The Surge of Belt Polishing Machine Exporters A Global Perspective

In recent years, the demand for industrial machinery, particularly belt polishing machines, has surged globally. These machines play a crucial role in the manufacturing process across various industries, such as metalworking, woodworking, and automotive manufacturing. Their ability to deliver high-quality finishes on surfaces makes them indispensable tools for businesses aiming to achieve excellence in their product offerings. Consequently, the rise of belt polishing machine exporters has become a significant trend, shaping the landscape of global trade in industrial machinery.

The Role of Belt Polishing Machines

Belt polishing machines are designed to smooth and finish surfaces by utilizing an abrasive belt. This mechanism allows for uniform finishing across different materials, including metals, plastics, and wood. The versatility of these machines enables their application in various sectors, including furniture production, automotive refinishing, and metal fabrication. With industries increasingly focused on quality and precision, the demand for reliable belt polishing machines has spiked, creating opportunities for exporters who specialize in this niche market.

Export Dynamics

The market for belt polishing machines is not confined to any single region. Countries with robust manufacturing industries, such as China, Germany, and the United States, have emerged as key players in the export of these machines. Chinese manufacturers, in particular, have established themselves as leaders in both production and exportation, offering competitive pricing and a wide range of models. German and American companies, known for their engineering excellence, cater to clients looking for high-end solutions that promise durability and efficiency.

The dynamics of international trade in belt polishing machines are influenced by various factors, including technological advancements, economic growth in emerging markets, and the global push for sustainability. As more countries invest in manufacturing infrastructure, the demand for sophisticated machinery, including belt polishing machines, continues to rise. Exporters must navigate complex regulations and trade agreements, as well as adapt to the needs of different markets to remain competitive.

Challenges in the Export Market

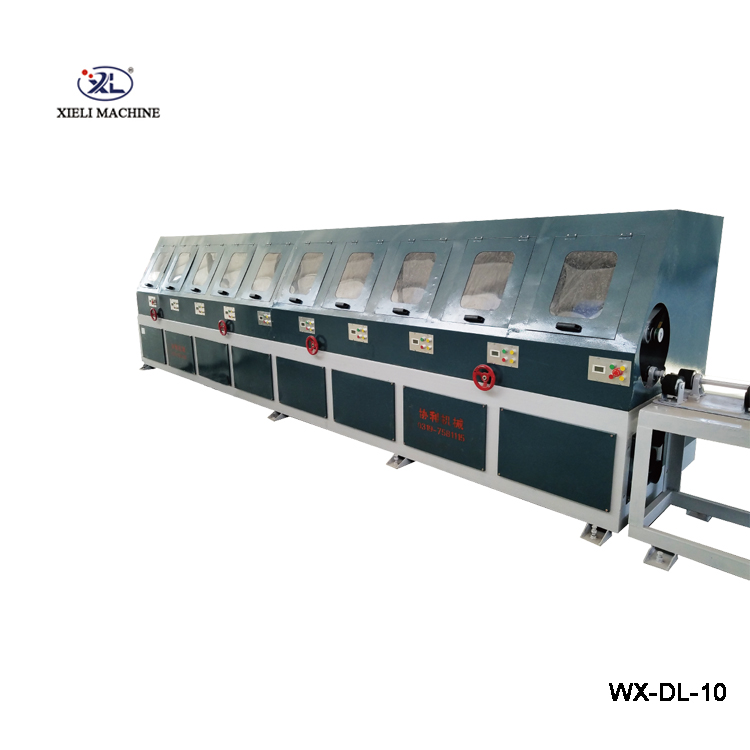

belt polishing machine exporters

While the prospects for belt polishing machine exporters are promising, they are not without challenges. One of the primary concerns is the fluctuation of raw material prices, which can significantly impact manufacturing costs. Additionally, exporters must contend with increased competition, both from established brands and new entrants eager to capitalize on the growing market.

Another challenge lies in ensuring product quality and meeting international standards. As customers become more discerning, they expect not only high-performance machines but also adherence to safety and quality certifications. Exporters must invest in research and development to innovate and improve their product offerings continuously.

Furthermore, navigating logistics and supply chain disruptions, especially in the wake of global events like the COVID-19 pandemic, poses a challenge for exporters. Ensuring timely delivery can be crucial for maintaining client relationships and fulfilling contracts.

Future Trends

Looking ahead, the future of belt polishing machine exporters appears bright, with several trends likely to shape the industry. One noticeable shift is the growing emphasis on automation and smart technology in manufacturing. As industries embrace Industry 4.0, belt polishing machines integrated with advanced technologies, such as Artificial Intelligence (AI) and Internet of Things (IoT), are expected to gain traction. These innovations can improve efficiency, reduce human error, and provide valuable data analytics for businesses.

Sustainability is another driving force. There is an increasing demand for eco-friendly machines and production processes. Exporters who prioritize sustainable practices and develop energy-efficient models will have a competitive edge in the market.

Conclusion

The belt polishing machine export market is witnessing robust growth, driven by increasing demand across various industries and advancements in technology. While challenges remain, the opportunities for exporters are numerous. By focusing on innovation, quality, and sustainability, exporters can navigate this dynamic landscape and play a vital role in fulfilling the growing needs of global manufacturers. As the industry evolves, those who adapt to changing market demands will likely emerge as leaders in the belt polishing machine export sector.