Best CNC Centerless Grinding Machines A Comprehensive Overview

In the realm of precision manufacturing, CNC centerless grinding machines stand out as essential tools for achieving high-quality surface finishes and tight tolerances. These machines play a critical role in industries ranging from automotive to aerospace, where the demand for precision parts is ever-increasing. This article explores the best CNC centerless grinding machines available, focusing on their features, applications, and advantages.

What is Centerless Grinding?

Centerless grinding is a method utilized to grind cylindrical workpieces without the need for a supporting structure. Unlike traditional grinding methods, where the workpiece is held between centers, centerless grinding uses two wheels the grinding wheel and the regulating wheel. The workpiece is fed between them, allowing it to be ground on its outer diameter while being simultaneously supported and driven. This process ensures high precision and efficiency, making it ideal for mass production.

Key Features of CNC Centerless Grinding Machines

1. Precision Control The CNC (Computer Numerical Control) feature allows for precise control over the grinding process. Programmable controls ensure that specifications are met consistently, reducing variability and enhancing repeatability.

2. Versatility Modern CNC centerless grinding machines can handle a variety of materials, including metals, plastics, and ceramics. This versatility enables manufacturers to use one machine for multiple applications, saving time and costs.

3. High Efficiency These machines are designed for high-speed operations, capable of achieving significant production rates. Automated feeding systems and cycle times can be optimized to maximize throughput.

5. Robust Construction The best CNC centerless grinding machines are built with heavy-duty materials that minimize vibration and enhance stability during operation. This construction leads to superior surface finishes and increased tool life.

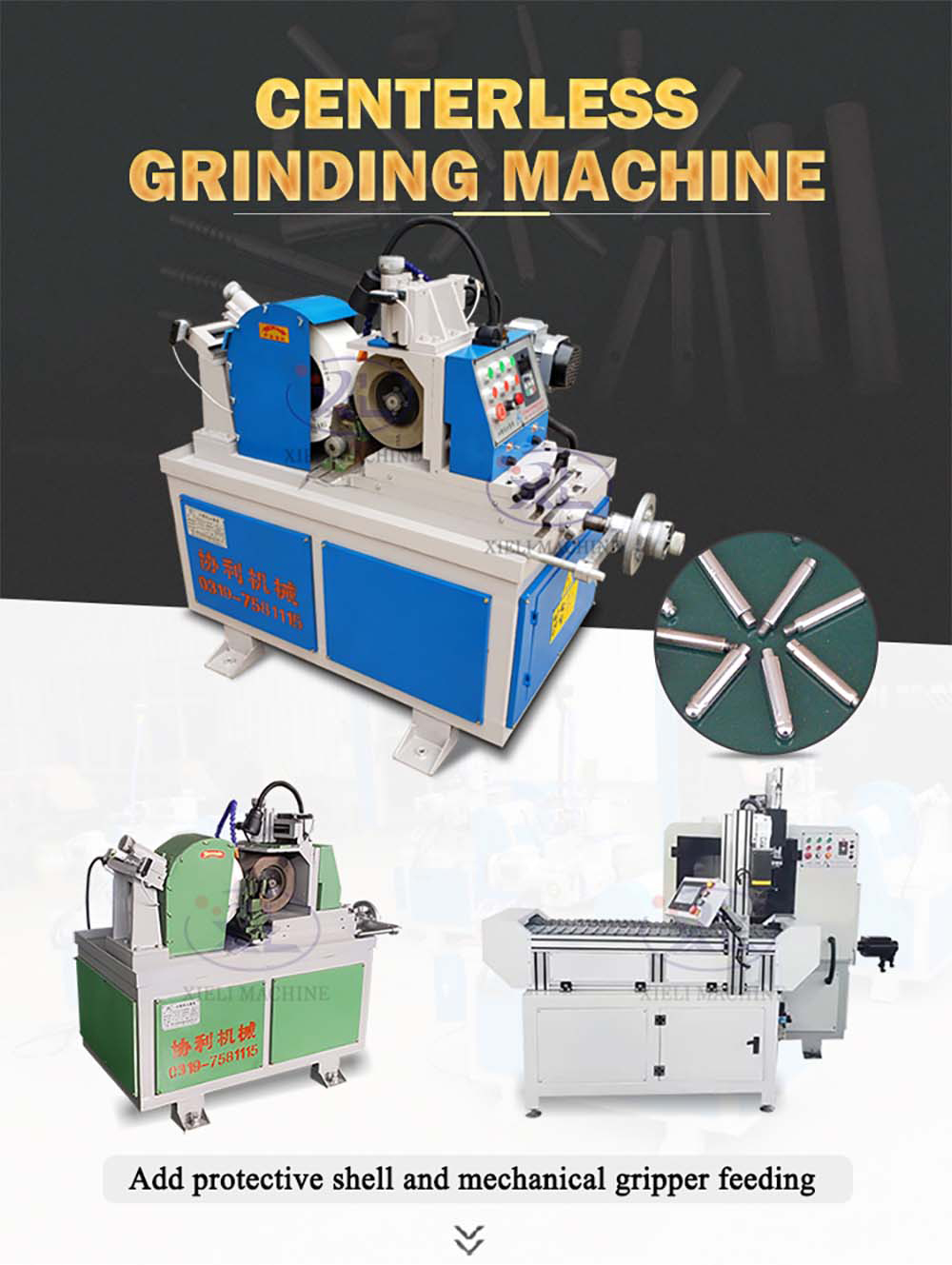

best cnc centerless grinding machine

Leading CNC Centerless Grinding Machines

1. Akron Ohio 600 Known for its user-friendly interface and powerful grinding capabilities, the Akron Ohio 600 features a rigid construction and advanced CNC controls. Its ability to handle complex profiles makes it a favorite among manufacturers looking for versatility.

2. Royal Master TG-12x4 This machine is celebrated for its precision and reliability. With an intuitive control system, it offers exceptional grinding accuracy and is capable of processing various materials efficiently, making it a preferred choice for the medical and automotive industries.

3. Monzesi G70 This Italian-made machine combines traditional craftsmanship with modern technology. The Monzesi G70 is recognized for its impressive productivity and ability to grind parts from very small to large diameters, ensuring flexibility for different production needs.

4. Koyo Machinery GKM Koyo's GKM series features advanced CNC capabilities, with synchronization between motors to optimize grinding operations. Its compact design is ideal for facilities with space constraints, without compromising on performance.

Applications of CNC Centerless Grinding Machines

CNC centerless grinding machines are widely used in various industries. Key applications include

- Automotive Components Such as axle shafts, fuel injectors, and valve components, where precise dimensions and surface finishes are critical. - Aerospace Parts Components like landing gear and structural parts, where safety and reliability demand high-quality manufacturing. - Medical Devices Producing precision instruments and implants that require stringent tolerances and surface finishes.

Conclusion

CNC centerless grinding machines represent a crucial investment for manufacturers aiming to enhance their production capabilities. With their precision, efficiency, and versatility, these machines enable industries to meet the stringent demands of modern manufacturing. As technology continues to advance, the future of CNC centerless grinding looks promising, offering even greater possibilities for innovation and efficiency in the manufacturing sector. When selecting a machine, it's essential to consider specific production needs, budget, and the potential for integration with existing systems to make the most informed decision.