The Role of Automatic Polishing Machine Manufacturers in Modern Industry

In today's fast-paced manufacturing landscape, the demand for high-quality finishing processes has led to the rise of automatic polishing machines. These sophisticated devices play a crucial role in enhancing the surface finish of various products across multiple industries, including automotive, aerospace, electronics, and jewelry. Automatic polishing machine manufacturers are at the forefront of this technological evolution, providing innovative solutions and competitive pricing that cater to the diverse needs of their clients.

Understanding Automatic Polishing Machines

Automatic polishing machines are designed to deliver consistent finishing results, significantly reducing the manual labor involved in the polishing process. Unlike traditional manual polishing methods, automatic machines employ advanced engineering, robotics, and precision controls to achieve a uniform finish. These machines can handle a wide range of materials, including metals, plastics, and composites, making them versatile tools in any production environment.

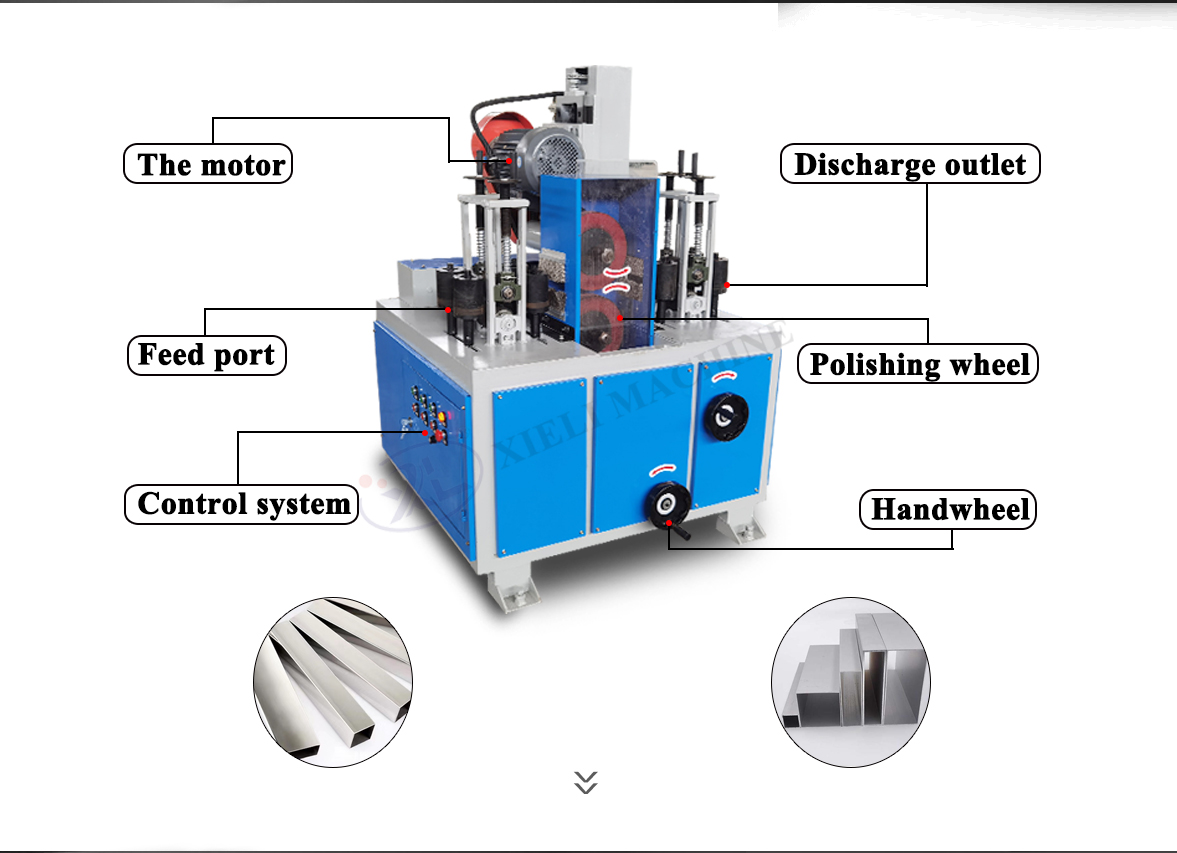

The main components of an automatic polishing machine typically include a conveyor system, polishing heads, and control systems that allow operators to adjust parameters such as speed, pressure, and polishing compounds. This level of automation not only enhances efficiency but also improves product quality, reduces waste, and minimizes the risk of human error.

The Impact of Manufacturers on Pricing

The market for automatic polishing machines is diverse, with numerous manufacturers specializing in various models and configurations

. One significant aspect of this industry is the variation in pricing, which can be influenced by several factors1. Technology and Innovation Manufacturers investing in cutting-edge technology are often able to command higher prices due to the advanced features and capabilities of their machines. Features such as programmable polishing cycles, AI-based monitoring systems, and IoT connectivity can significantly enhance productivity and efficiency, justifying the investment.

2. Customization Options Many manufacturers offer customized solutions tailored to specific industry requirements. Machines designed for particular applications, such as precision polishing for aerospace components or high-volume polishing for consumer goods, often come with a higher price tag due to the specialized engineering involved.

automatic polishing machine manufacturers pricelist

3. Material and Build Quality The materials used in the construction of polishing machines can greatly influence their cost. High-quality materials that ensure durability and longevity will naturally increase the price. Customers looking for long-term investments often prefer machines built to withstand rigorous production demands.

4. Brand Reputation Established manufacturers with a proven track record of reliability and customer service may set higher prices based on their reputation. Clients often choose brands that offer robust after-sales support and warranty services, which can impact their purchasing decisions.

5. Market Competition The level of competition within the industry can also affect pricing models. In a saturated market, manufacturers may lower prices to attract customers, while in niche markets, prices may remain high due to limited options.

Selecting the Right Manufacturer

When looking for an automatic polishing machine, it’s essential for businesses to conduct thorough research. Factors to consider include

- Device Specifications Ensure that the machine meets specific technical requirements for the intended application. - Cost-effectiveness Evaluate not just the initial purchase price but also the total cost of ownership, including maintenance, energy consumption, and operational efficiency. - Support Services Consider manufacturers that offer comprehensive customer support, including installation, training, and maintenance services. - User Reviews Look into customer testimonials and case studies to gauge the reliability and performance of the machines offered.

Conclusion

Automatic polishing machine manufacturers play a vital role in modern manufacturing by providing essential tools that enhance product quality and efficiency. Understanding the factors that influence pricing can help businesses make informed decisions when investing in polishing technology. As industries continue to evolve, the demand for innovative manufacturing solutions will likely drive further advancements in automatic polishing equipment, solidifying its place as a cornerstone of industrial excellence. By partnering with the right manufacturer, organizations can ensure they remain competitive in an ever-changing marketplace.