The Evolution of Automatic Centerless Grinding Machines

In today's fast-paced manufacturing environment, precision and efficiency are paramount. Among the various machining processes, centerless grinding stands out as a preferred choice for producing high-quality cylindrical components. The advent of automatic centerless grinding machines has dramatically transformed this process, making it more efficient and reliable.

Understanding Centerless Grinding

Centerless grinding is a process that involves the grinding of external surfaces of cylindrical parts without requiring any axial support. The workpiece is placed in the machine between two wheels a grinding wheel and a regulating wheel. The grinding wheel performs the removal of material, while the regulating wheel controls the rotation and axial positioning of the workpiece. This mechanism allows for continuous grinding, which significantly enhances productivity.

Advancements in Technology

With advancements in technology, automatic centerless grinding machines have integrated sophisticated features that improve their operational capabilities. Modern machines come equipped with computer numerical control (CNC) systems. This automation allows for precise adjustments in parameters such as wheel speed, feed rate, and grinding depth, enhancing the overall quality of the finished product.

Moreover, the use of AI and machine learning algorithms in these machines helps in predicting maintenance needs and optimizing performance. This predictive approach minimizes downtime, increases productivity, and ensures that the machines operate at peak efficiency.

Benefits of Automatic Centerless Grinding Machines

1. Increased Productivity Automatic centerless grinding machines are designed for high-speed operations. The ability to maintain continuous grinding cycles reduces the time taken for each production batch, enabling manufacturers to meet tight deadlines and high demand.

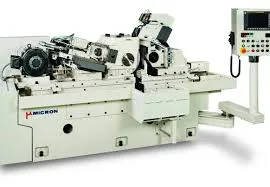

automatic centerless grinding machine product

2. Consistent Quality The precision and consistency offered by automatic machines lead to uniformity in product quality. Automated adjustments ensure that the specifications of each part are met accurately, reducing the likelihood of defects.

3. Labor Efficiency With automation, the need for manual intervention is minimized. Operators can monitor multiple machines simultaneously, allowing for better resource allocation and reducing labor costs.

4. Versatility Modern automatic centerless grinders can accommodate a wide range of materials and sizes. They can be adjusted for different production runs without significant downtime, making them suitable for both large-scale manufacturing and custom jobs.

5. Enhanced Safety Features Automation reduces the risk associated with manual operations. Automatic machines come with various safety features, including emergency stop buttons, protective enclosures, and monitoring systems that alert operators to potential hazards.

The Future of Automatic Centerless Grinding Machines

As industries evolve, so too will the capabilities of automatic centerless grinding machines. Future advancements may include greater integration with IoT technology, allowing machines to communicate with one another and with central control systems. This connectivity will enable manufacturers to streamline their operations further, making data-driven decisions for continuous improvement.

Additionally, the emphasis on sustainability and energy efficiency will drive the development of machines designed to minimize resource consumption. Manufacturers are increasingly looking for ways to reduce their environmental impact, and the grinding industry is no exception.

Conclusion

Automatic centerless grinding machines are at the forefront of manufacturing technology, offering significant improvements in efficiency, quality, and safety. As these machines continue to evolve, they promise to further enhance production capabilities across various industries. For manufacturers looking to stay competitive in a rapidly changing marketplace, investing in automatic centerless grinding technology is not just an option; it is a necessity that will define their success in the years to come. Embracing this technology will not only boost manufacturing processes but also contribute to a more sustainable and efficient industrial future.