The Best Round Tube Polishing Machines Enhancing the Finish with Precision

In the world of metalworking and fabrication, the significance of a smooth, polished finish cannot be overstated. For many industries that rely on stainless steel, aluminum, or other metals, achieving a perfect surface finish is vital not only for aesthetic reasons but also for functionality and corrosion resistance. This is where the best round tube polishing machines come into play.

Understanding Tube Polishing

Tube polishing involves the use of specialized machines to enhance the surface finish of tubular materials. These tubes, typically used in various applications ranging from automotive to architectural structures, require a polished surface to improve durability, reduce friction, and maintain hygiene standards. A well-polished tube not only looks appealing but also ensures that it performs efficiently in its intended application.

Characteristics of the Best Round Tube Polishing Machines

When seeking the best round tube polishing machines, there are several key features to consider

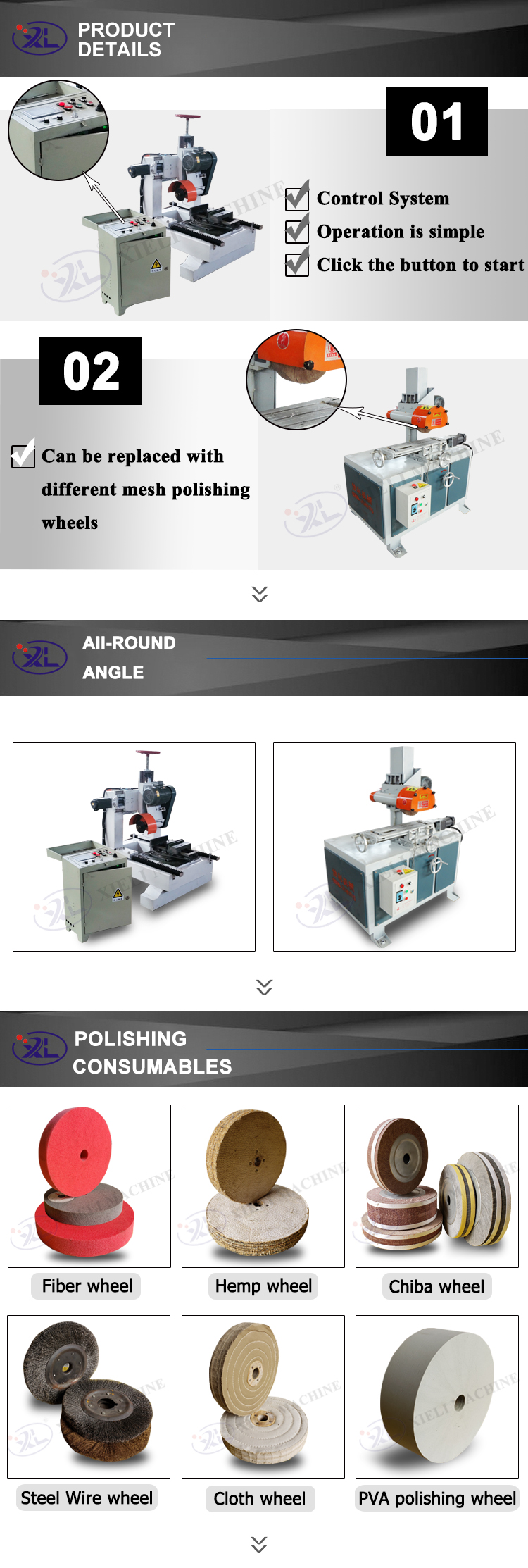

1. Versatility The ideal polishing machine should be able to handle different tube sizes and materials. Whether dealing with small or large diameters, the machine should easily accommodate any tube shape without compromising the quality of the polish.

2. Efficiency Time is money in the manufacturing world. The best machines maximize productivity by providing quick and efficient polishing processes. High-speed motors and optimized polishing techniques are crucial for reducing cycle times while maintaining a high standard of finish.

3. Quality of Finish Ultimately, the purpose of any polishing machine is to achieve a superior finish. The best machines employ advanced polishing techniques, such as using varying grades of abrasives, that can transform a rough surface into a mirror-like finish.

best round tube polishing machine

4. User-Friendly Design Ease of operation is essential, especially in high-volume production environments. Machines that feature intuitive controls, adjustable settings, and ergonomic designs promote efficient operation and reduce the learning curve for new operators.

5. Durability and Maintenance Long-lasting equipment is a worthy investment. The best machines are constructed from high-quality materials that withstand the rigors of daily use. They should also be designed for easy maintenance, ensuring longevity and consistent performance.

Popular Techniques in Tube Polishing

Several techniques are commonly employed in round tube polishing

- Mechanical Polishing This involves the use of abrasive belts or discs to mechanically remove surface imperfections. It is suitable for achieving a high degree of polish on various metal surfaces.

- Electropolishing A more advanced method, electropolishing is an electrochemical process that enhances the finish by removing a thin layer of material from the surface. This technique is particularly effective for stainless steel tubes, providing excellent corrosion resistance.

- Vibratory Finishing This method utilizes abrasive media and vibrations to smooth out metal surfaces. It is not limited to tubes and can be used for various shapes and sizes, making it a versatile option in polishing applications.

Conclusion

In conclusion, the best round tube polishing machines are essential tools for any metalworking shop aiming to achieve superior surface finishes. By focusing on features such as versatility, efficiency, finish quality, user-friendliness, and durability, manufacturers can select the right equipment to meet their needs. As technology continues to advance, the evolution of polishing machines promises even greater enhancements in metal finishing, paving the way for increased productivity and product quality in various industries. Investing in the best round tube polishing machines not only improves aesthetics but also enhances the overall performance and longevity of the final products.