The Best Cincinnati 220-8 Centerless Grinder A Comprehensive Overview

Centerless grinding is a crucial process in manufacturing that allows for the efficient and precise shaping of materials with minimal setup time. One of the standout machines in this domain is the Cincinnati 220-8 Centerless Grinder, renowned for its robust design and incredible performance. In this article, we will explore the features, benefits, and applications of this exceptional grinding machine.

Introduction to the Cincinnati 220-8

The Cincinnati 220-8 Centerless Grinder is part of Midwest's legendary lineup of machines that have served the manufacturing sector for decades. Known for its durability and efficiency, the 220-8 model features a straightforward operational process that can effectively grind a variety of workpieces, particularly in the production of round shapes.

Key Features

One of the most remarkable features of the Cincinnati 220-8 is its adaptability. The machine can handle a wide range of part sizes and materials, making it suitable for various industries. Its design allows for both infeed and through-feed grinding, catering to different production needs. Additionally, it possesses a robust structure that supports increased grinding pressure without compromising accuracy, resulting in enhanced productivity.

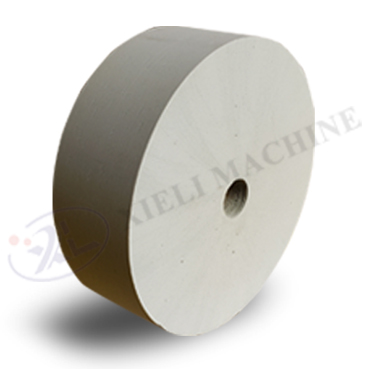

The Cincinnati 220-8 also boasts precision components, such as high-quality spindles and expertly crafted grinding wheels. These elements work together to provide consistent results, ensuring that manufactured parts meet exacting specifications. An easy-to-use control system allows operators to adjust grinding parameters seamlessly, which further enhances versatility.

Benefits of Using the Cincinnati 220-8

best cincinnati 220-8 centerless grinder

One of the primary advantages of the Cincinnati 220-8 Centerless Grinder is its efficiency. The machine's ability to perform high-speed grinding significantly reduces cycle times, allowing manufacturers to produce more parts within a shorter timeframe. This attribute is particularly beneficial for high-volume productions, where time and precision are essential.

Moreover, the Cincinnati 220-8 is designed for minimal maintenance, which translates to lower operational costs over time. With reliable components and a straightforward design, operators can spend less time on repairs and more on production. Additionally, the machine has a smaller footprint compared to some competitors, making it an ideal choice for facilities with limited space.

Applications

The Cincinnati 220-8 Centerless Grinder finds applications in various industries, including automotive, aerospace, and medical manufacturing. It is frequently employed to produce precision components like shafts, rods, and other cylindrical parts. Additionally, the grinder is effective in the production of materials like steel, aluminum, and other metals, showcasing its versatility.

In the automotive sector, for example, the ability to achieve tight tolerances is essential for component functionality and reliability. The Cincinnati 220-8 ensures that such requirements are met consistently, demonstrating its importance in critical manufacturing processes.

Conclusion

In conclusion, the Cincinnati 220-8 Centerless Grinder stands out as one of the best machines in its category due to its efficiency, precision, and versatility. Its robust design and user-friendly features make it an invaluable asset for manufacturers looking to enhance their productivity while maintaining high-quality standards. Whether in automotive manufacturing, aerospace, or any industry requiring precise cylindrical parts, the Cincinnati 220-8 remains a top choice for those seeking reliable centerless grinding solutions. With its long-standing reputation, it is no wonder that this machine continues to be a cornerstone in modern manufacturing processes.