The Best Acme Centerless Belt Grinder A Comprehensive Overview

In the realm of precision machining, the choice of equipment can significantly impact the quality and efficiency of the manufacturing process. One of the most crucial tools in this domain is the centerless belt grinder. Among the various options available in the market, the Best Acme Centerless Belt Grinder stands out due to its innovative design, exceptional performance, and versatility.

Understanding Centerless Belt Grinders

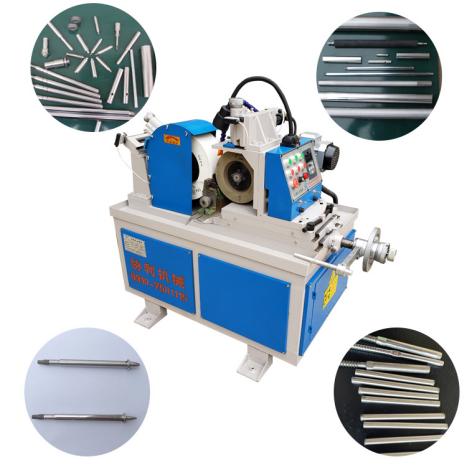

Centerless belt grinders are specialized machines designed for the efficient grinding of cylindrical parts without the need for requiring centers or fixtures. This method allows for continuous workpiece feed, significantly enhancing productivity. The unique configuration of these grinders ensures a consistent grind, making them ideal for various applications, including automotive, aerospace, and manufacturing industries.

Key Features of the Best Acme Centerless Belt Grinder

1. Superior Performance The Best Acme model is engineered to deliver high-speed grinding while maintaining precision. Its powerful motor and robust construction ensure that it can handle the toughest jobs, from rough grinding to precise finishing.

2. User-Friendly Design Operating a centerless belt grinder can be daunting for beginners. However, the Best Acme model features an intuitive control interface, making it accessible for operators of all experience levels. The ease of use means less training time and more efficient production.

best acme centerless belt grinder

3. Versatility One of the standout aspects of the Best Acme Centerless Belt Grinder is its versatility. It can accommodate a variety of materials, including steel, aluminum, and plastics. This adaptability makes it a valuable asset in any workshop where diverse materials are processed.

4. Maintenance Efficiency Regular maintenance is key to ensuring the longevity and performance of any machinery. The Best Acme grinder is designed with easy access to critical components, enabling swift maintenance and minimizing downtime. This feature is particularly advantageous for high-volume production environments.

5. Safety Features In manufacturing environments, safety cannot be compromised. The Best Acme model incorporates several safety features, including protective guards and emergency stop buttons, prioritizing the safety of the operator while maximizing productivity.

Applications in Various Industries

The versatility of the Best Acme Centerless Belt Grinder allows it to be utilized across numerous industries. In the automotive sector, it is used for grinding axles and shafts, ensuring they meet strict tolerance requirements. In aerospace, it handles the delicate task of grinding components for aircraft engines, where precision is paramount. Additionally, manufacturers benefit from its ability to prepare components for coating or finishing processes, demonstrating its all-encompassing functionality.

Conclusion

In conclusion, the Best Acme Centerless Belt Grinder represents a significant investment for businesses seeking to enhance their machining capabilities. With its superior performance, user-friendly design, and versatility across various applications, it proves to be an indispensable tool in modern manufacturing. As industries continue to evolve and demand greater efficiency and precision, having a reliable centerless belt grinder like the Best Acme at your disposal is not just an advantage; it’s a necessity. Embracing such advanced machines facilitates optimization in production processes, ultimately contributing to the growth and success of manufacturing operations.