Best Centerless Grinder Tables Enhancing Precision and Efficiency

When it comes to machining processes, centerless grinding is a widely recognized method for achieving high precision and efficiency. This technique eliminates the need for a fixture, allowing for the continuous feeding of workpieces into the grinding area. One essential element that significantly impacts the performance of centerless grinding is the table on which the machine operates. In this article, we explore some of the best centerless grinder tables available in the market, their features, and how they enhance the overall grinding process.

The Importance of Grinder Tables

The table of a centerless grinder serves multiple purposes. It provides a stable base for the machine, supports the workpiece during the grinding process, and helps maintain the desired alignment and positioning. A well-designed centerless grinder table can improve accuracy, reduce vibrations, and increase the overall efficiency of the grinding operation. Therefore, selecting the right table is crucial for achieving optimal grinding results.

Key Features of High-Quality Centerless Grinder Tables

1. Sturdy Construction Quality centerless grinder tables are typically made from high-strength materials such as cast iron or steel. This sturdiness minimizes vibrations and ensures that the workpiece remains stable during grinding. A robust table will also withstand the wear and tear of daily operations, making it a worthwhile investment for any machining facility.

best centerless grinder tables

2. Precision Alignment Options Many top-tier centerless grinder tables include adjustable features to ensure precise alignment of the workpiece. This capability allows operators to make minute adjustments based on the grinding requirements, which is essential for achieving the perfect finish and tolerances. Some advanced models even offer digital positioning systems for added accuracy.

3. Integrated Coolant Systems Heat generation is a significant concern in grinding operations. High-quality tables often come equipped with integrated coolant systems that help maintain the optimal temperature during grinding. This feature not only prolongs the lifespan of the grinding wheel but also enhances the quality of the workpiece by preventing thermal distortion.

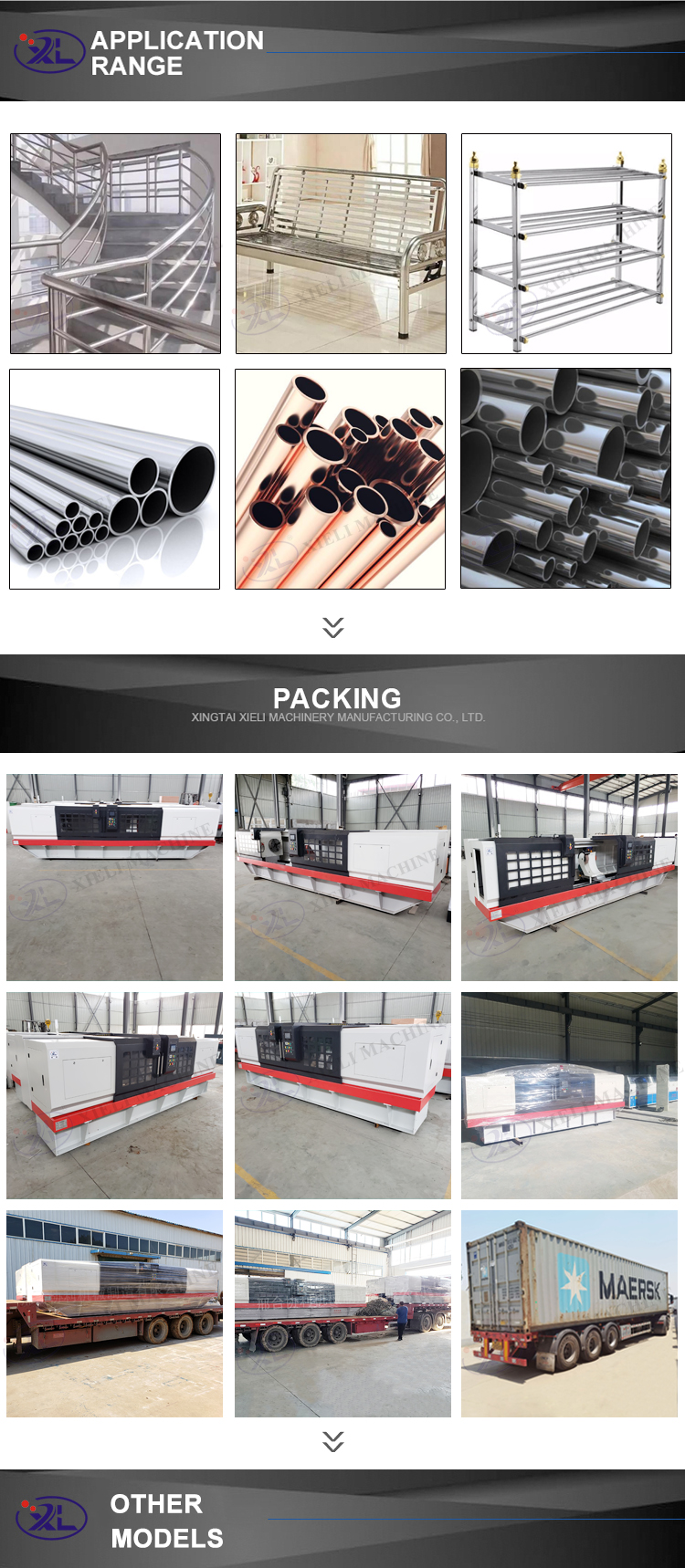

4. Versatility The best centerless grinder tables are designed to accommodate a wide range of workpiece sizes and shapes. This versatility is crucial for manufacturing operations that deal with various materials and components. A table that can easily adapt to different setups enables manufacturers to use their equipment for various applications without needing extensive modifications.

5. User-Friendly Design Ease of use is another important consideration. The best centerless grinder tables feature intuitive controls and easy access to adjustments, allowing operators to set up and optimize the grinding process efficiently. Features such as quick-release mechanisms can save valuable time during production runs and tool changes.

Conclusion

In summary, selecting the right centerless grinder table is essential for achieving high performance and precision in grinding operations. Key features like sturdy construction, precision alignment options, integrated coolant systems, versatility, and user-friendly design are critical factors to consider when making a purchase. Investing in a high-quality centerless grinder table not only enhances the overall efficiency of machining processes but also contributes to the production of superior quality workpieces. As industries continue to seek ways to boost productivity and quality, the importance of choosing the best centerless grinder table remains paramount.