set you apart from competitors. Many industries require specialized machines tailored to their unique applications. By providing custom designs or modifications, you can meet specific customer needs and foster stronger partnerships.

4. Quality Assurance In the competitive market of buffing and polishing machines, quality is paramount. Ensure that your machines are manufactured using high-grade materials and advanced technologies. Implementing rigorous quality control processes can help in maintaining product integrity and reliability.

5. Digital Marketing and Online Presence In today’s digital age, having a strong online presence is essential. Invest in a professional website showcasing your products, specifications, and use cases. Leverage social media platforms and online advertising to reach potential customers worldwide. Establishing an informative blog or resource center can further position your brand as an industry authority.

6. Building Relationships Networking and building relationships within target markets can lead to valuable business opportunities. Attend industry trade shows, conventions, and exhibitions to connect with potential clients and distributors. Developing strong relationships with local partners can facilitate smoother market entry and distribution.

Conclusion

The buffing and polishing machine industry presents significant opportunities for exporters looking to expand their reach in global markets. By understanding the nuances of the industry, ensuring high-quality products, and leveraging effective marketing strategies, exporters can successfully navigate this competitive landscape. As industries continue to evolve and prioritize quality finishing processes, the demand for buffing and polishing machines is poised for growth, making now an ideal time to invest in this sector.