The Best Customized CNC Centerless Grinders A Comprehensive Guide

In the realm of precision manufacturing, the importance of high-quality grinding equipment cannot be underestimated. Among the contenders in this category, CNC (Computer Numerical Control) centerless grinders stand out as a pivotal tool for achieving exceptional dimensional accuracy and surface finishes. The best customized CNC centerless grinders not only elevate the efficiency of production processes but also cater to the specific needs of diverse applications across various industries.

Understanding CNC Centerless Grinding

CNC centerless grinding is a process that allows for the grinding of cylindrical workpieces without the need for a supporting structure. This form of grinding utilizes two rotating wheels—an abrasive wheel and a regulating wheel—to remove material from the workpiece. This process is particularly beneficial for producing precision components at high volumes.

One of the defining features of contemporary CNC centerless grinders is their automation. By employing CNC technology, operators can program multiple parameters including wheel speed, feed rate, and grinding depth. This automation not only enhances consistency in production but also minimizes human error, leading to higher quality outcomes.

Why Customization Matters

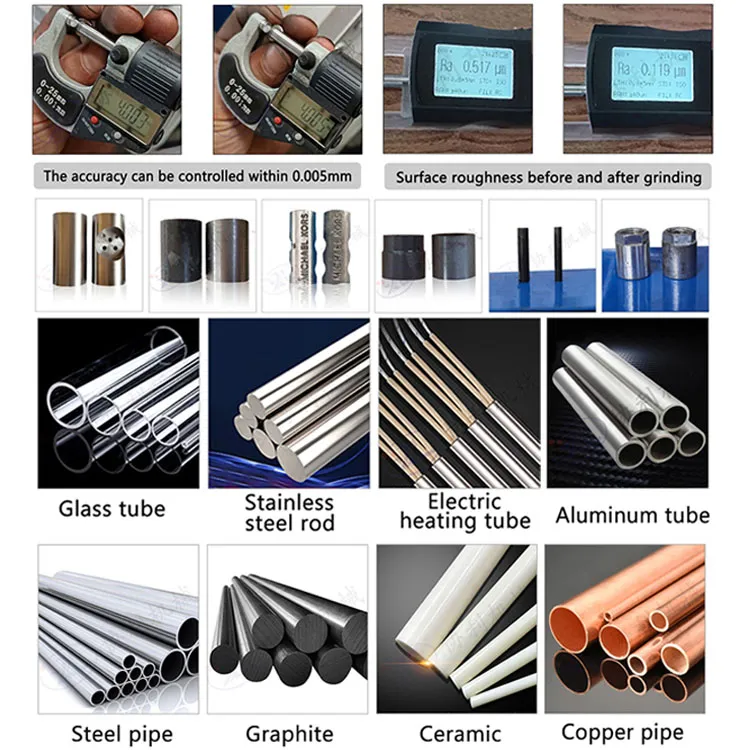

The landscape of manufacturing is continuously evolving, and with it, the necessity for customized solutions becomes apparent. Industries such as automotive, aerospace, medical, and tooling often require unique specifications that standard machines cannot fulfill. Customized CNC centerless grinders can be tailored to accommodate various sizes, shapes, and materials, making them invaluable in today’s bespoke manufacturing environment.

Customization can range from modifications in the spindle drive to the incorporation of advanced features such as adaptive control systems and advanced filtering mechanisms. These enhancements allow for more efficient material removal, less waste, and improved surface finishes, ultimately driving down production costs while enhancing product quality.

Key Features of Advanced CNC Centerless Grinders

1. Precision Engineering Top-tier CNC centerless grinders exhibit extraordinary precision, capable of achieving tolerances in the micrometer range. This level of precision is essential for sectors where safety and performance are critical, such as in aerospace components.

best customized cnc centerless grinder

2. User-Friendly Interfaces Modern machines often come equipped with intuitive interfaces and advanced software that simplifies operation and allows for easy programming of complex grinding cycles.

3. Multifunctionality Some customized grinders offer multifunctional capabilities, enabling operators to perform a variety of grinding tasks without needing to change setups frequently. This versatility significantly reduces downtime and boosts productivity.

4. Real-Time Monitoring The integration of IoT (Internet of Things) technologies in some CNC centerless grinders enables real-time performance monitoring. This feature allows for predictive maintenance, reducing the risk of unexpected breakdowns and increasing the operational lifespan of the machine.

5. Compliance with Industry Standards Customized solutions can be designed to adhere to stringent regulations pertinent to certain industries, ensuring reliability and safety during operation.

Choosing the Right Manufacturer

When considering an investment in customized CNC centerless grinders, selecting the right manufacturer is crucial. Look for companies with a proven track record of quality and customer satisfaction. Evaluate their capability to not only design and manufacture specialized equipment but also provide ongoing support and training for your team.

A reputable manufacturer will collaborate closely with you to understand your specific requirements and provide a solution that not only meets but exceeds your expectations.

Conclusion

In conclusion, the demand for best customized CNC centerless grinders reflects the broader trends in modern manufacturing. These machines represent the convergence of precision engineering, advanced technology, and bespoke solutions, tailored to meet the diverse needs of various industries. By investing in high-quality, customized equipment, manufacturers can enhance operational efficiency, improve product quality, and gain a competitive edge in the marketplace. As the industry continues to evolve, so too will the capabilities of CNC grinding technology, heralding a new era of precision manufacturing.