The Significance of Bar Polishing Machines in Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, the role of specialized machinery cannot be overstated. Among these, bar polishing machines stand out for their functional benefits and contributions to the production process. These machines are essential in enhancing the surface quality of metal bars, providing advantages that impact both aesthetic appeal and functional integrity.

The Significance of Bar Polishing Machines in Modern Manufacturing

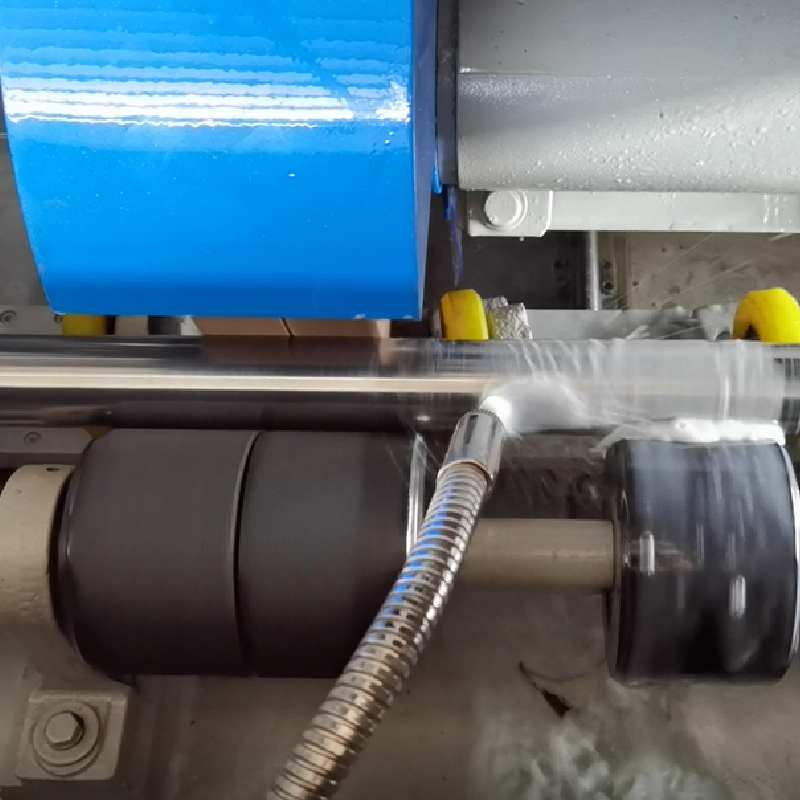

The techniques employed in bar polishing machines have advanced significantly in recent years. Modern machines utilize a combination of abrasive materials and innovative polishing technologies, such as belt polishing, brush polishing, and even automated robotic systems. These advancements ensure that manufacturers can achieve a consistent and high-quality finish on a variety of materials, whether stainless steel, aluminum, or other alloys. Furthermore, the automated features of newer polishing machines contribute to higher productivity rates, allowing for larger volumes of production without sacrificing quality.

bar polishing machine products

Another critical aspect of bar polishing machines is their adaptability. Different bars require different polishing approaches based on material and intended use. Manufacturers can choose from a wide range of configurations, including different belt speeds, types of polishing compounds, and even customizable settings to suit specific needs. This versatility makes bar polishing machines invaluable for small-scale operations and large manufacturing plants alike.

In addition to improving product quality, bar polishing machines also contribute to operational efficiency. The use of automated polishing systems significantly reduces manual labor and increases safety on the production floor. Workers are less exposed to harmful substances associated with traditional polishing methods while maintaining high standards of productivity. Consequently, manufacturers can allocate human resources to other critical areas of production, further enhancing operational flow.

Sustainability is becoming an increasingly important factor in manufacturing, and bar polishing machines can play a role in this transition. By creating polished surfaces that resist wear and corrosion, these machines can help extend the lifespan of components, reducing waste and the need for frequent replacements. Additionally, many modern machines are designed to minimize energy consumption and utilize eco-friendly polishing materials, aligning with green manufacturing initiatives.

In conclusion, bar polishing machines are vital to the manufacturing sector, providing essential benefits that range from improved product quality to enhanced operational efficiency. As technology continues to advance, these machines will likely become even more integral to the production process, enabling manufacturers to meet the growing demands of their industries while maintaining high standards of quality and sustainability. Investing in state-of-the-art bar polishing technology can ultimately lead to a competitive edge in a crowded marketplace.