Understanding the Price List of Automatic Centerless Grinding Machines

In the modern manufacturing landscape, efficiency, precision, and automation are paramount in maintaining competitive advantage. Centerless grinding machines have emerged as essential tools for processing cylindrical parts with a high degree of accuracy and minimal human intervention. Among the various types of grinding machines, automatic centerless grinding machines are becoming increasingly popular due to their ability to enhance productivity significantly. However, before investing in such machines, understanding their price structure is vital for businesses eager to optimize their manufacturing processes.

What is Automatic Centerless Grinding?

Centerless grinding is a machining process that involves the grinding of a workpiece without the need for holding it in place. This is achieved by using two wheels a grinding wheel and a regulating wheel, which work in tandem to push and rotate the workpiece. The automatic variant of this process incorporates advanced technology, including CNC (Computer Numerical Control) systems, which increase precision and allow for greater automation. This technology can minimize the chances of errors and reduce labor costs, making it a favorable option for many businesses.

Factors Influencing the Price of Automatic Centerless Grinding Machines

1. Machine Specifications The specifications of the grinding machine play a significant role in determining its price. Machines designed for high production volumes may have more advanced features, such as higher speeds, larger work capacities, and enhanced cooling systems, and as a result, will be priced higher.

2. Brand Reputation Established brands with a strong reputation for quality and reliability often charge a premium for their machines. It's crucial to weigh the reliability of cheaper alternatives against the potential costs of downtime and maintenance associated with less-known brands.

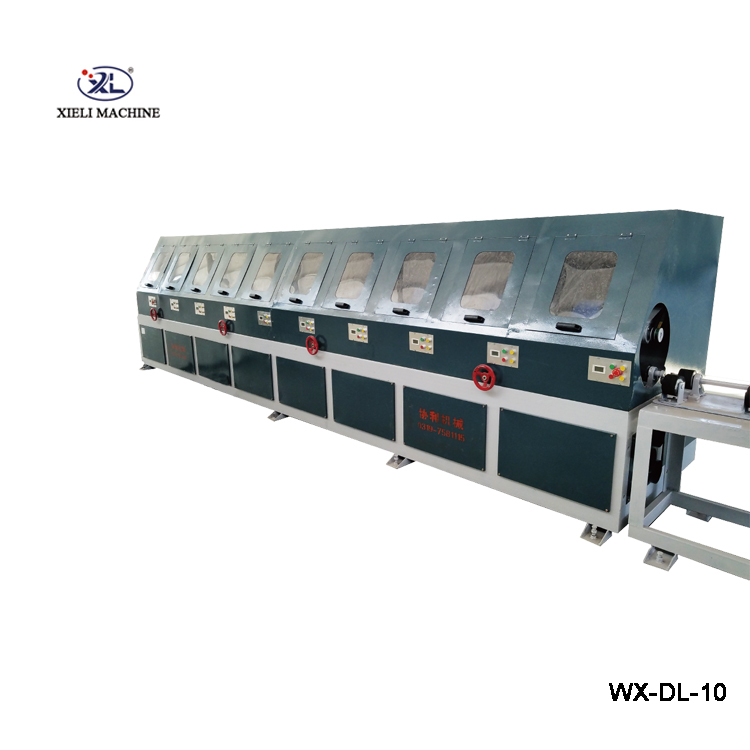

automatic centerless grinding machine pricelist

3. Automation Level The extent of automation integrated into the machine is a significant factor affecting pricing. Fully automated machines that require minimal human intervention command higher prices than semi-automated or manual versions.

4. Customization Options Many manufacturers offer customization options for their automatic centerless grinding machines. Custom features that enhance productivity or adapt the machine to specific production processes can significantly affect the price.

5. After-Sales Support The quality and extent of after-sales support and maintenance services can also factor into pricing. Machines that come with robust support packages tend to be more expensive, but they may ultimately save costs through enhanced efficiency and minimized downtime.

Average Price Range

Typically, automatic centerless grinding machines can range from $30,000 to over $100,000. Entry-level machines may be available at the lower end of the price spectrum, while high-end models with advanced features and capabilities are positioned at the upper end. It is essential for businesses to conduct thorough market research and compare different models and prices to ensure they are making an informed decision.

Conclusion

Investment in an automatic centerless grinding machine can deliver remarkable benefits in terms of efficiency, productivity, and precision. However, understanding the price list and the factors that influence machine prices is crucial for making an informed investment decision. Businesses must consider their production needs, budget constraints, and the long-term value generated by the equipment. By carefully evaluating these aspects, manufacturers can select the right machine that not only meets their production requirements but also contributes positively to their bottom line in the competitive manufacturing industry. As technology continues to evolve, staying informed about the latest advancements and pricing structures will be essential for any business aiming to thrive in today’s market.