Understanding Buffing and Polishing Machine Price Lists

In today’s competitive manufacturing and service industries, the significance of surface finishing cannot be overstated. Whether in automotive, jewelry, or metalworking industries, the quality of a product heavily relies on its surface treatment. Buffing and polishing machines play a critical role in achieving the desired finish, and understanding their price lists is essential for businesses aiming to invest wisely in these tools. This article will delve into the factors influencing the price of buffing and polishing machines, the types available, and tips for making informed purchasing decisions.

Types of Buffing and Polishing Machines

Buffing and polishing machines come in various types, each tailored for specific applications. The most common types include

1. Bench-Top Buffing Machines These compact machines are ideal for small-scale operations or workshops. They provide essential buffing functions and are typically less expensive, ranging from $100 to $400, depending on the features.

2. Industrial Buffing Machines Designed for heavy-duty operations, these machines can handle larger components and extended usage. Prices can range from $1,000 to $5,000 or more, depending on power specifications, size, and additional features.

3. Portable Buffing Tools For those who require flexibility and mobility, portable buffing tools can be an excellent choice. Prices typically start at around $50 and can go up to $300 for high-quality models.

4. CNC Buffing and Polishing Machines These advanced machines utilize computer numerical control technology for precision and consistency. Due to their automation capabilities, they represent a significant investment, often costing between $10,000 and $50,000.

Factors Influencing Prices

Several factors contribute to the pricing of buffing and polishing machines

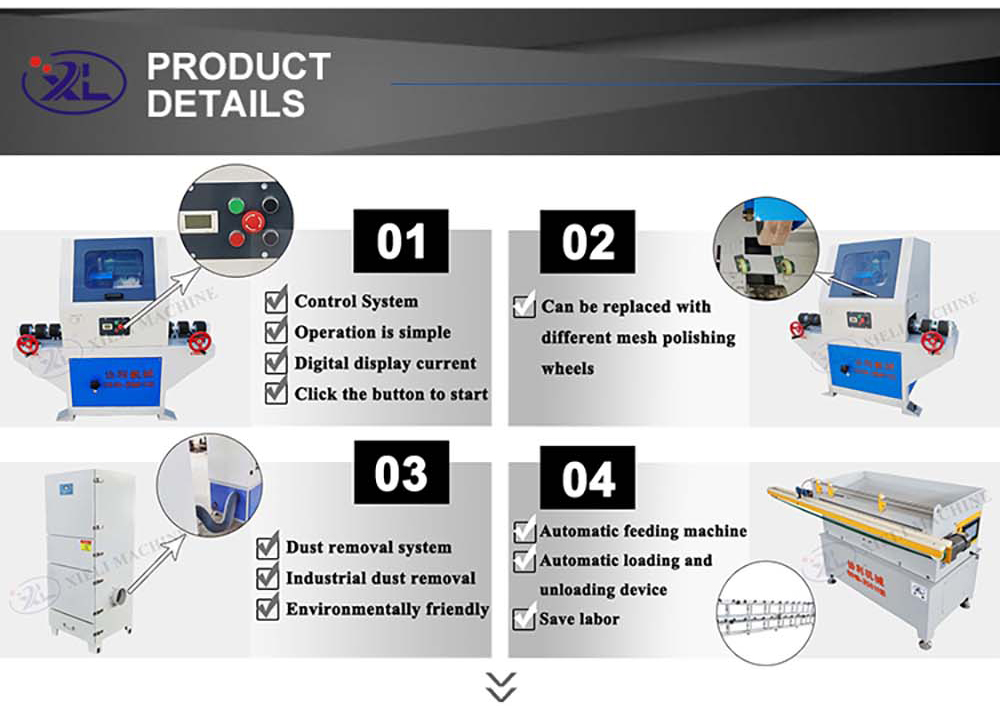

2. Power and Performance Machines with higher horsepower or specialized features—such as variable speed controls—tend to be more expensive. These features enhance efficiency and outcome quality.

buffing polishing machine pricelist

3. Materials and Construction Quality Durable materials lead to longevity and minimize service costs. Machines made with high-quality parts typically carry a higher price tag but can be more economical over time.

4. Brand Reputation Established brands offering warranty and customer support tend to charge more. However, investing in reputable brands can lead to superior performance and reliability.

5. Additional Features Features such as dust extraction, ergonomic designs, and automated systems increase both the functionality and cost of the machines.

Making Informed Purchases

When considering investing in buffing and polishing machines, it’s crucial to analyze specific needs and budget constraints. Here are some tips

1. Assess Your Application Requirements Identify the types of materials you will be working with and the desired finish quality. This will guide you in choosing the right machine type.

2. Research Brands and Models Read reviews, seek recommendations, and compare specifications. This comprehensive research will assist in selecting a machine that delivers value.

3. Consider Total Cost of Ownership Evaluate not just the purchase price, but factors like maintenance, operational costs, and potential downtime.

4. Request Quotes Reach out to multiple suppliers to obtain quotes and gauge the market rate for the specific machines you’re considering.

5. Explore Financing Options If upfront costs are a concern, look for suppliers offering financing plans or leasing options, which can make high-quality machines more accessible.

Conclusion

Navigating the buffing and polishing machine price list landscape requires thoughtful consideration of many factors. Understanding machine types, performance specifications, and market options equips buyers to make decisions that enhance operational efficiency and product quality. By investing the time to analyze needs and costs, businesses can secure the right machines that will yield exceptional finishing results for years to come.