The Evolution of Automatic Pipe Polishing Machines A New Era in Metalworking

In the ever-evolving landscape of manufacturing and metalworking, the demand for high-quality finishes on metal components has propelled the development of sophisticated tools and machines. One such innovation is the automatic pipe polishing machine, a game-changer for industries that rely on polished pipes for various applications, from automotive to aerospace and beyond.

Understanding Automatic Pipe Polishing Machines

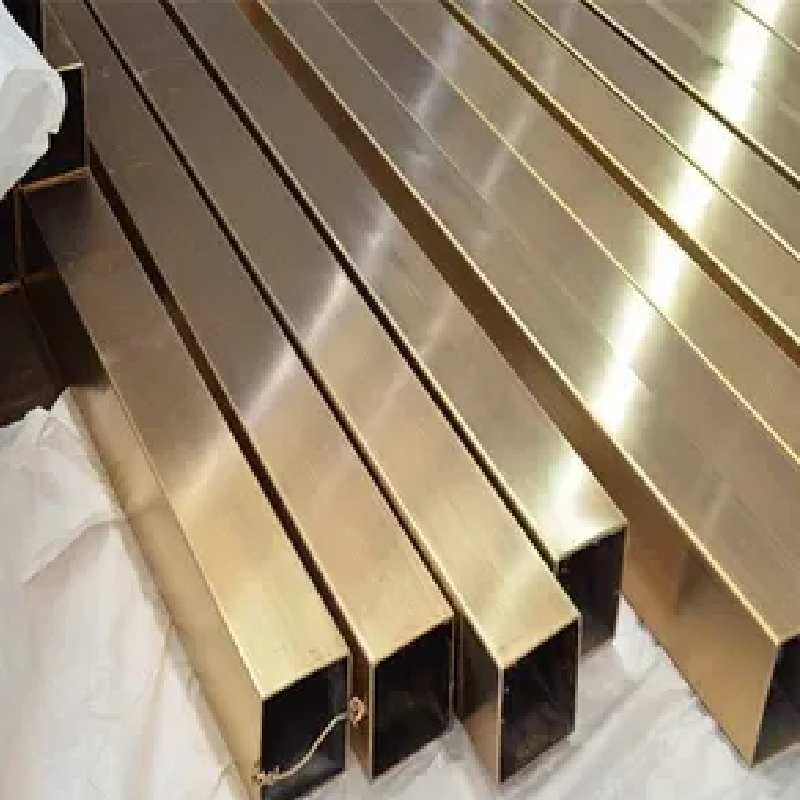

An automatic pipe polishing machine is designed to enhance the surface finish of pipes made from various metals, including stainless steel, aluminum, and carbon steel. These machines utilize advanced technology to perform polishing processes automatically, ensuring consistent quality and efficiency. The primary goal of these machines is to eliminate surface imperfections, enhance aesthetic appeal, and improve resistance to corrosion and wear.

The functioning of these machines typically involves a series of abrasive materials and polishing compounds that are applied to the pipe's surface. The automatic features allow for precise control over polishing parameters, such as speed, pressure, and duration, leading to a uniform finish while minimizing human error.

The Advantages of Automation

The integration of automation into pipe polishing offers numerous benefits. Firstly, it significantly enhances productivity. Automatic polishing machines can operate continuously and handle large volumes of work, drastically reducing the time needed to produce polished pipes compared to manual polishing methods. This capability is crucial in industries where time is of the essence, such as the manufacturing of components for car engines or other critical systems.

Secondly, the quality of the finish achieved by automatic machines is superior. With consistent settings and parameters, these machines can produce a uniform polish across multiple pipes, eliminating variations that may arise from manual techniques. This level of quality assurance is vital, as it can directly influence the performance and lifespan of the finished product.

automatic pipe polishing machine supplier

Supplier Considerations

When seeking suppliers for automatic pipe polishing machines, it’s important to consider several key factors. Firstly, the reputation of the supplier is crucial. Established suppliers often have a history of providing high-quality machines and support services, which can be invaluable for businesses looking to invest in new technology.

Moreover, understanding the specifications and capabilities of the machines offered is essential. Different industries may require specific polishing techniques and finishes, so suppliers that provide customizable solutions can be more beneficial. It’s also wise to choose suppliers that offer comprehensive after-sales support, including maintenance services and training.

Innovations in Pipe Polishing Technology

The continuous advancement in technology promises exciting developments for automatic pipe polishing machines. Features such as digital controls, IoT integration, and machine learning algorithms are being incorporated to optimize performance and enhance user experience. These innovations allow for real-time monitoring and adjustments, further improving efficiency and output quality.

Conclusion

The emergence of automatic pipe polishing machines represents a significant leap forward in metalworking technology. By streamlining production processes and ensuring high-quality finishes, these machines are helping industries meet growing demands while maintaining standards. As a result, investing in automatic pipe polishing machines from reputable suppliers can not only enhance product output but also elevate the overall quality and competitiveness of a manufacturing business. As industries continue to evolve, embracing such technologies will be crucial for sustained success and innovation.