Best Centerless Grinder Troubleshooting Tips

Centerless grinders are essential in modern manufacturing, providing high precision and efficiency for workpiece finishing. However, like any machine, they are susceptible to issues that can affect performance and output quality. Below are some common problems encountered with centerless grinders and tips for troubleshooting them effectively.

1. Inconsistent Part Diameter

One of the most frequent issues with centerless grinders is inconsistent part diameter. This can occur due to improper setup, incorrect wheel alignment, or worn-out grinding wheels. To troubleshoot, start by checking the wheel alignment. Both the regulating wheel and the grinding wheel should be properly aligned to ensure the workpiece is being held at the correct angle. Additionally, inspect the grinding wheel for signs of wear; if it seems uneven or worn down, replace it to maintain uniformity in diameter.

Another common problem is workpiece skewing during the grinding process. This can result from incorrect adjustment of the regulating wheel pressure or improper work rest placement. To fix this issue, adjust the regulating wheel pressure to ensure even force is applied across the workpiece. Make sure the work rest is positioned correctly to support the workpiece without allowing it to tilt.

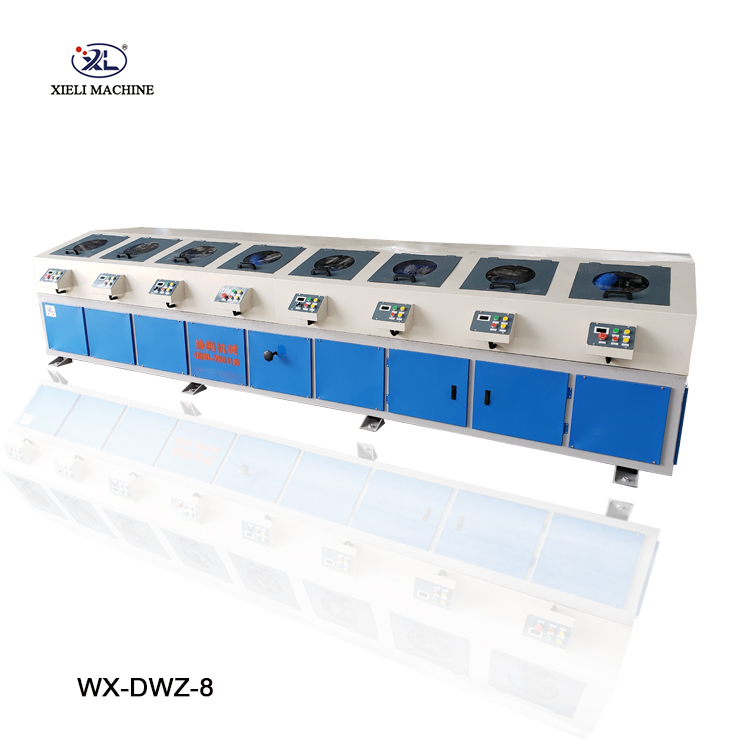

best centerless grinder troubleshooting

3. Variation in Surface Finish

A poor surface finish can be attributed to several factors, including an unbalanced grinding assembly, incorrect wheel speed, or contamination of the grinding wheel. To address surface finish issues, start by checking the balance of your grinding wheels, and replace any wheels that are out of balance. Ensure the grinding speed is within the recommended parameters for the material you are working with. Lastly, clean the wheel frequently to remove any buildup that can impact performance.

4. Overheating of the Workpiece

Excessive heat can damage both the workpiece and the grinding wheel, leading to potential failures. Overheating may occur due to insufficient coolant flow or excessive grinding pressure. To troubleshoot this, verify that your coolant system is functioning optimally, and adjust the flow rate if necessary. Additionally, review the grinding pressure and reduce it if it appears too high for the material being processed.

Conclusion

Troubleshooting a centerless grinder requires a methodical approach to identify and rectify issues efficiently. By regularly maintaining your equipment and understanding common problems, manufacturers can ensure their centerless grinders operate at optimal performance levels, leading to increased productivity and higher-quality output. Regular checks and adjustments will contribute significantly to the longevity and reliability of your grinding operations.