Understanding Bar Centerless Grinders An Essential Tool in Manufacturing

In the realm of manufacturing, precision and efficiency are paramount. One crucial piece of equipment that meets these demands is the bar centerless grinder. This specialized machine is designed to grind cylindrical parts without the need for a center support, optimizing both the speed and accuracy of the grinding process.

A bar centerless grinder operates on the principle of supporting the workpiece between two rotating grinding wheels—a regulating wheel and a grinding wheel. The regulating wheel controls the speed and the axial movement of the workpiece while the grinding wheel removes material, achieving the desired finish. This arrangement allows for continuous flowing of bars through the grinding zone, making it an excellent choice for high-volume production runs.

One of the primary advantages of using a bar centerless grinder is its ability to handle long workpieces with minimal input from operators. Traditional grinders often require complex fixturing or setups, whereas centerless grinders require less setup time and can process multiple pieces simultaneously. This not only increases production efficiency but also reduces labor costs, making it a preferred choice for manufacturers focused on high-volume output.

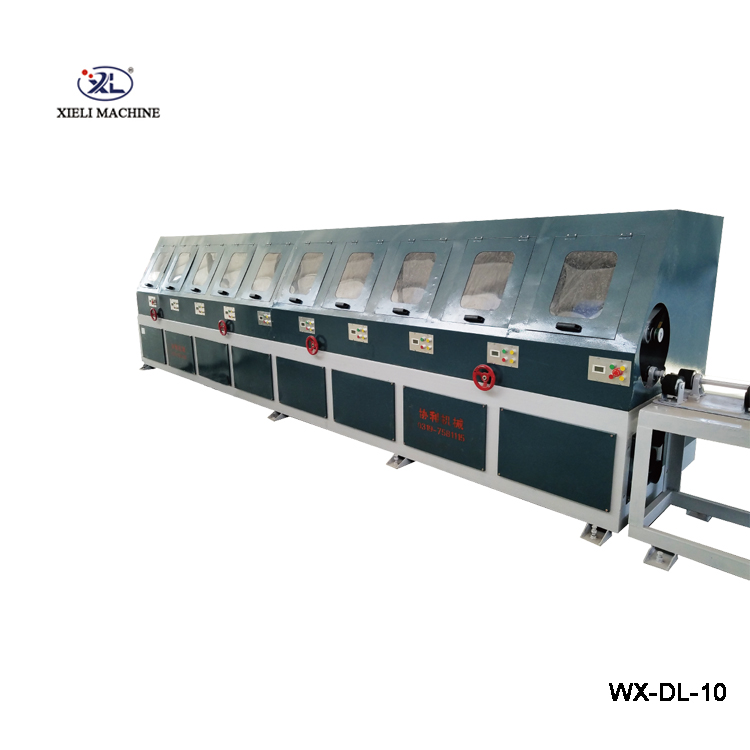

bar centerless grinder products

Moreover, bar centerless grinders are versatile and adaptable. They can efficiently grind various materials, including metals, plastics, and composites, catering to industries ranging from automotive to aerospace. The precision achieved through centerless grinding results in tight tolerances, which are crucial for parts that must fit seamlessly into complex assemblies.

Another significant factor is the reduced risk of part damage. In centerless grinding, the workpiece is not clamped, minimizing the risk of distortion that can occur with traditional grinding methods. This feature is particularly beneficial when working with delicate materials or when maintaining tight tolerances is essential.

For manufacturers looking to enhance their operational efficiency, investing in a bar centerless grinder can yield significant returns. Not only does it increase production capabilities, but it also ensures a higher level of quality control. Most modern grinders are equipped with advanced technology and automation systems that allow for real-time monitoring and adjustments, further improving output quality and consistency.

In conclusion, bar centerless grinders represent a vital piece of technology in the manufacturing landscape. Their ability to grind parts quickly and with high precision makes them indispensable for industries that demand high-quality machined components. As technology advances and the manufacturing sector continues to evolve, the importance of such equipment will only increase, paving the way for more innovative manufacturing solutions. Whether for small-scale projects or large automotive assemblies, incorporating a bar centerless grinder can significantly enhance a company's productivity and output quality.