The Rise of Automatic Pipe Polishing Machine Manufacturers

In an era where technology drives innovation across various industries, automatic pipe polishing machines have emerged as essential tools for manufacturers. The demand for these machines is steadily growing, thanks to their efficiency, precision, and ability to meet the high standards of modern production processes. This article explores the significance of automatic pipe polishing machine manufacturers, their contributions to the industry, and the key features that set successful machines apart.

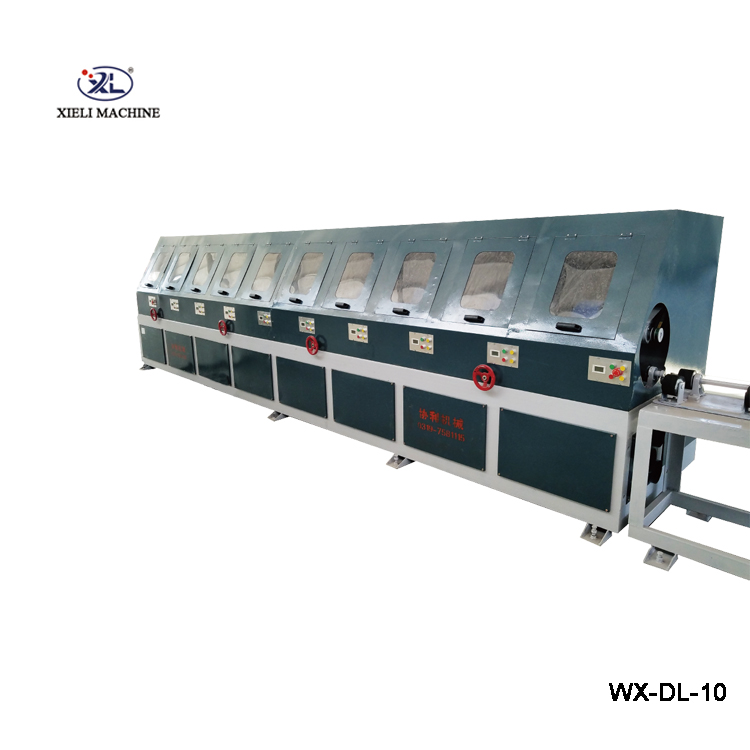

Understanding Automatic Pipe Polishing Machines

Automatic pipe polishing machines are designed to streamline the finishing process of pipes made from various materials, including stainless steel, aluminum, and others. These machines play a critical role in the manufacturing of pipes used in multiple applications, from construction and automotive to aerospace and plumbing.

The primary function of these machines is to enhance the surface finish of pipes, ensuring they are free from imperfections, scratches, and other visual blemishes. This is crucial not only for aesthetic reasons but also for improving the corrosion resistance and longevity of the pipes. As industries increasingly prioritize quality and performance, automatic polishing machines deliver a solution that meets these heightened expectations.

The Role of Manufacturers in the Industry

Manufacturers of automatic pipe polishing machines are vital enablers of the production processes in various sectors. They invest in research and development to innovate and improve their existing products. By integrating advanced technologies such as robotics and automation, these manufacturers increase productivity and reduce the labor intensity associated with traditional polishing methods.

Furthermore, they provide custom solutions tailored to the specific needs of their clients. This adaptability is a key selling point for many manufacturers, as pipe specifications can vary significantly across different applications. Manufacturers often collaborate closely with their clients to ensure that the machines are designed to handle the particular dimensions and materials of the pipes being polished.

Key Features of Automatic Pipe Polishing Machines

When evaluating automatic pipe polishing machines, several features set high-quality machines apart from the rest

.automatic pipe polishing machine manufacturers

1. Automation and Control Systems Modern machines often come equipped with sophisticated control systems that allow for easy programming and monitoring. Users can set parameters for the polishing process, ensuring consistent results across large production runs.

2. Versatility The ability to polish pipes of varying diameters and materials is another critical feature. Manufacturers that offer machines capable of handling diverse applications will likely see higher demand from a broader range of industries.

3. Efficiency Time is money in manufacturing. Efficient machines can complete the polishing process faster without sacrificing quality. Features like adjustable speed settings and automated loading/unloading systems contribute to reduced cycle times.

4. Safety Features Given the nature of polishing operations, safety is paramount. High-quality machines are designed with built-in safety features to protect operators, such as emergency stop buttons, safety guards, and automatic shut-off mechanisms.

5. Maintenance and Support Reliable manufacturers offer robust customer support and maintenance services. An easily maintainable machine not only ensures longevity but also enhances productivity by minimizing downtime.

Looking Towards the Future

The future of automatic pipe polishing machine manufacturers looks promising as the global demand for quality finishing processes continues to rise. The increasing shift towards Industry 4.0, marked by the integration of automation and data exchange in manufacturing technologies, indicates that manufacturers who embrace smart manufacturing will be at the forefront of this industry.

Emerging trends such as the development of environmentally friendly polishing solutions and the incorporation of artificial intelligence for predictive maintenance further highlight the evolution of this sector. As manufacturers continue to innovate and enhance the functionality of their machines, they will play a crucial role in shaping the future of pipe manufacturing.

Conclusion

In conclusion, automatic pipe polishing machine manufacturers are foundational to the modern manufacturing landscape. Their commitment to innovation, quality, and customer satisfaction ensures that industries can produce pipes that meet stringent standards. As technology advances and the market evolves, these manufacturers will undoubtedly remain pivotal players, driving efficiency and excellence in the pipe polishing process. The synergy of advanced machinery and skilled manufacturers will continue to push industry boundaries, ensuring that products not only meet the demands of today but are also prepared for the challenges of tomorrow.