Understanding Automatic Polishing Machines A Comprehensive Overview of Manufacturers and Products

In today's manufacturing landscape, automatic polishing machines have become essential tools for enhancing the surface finish of various materials, including metals, plastics, and ceramics. With the increasing demand for precision and efficiency in production processes, manufacturers are continually innovating to provide advanced polishing solutions. This article delves into the world of automatic polishing machine manufacturers and their products, exploring the technology behind these machines and their applications across different industries.

The Importance of Automatic Polishing Machines

Automatic polishing machines streamline the finishing process, significantly reducing labor costs and improving product quality. These machines perform consistent and repeatable polishing tasks, minimizing the chances of human error. They are designed to handle a variety of materials with different hardness levels, making them versatile tools in any manufacturing setup. Whether for automotive parts, aerospace components, or consumer goods, the uniformity and shine provided by automatic polishing machines elevate the final product's value.

Key Features of Automatic Polishing Machines

Modern automatic polishing machines come equipped with advanced features tailored to meet the diverse needs of manufacturers

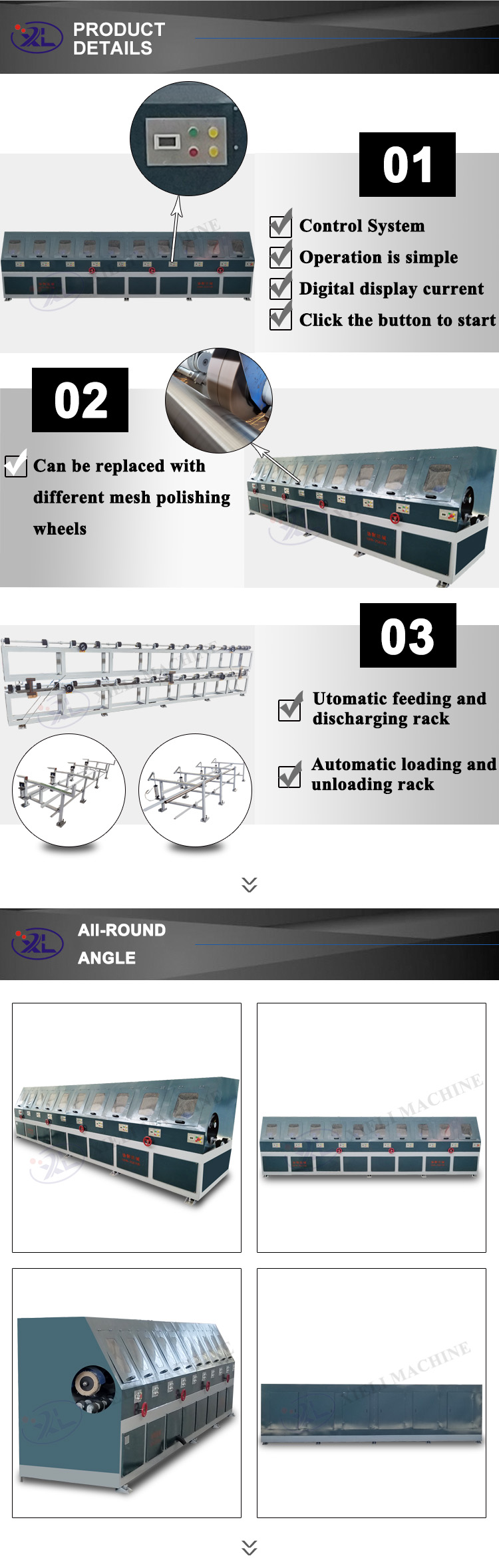

1. Programmable Controls Most automatic polishing machines have programmable interfaces that allow operators to set specific polishing parameters, such as speed, pressure, and polishing time. This programmability helps achieve a desired finish consistently across batches.

2. Multi-Station Options Some models feature multiple polishing stations, enabling simultaneous processing of various parts. This increases throughput and efficiency, making large-scale production more feasible.

3. Robotic Integration Integration with robotic systems allows for automated loading and unloading, which enhances operational efficiency. Such systems can detect and adjust to the varying shapes and sizes of parts, ensuring optimal polishing results.

4. Dust and Debris Extraction High-quality machines are often equipped with dust collection systems that maintain a clean working environment and prolong the life of the polishing materials.

5. User-Friendly Interfaces Contemporary machines offer touchscreen controls and easy-to-navigate software, simplifying the operation process and reducing the training time for operators.

Leading Manufacturers in the Automatic Polishing Machine Industry

Several noteworthy companies dominate the automatic polishing machine market, each offering unique products that cater to various industry needs. Among them are

automatic polishing machine manufacturers product

2. Glebar Company Specializing in precision grinding and polishing, Glebar's automatic machines are known for their reliability and effectiveness in achieving precise finishes on complex shapes.

3. Arati Engineering This company offers a range of automatic polishing solutions designed for metal parts, with an emphasis on durability and ease of use. Their machines are particularly popular in the automotive and aerospace sectors.

4. Buehler As a leader in materials preparation, Buehler’s automatic polishing machines are designed to meet the needs of laboratory and production environments alike, providing consistent results for metallographic applications.

5. Timesavers With a strong presence in the metalworking industry, Timesavers delivers innovative surface finishing solutions that combine speed and efficiency, ensuring high-quality polishing outcomes.

Applications Across Industries

Automatic polishing machines find applications in a variety of sectors

- Automotive Industry In the automotive sector, these machines are used to polish components like wheels, trims, and engine parts to achieve a high-end finish that enhances aesthetics and durability.

- Aerospace Aerospace manufacturers utilize polishing machines for intricate parts that require precise finishes to meet stringent safety and performance standards.

- Jewelry and Watchmaking The jewelry industry relies on polishing machines to give fine jewelry pieces a brilliant luster, ensuring that every item meets rigorous quality standards.

- Electronics Polishing in the electronics sector is crucial for components requiring smooth surfaces for better conductivity and longevity.

Conclusion

Automatic polishing machines are an invaluable addition to modern manufacturing, offering efficient, high-quality finishing solutions across numerous industries. As technology continues to advance, we can expect even more innovative features and capabilities in these machines, driving further improvements in productivity and quality. For manufacturers looking to enhance their polishing processes, partnering with leading manufacturers in the field ensures access to the best products and services for their specific needs.