Exploring the Benefits of Automatic Pipe Polishing Machines

In the fast-paced manufacturing sector, efficiency and quality are paramount. One innovation that has significantly enhanced productivity in metalworking is the automatic pipe polishing machine. These machines have transformed traditional polishing methods, offering numerous advantages that can lead to greater operational success.

How They Work

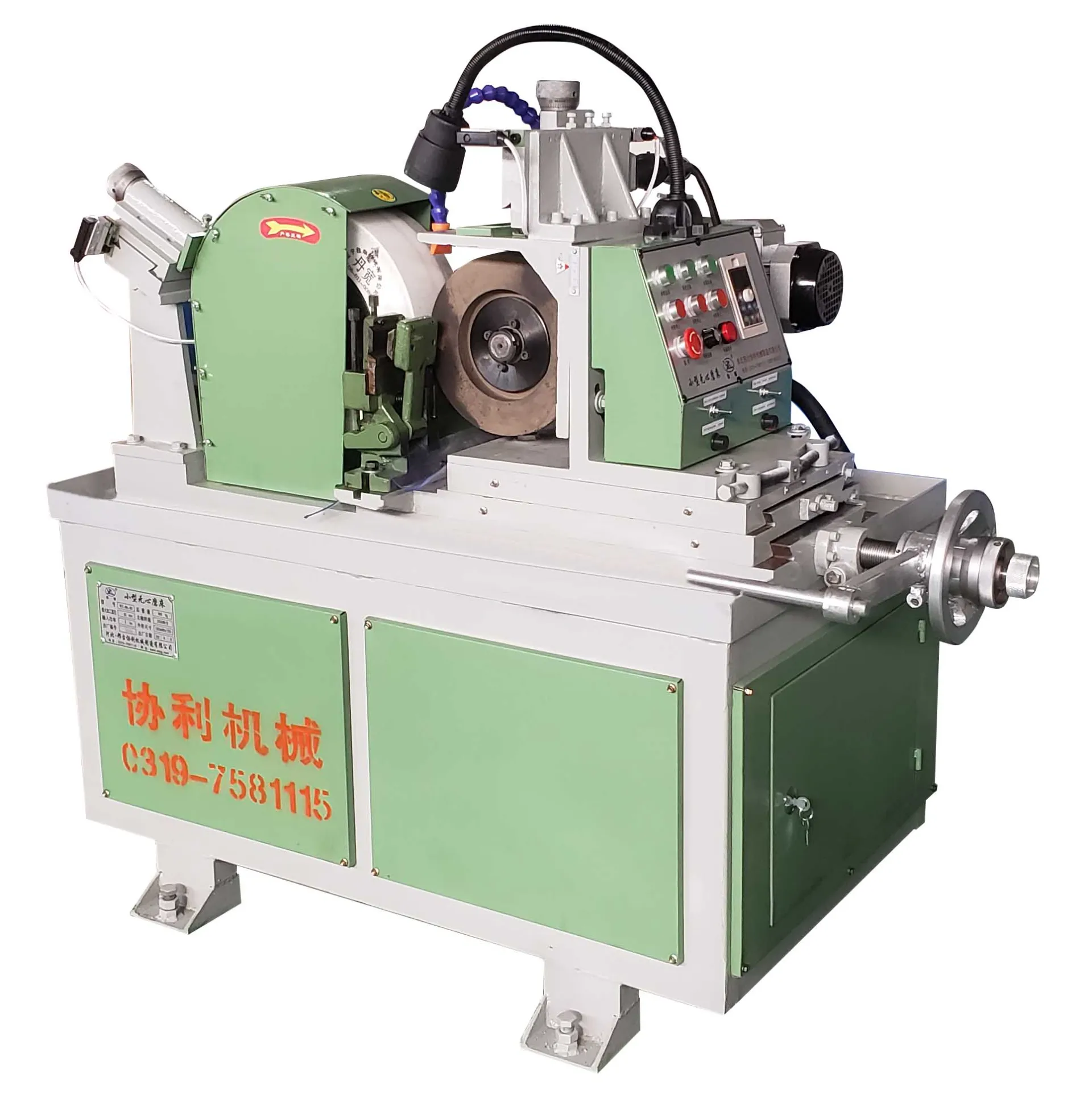

Automatic pipe polishing machines utilize advanced technology to smooth and polish metal pipes with precision. By incorporating automated systems, these machines can adjust their operational parameters in real-time, ensuring a consistent finish across multiple pieces. Typically, they employ abrasive materials that are strategically applied to the surface of the pipes, effectively removing imperfections and imparting a high-quality sheen.

Benefits of Implementation

1. Enhanced Productivity One of the primary advantages of using automatic pipe polishing machines is the significant boost in productivity. These machines operate faster than manual polishing methods, allowing manufacturers to process larger volumes of pipes in less time. This efficiency can lead to shorter lead times and increased output, catering to rising market demands.

2. Consistency in Quality Automatic polishing machines excel at delivering uniform results. This consistency is essential for industries where precision matters, such as aerospace and automotive manufacturing. With traditional polishing methods, human error can lead to varying surface finishes, but automatic systems ensure every pipe meets quality standards.

automatic pipe polishing machine quotes

3. Reduced Labor Costs Automating the polishing process can significantly cut down on labor costs. Fewer operators are needed to maintain the machines, allowing businesses to allocate human resources to more complex tasks. Additionally, by reducing the risk of injuries associated with manual polishing, companies can further lower their expenses related to worker safety.

4. Versatility These machines can be designed to accommodate different pipe sizes and materials, making them highly versatile. Manufacturers can invest in a single machine capable of handling various projects, thus maximizing their return on investment. This adaptability is crucial in industries that require frequent changes in production demands.

5. Environmental Benefits Many modern automatic polishing machines use environmentally friendly materials and processes. By minimizing waste and reducing the amount of harmful emissions associated with traditional polishing, these machines can contribute to a more sustainable manufacturing environment.

6. Ease of Operation Today’s automatic pipe polishing machines are user-friendly, often featuring intuitive control panels and software that allows operators to set parameters with ease. This simplicity means that even less experienced workers can efficiently operate the machines, reducing the learning curve and speeding up the training process.

Conclusion

In conclusion, automatic pipe polishing machines represent a crucial advancement in the metalworking industry. Their ability to enhance productivity, maintain consistent quality, reduce labor costs, and provide versatility makes them an indispensable tool for modern manufacturers. As industries continue to evolve, the adoption of such innovative machinery will likely become even more prevalent, paving the way for smarter, more efficient production processes. Investing in automatic pipe polishing technology not only improves operational efficiency but also positions businesses to compete effectively in today's demanding marketplace.