The Benefits of Automatic Stainless Steel Polishing Machine Services

In industries ranging from automotive to culinary, stainless steel is a preferred material due to its durability, resistance to corrosion, and aesthetic appeal. However, for stainless steel to maintain its luster and functionality over time, it often requires polished and refined surfaces. This is where automatic stainless steel polishing machine services come into play. These automated solutions not only enhance the appearance of stainless steel products but also deliver significant advantages in terms of efficiency, consistency, and cost-effectiveness.

The Importance of Polishing Stainless Steel

Stainless steel polishing is crucial for several reasons. First and foremost, polishing improves the surface finish of the material, enhancing its shine and making it more visually appealing. This is particularly important in industries such as food processing and hospitality, where aesthetics play a key role in consumer perceptions.

Moreover, polished stainless steel surfaces are easier to clean and maintain. The smooth finish created by polishing reduces the chances of bacteria and grime adhering to the surface, thus improving hygiene and safety in environments like commercial kitchens or medical facilities. Additionally, polished stainless steel is less susceptible to rust and corrosion, extending the lifespan of the products and reducing the need for replacements.

The Role of Automatic Polishing Machines

The advent of automatic stainless steel polishing machines marks a significant advancement in how manufacturers approach surface finishing. Traditionally, polishing was a manual, labor-intensive task that often yielded inconsistent results due to human error. Automatic machines, on the other hand, provide a level of precision and repeatability that is difficult to achieve manually.

These machines utilize advanced technology such as CNC (Computer Numerical Control) programming, which allows operators to set specific polishing parameters for different materials and products. This ensures that every unit is treated uniformly, resulting in a consistent finish across large batches. Furthermore, automatic machines can operate at high speeds while maintaining quality, significantly increasing production efficiency.

Cost-Effectiveness

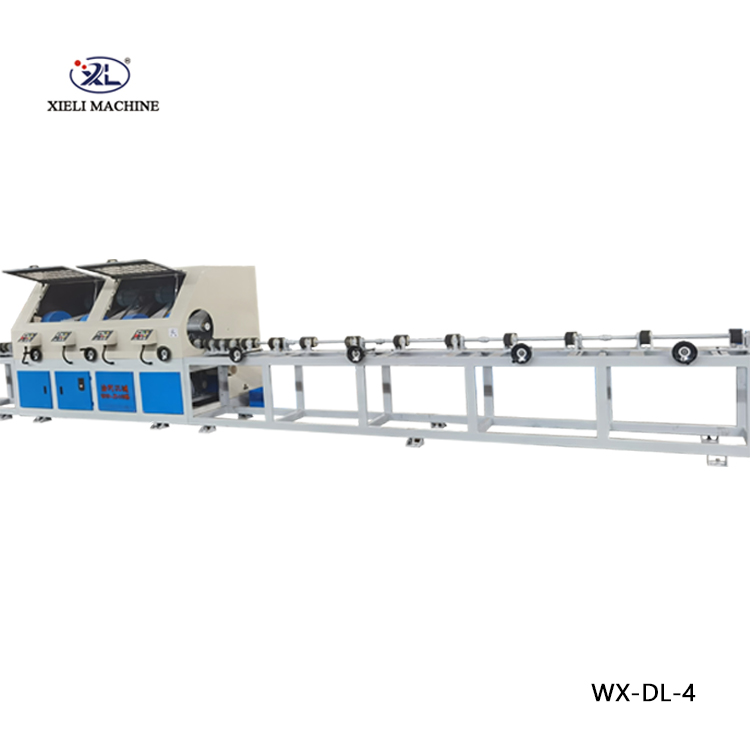

automatic stainless steel polishing machine service

Investing in automatic polishing machine services is often a game-changer for businesses. While the initial capital requirement for these machines may be substantial, the long-term savings they generate are undeniable. By streamlining the polishing process, businesses can reduce labor costs, decrease downtime, and ultimately increase output.

Moreover, the efficiency of these machines can lead to less waste. In manual polishing, material can easily be wasted due to mistakes or over-polishing. Automated systems minimize this risk, ensuring that materials are used effectively and leading to a reduction in overall production costs.

Customization and Flexibility

Another significant advantage of automatic polishing machine services is their ability to be customized based on the specific needs of different industries or particular products. This flexibility allows manufacturers to polish a wide range of shapes and sizes, from small components used in electronic devices to larger pieces incorporated into architectural designs.

Additionally, as manufacturing demands evolve, automatic machines can be reprogrammed or adjusted to suit new polishing requirements. This adaptability makes them a valuable asset for companies looking to stay competitive in a rapidly changing market.

Conclusion

The evolution of automatic stainless steel polishing machine services is transforming surface finishing in various industries. By enhancing aesthetic appeal, improving hygiene standards, and increasing efficiency and cost-effectiveness, these machines are helping businesses meet and exceed the growing demands of consumers.

Investing in these advanced polishing solutions not only elevates the quality of stainless steel products but also contributes to the overall operational excellence of manufacturing processes. As industries increasingly lean towards automation, companies that embrace automatic polishing machines will likely find themselves at the forefront of innovation, quality, and customer satisfaction in the competitive landscape of stainless steel production.