Best Centerless Grinder Troubleshooting Tips

Centerless grinding is a vital manufacturing process that allows for the efficient and precise production of cylindrical parts. However, like any machinery, centerless grinders can encounter various issues that may hinder their performance. Effective troubleshooting techniques are essential for maintaining the efficiency and longevity of these machines. Below are some of the best practices for troubleshooting common problems in centerless grinding.

1. Identify the Symptoms

Before diving into troubleshooting, it’s crucial to identify the specific symptoms of the issue. Common signs of trouble might include inconsistent part dimensions, excessive noise, vibration, or even complete machine failure. Take detailed notes on the machine's performance and any unusual behaviors. This step will help you narrow down the potential causes and find solutions more efficiently.

2. Check Wheel Alignment

One of the primary causes of dimensional inaccuracies is improper wheel alignment. Misaligned grinding wheels can lead to uneven cuts, resulting in out-of-spec parts. To troubleshoot this

- Visual Inspection Start by visually inspecting both the regulating and grinding wheels. Make sure they are parallel and properly aligned according to the manufacturer’s specifications. - Adjustments Adjust the wheel angles if necessary. Most centerless grinders come with adjustment mechanisms specifically designed to fine-tune wheel alignment.

Always remember to recalibrate the machine after making any adjustments

.3. Inspect Workpiece Support

The support mechanisms play a crucial role in guiding the workpiece during the grinding process. A malfunction here can cause instability, leading to defects. Check the following

- Feed System Ensure that the feed mechanism is functioning smoothly. Look for any obstructions or worn parts that may affect the feed rate. - Bar Stock Support Inspect the support system for any signs of wear or damage. Properly adjusted support can drastically improve the consistency of the parts.

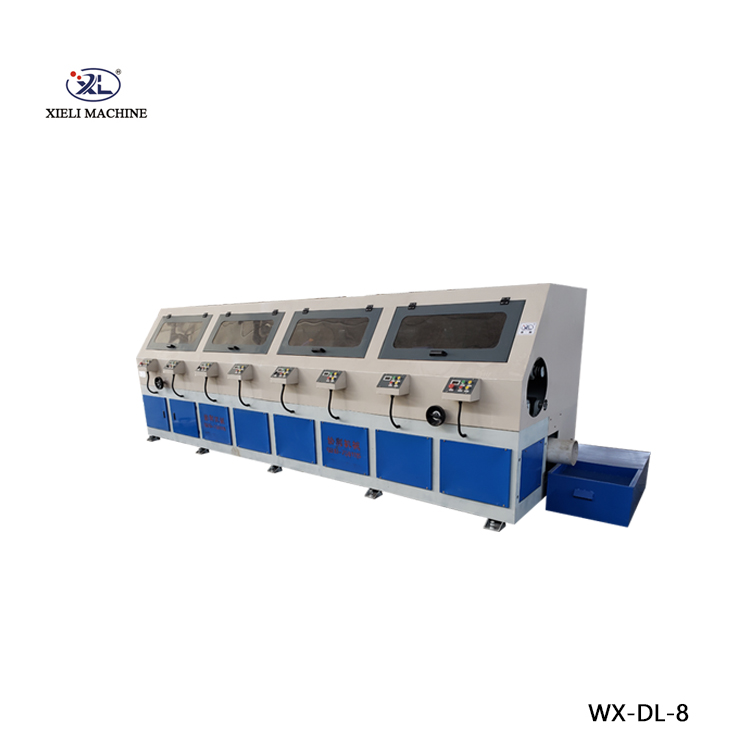

best centerless grinder troubleshooting

4. Monitor Wheel Condition

The grinding wheel's condition is critical in achieving optimal performance. A worn or damaged wheel can lead to poor surface finishes or even part rejection. Regularly monitor these aspects

- Wear Patterns Look for uneven wear or glazing on the wheel surface. If noticeable, it's time to dress or replace your grinding wheel. - Dressing Tools Utilize appropriate dressing tools to refresh the wheel’s surface, ensuring it remains effective throughout the grinding process.

5. Examine Coolant System

Coolant plays an essential role in both lubrication and heat dissipation during grinding. An inadequate coolant system can lead to overheating and subsequent damage. Pay attention to

- Flow Rate Make sure the coolant is being delivered at an adequate flow rate to the work area. - Quality of Coolant Check the coolant for contamination or degradation. Regularly change your coolant to maintain its effectiveness.

6. Review Machine Settings

Lastly, verify that the machine settings match the requirements for the specific part being produced. Small errors in settings can lead to significant defects. Consider

- Speed Settings Double-check the rotational speeds of the grinding and regulating wheels. - Dress Angle and Depth Ensure the dressing angles and depths are set according to specifications for the particular job.

Conclusion

Troubleshooting a centerless grinder effectively requires a comprehensive understanding of how various components work together. Regular maintenance, diligent monitoring, and timely adjustments can prevent most issues from escalating. Following these best practices will not only enhance the performance of your centerless grinder but also maximize the efficiency and quality of your production process. By addressing these points, operators can ensure a seamless grinding operation, thus leading to improved productivity and reduced downtime.