Exploring the World of Bar Centerless Grinders A Deep Dive into Precision Engineering

In the competitive landscape of manufacturing and precision engineering, the bar centerless grinder has emerged as a critical tool for ensuring the high-quality production of cylindrical components. These machines are designed specifically to grind bars and shafts to exacting specifications without the need for chucks, jigs, or fixtures, delivering efficiency and precision at every turn.

The Mechanics of Centerless Grinding

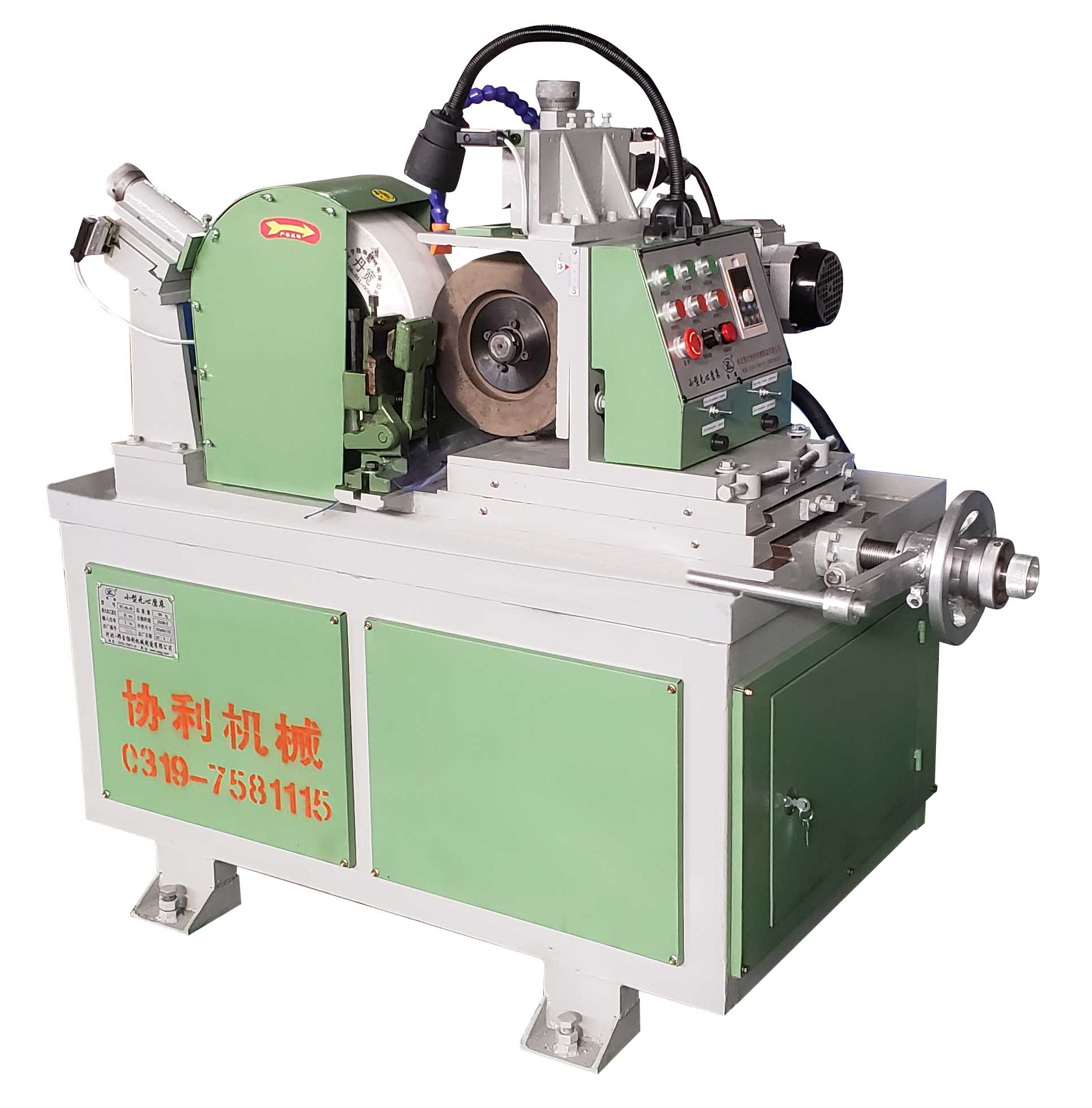

At the heart of a bar centerless grinder lies a unique process known as centerless grinding. Unlike conventional grinding methods, which rely on centers to hold the workpiece, centerless grinding supports the workpiece on a stationary platform or a support blade while the grinding wheel and regulating wheel rotate around it. This setup allows for continuous production since multiple pieces can be processed simultaneously, resulting in increased throughput.

The key components of a centerless grinder include the grinding wheel, which does the heavy lifting of material removal, and the regulating wheel, which controls the feed rate and rotational speed of the workpiece. The adjustment of these components can drastically affect the precision and finish of the final product, making operator skill and machine configuration paramount.

Advantages of Bar Centerless Grinding

One of the primary advantages of bar centerless grinding is its ability to produce a high volume of parts with consistent quality. This is particularly important in industries such as automotive, aerospace, and medical, where precision is non-negotiable. Traditional grinding techniques can introduce variances and imperfections that compromise the integrity of components, whereas centerless grinding minimizes such risks.

Additionally, the lack of centering mechanisms means that bar centerless grinders can handle longer workpieces without sacrificing accuracy. This flexibility makes them ideal for manufacturers who deal with a wide variety of sizes and shapes. Moreover, the setup time is significantly reduced compared to traditional grinding methods, allowing manufacturers to switch between different jobs with little downtime.

bar centerless grinder company

Applications Across Industries

Bar centerless grinders are employed in various industries for their versatility and efficiency. In the automotive sector, they are used to produce precision parts such as tappets, camshafts, and axles. The aerospace industry relies on these machines for components that must withstand extreme conditions and adhere to strict regulatory standards. Even in the medical field, centerless grinding is crucial for producing surgical instruments and implants with exacting tolerances.

The versatility of these machines extends beyond simply grinding. Many modern bar centerless grinders come equipped with additional capabilities such as polishing, which can further reduce the need for secondary operations. This integration streamlines production processes and contributes to overall cost savings for manufacturers.

The Future of Bar Centerless Grinding

As technology continues to evolve, so too do the capabilities of bar centerless grinders. The introduction of automation and smart technology is transforming these machines into highly efficient production tools. With the integration of sensors and advanced software, modern grinders can monitor their own performance, identify maintenance needs in real-time, and optimize production workflows without human intervention.

Furthermore, the increasing emphasis on sustainability and energy efficiency in manufacturing is prompting manufacturers to invest in greener grinding solutions. New materials, smarter designs, and energy-efficient motors make contemporary centerless grinders more environmentally friendly.

Conclusion

Bar centerless grinders represent a cornerstone of precision engineering, offering manufacturers the ability to produce high-quality components with speed and efficiency. Their unique grinding process, adaptability across industries, and ongoing advancements in technology make them indispensable in modern manufacturing settings. Companies that invest in high-quality centerless grinding solutions stand to significantly enhance their productivity and product quality, positioning themselves favorably in an ever-evolving market. As the demand for precision continues to grow, bar centerless grinders are set to play a vital role in shaping the future of manufacturing.