Best Thru-Feed Centerless Grinder A Comprehensive Guide

In the world of precision machining, centerless grinders stand out as a vital tool for achieving high levels of accuracy and productivity. Among the various forms of centerless grinding, the thru-feed centerless grinder is particularly renowned for its efficiency and versatility. This article delves into the features, advantages, and best practices associated with the best thru-feed centerless grinders available in the market today.

What is a Thru-Feed Centerless Grinder?

A thru-feed centerless grinder is a type of grinding machine that allows the workpiece to pass through the grinding wheels continuously. In this setup, the workpiece is placed between a grinding wheel and a regulating wheel, which controls the speed and direction of the piece as it moves through the grinding process. This design eliminates the need for complex setups and fixtures, making it an optimal choice for high-volume production runs.

Key Features of Best Thru-Feed Centerless Grinders

1. Precision Grounding The best thru-feed centerless grinders come with precision-ground wheels that ensure consistent and accurate dimensions on the workpieces. This feature is crucial for industries where precision is non-negotiable.

2. High-Production Rates These grinders are designed for high efficiency, capable of processing multiple workpieces simultaneously. The continuous feed system allows for faster cycle times, significantly boosting productivity.

3. Adjustable Operating Parameters Modern thru-feed centerless grinders offer adjustable settings for wheel speed, feed rate, and grinding depth. This versatility enables operators to optimize the grinding process for different materials and designs.

4. User-Friendly Controls Advanced control systems and interfaces are a hallmark of top-tier thru-feed centerless grinders. These systems provide intuitive operation, real-time monitoring, and easy adjustments, reducing operator errors and training time.

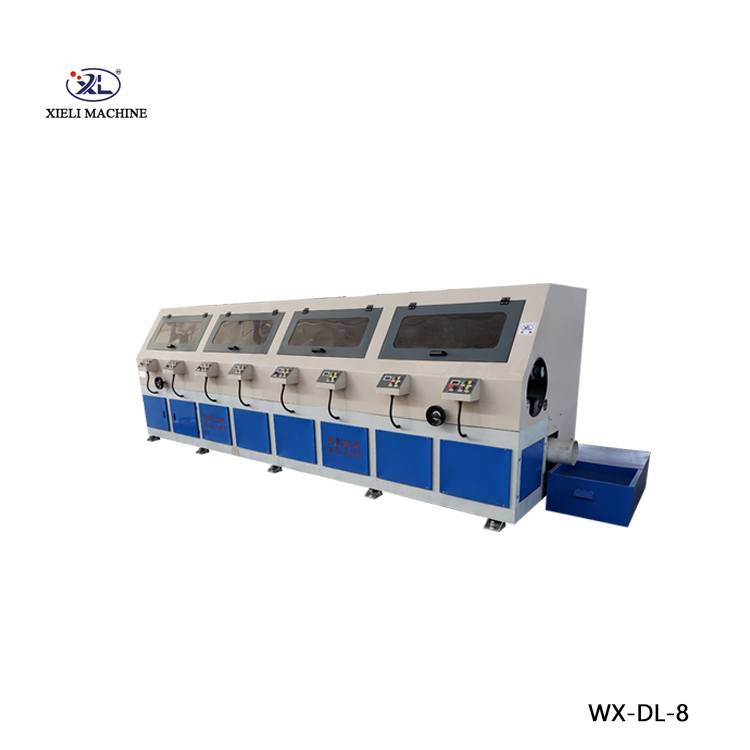

best thru feed centerless grinder

5. Robust Construction The best machines are constructed from high-quality materials to withstand the rigors of continuous operation. A sturdy base and durable components ensure minimal vibration and maximum precision during grinding.

Advantages of Thru-Feed Centerless Grinding

The benefits of utilizing a thru-feed centerless grinder are manifold

- Cost-Effectiveness By streamlining the grinding process, these machines contribute to lower operational costs due to reduced cycle times and labor requirements. - Consistency and Quality Thru-feed grinding promotes uniformity in finished products, essential for businesses that demand high-quality standards. - Space Efficiency These grinders often have a compact design, allowing for efficient use of available shop floor space.

Best Practices for Operating Thru-Feed Centerless Grinders

To maximize the potential of a thru-feed centerless grinder, operators should follow several best practices

- Regular Maintenance Implement a routine maintenance schedule to ensure optimal performance and longevity of the machine. - Proper Wheel Selection Choose the correct type and grade of grinding wheels suitable for specific materials to achieve desired results. - Monitor Workpiece Specs Keep a close eye on the specifications and tolerances of workpieces to ensure they meet the required standards.

Conclusion

The best thru-feed centerless grinders represent a pinnacle of efficiency and precision in modern manufacturing. With their advanced features and undeniable advantages, they are invaluable assets for any business focused on high-volume production and quality outcomes. By employing best practices and understanding their operation, companies can leverage these machines to enhance productivity and maintain a competitive edge in their respective industries.