AS9100 Certified Centerless Grinder Companies Ensuring Precision and Quality in Aerospace Manufacturing

In the competitive landscape of aerospace manufacturing, maintaining high standards of quality and precision is non-negotiable. AS9100 certification, a widely recognized quality management standard specifically designed for the aerospace industry, plays a crucial role in ensuring that manufacturers meet the rigorous demands of this sector. Centerless grinder companies that achieve AS9100 certification demonstrate their commitment to excellence, precision, and continuous improvement, which are vital in producing aerospace components.

Understanding AS9100 Certification

AS9100 is a standard developed by the International Aerospace Quality Group (IAQG), which outlines stringent requirements for a quality management system. This certification not only focuses on meeting regulatory requirements but also emphasizes enhancing customer satisfaction through effective process application, risk management, and continual improvement. Companies in the aerospace sector, including those that specialize in centerless grinding, need to comply with these standards to ensure the safety and reliability of their products.

The Importance of Centerless Grinding in Aerospace

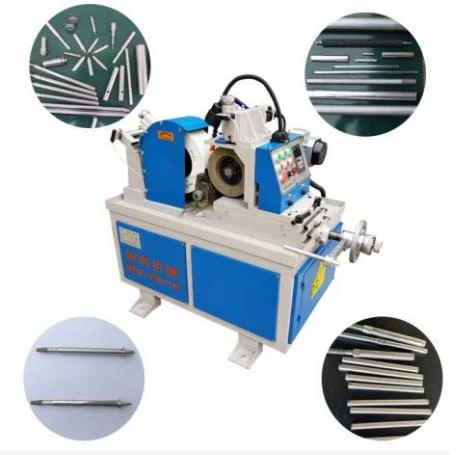

Centerless grinding is a precision machining process that plays a critical role in the manufacture of aerospace components. This method allows for the high-volume production of cylindrical parts with exceptional surface finishes and tight tolerances. The process eliminates the need for a fixture, which not only reduces setup time but also increases efficiency, making it ideal for the fast-paced aerospace industry.

Centerless grinders are utilized for various applications within aerospace manufacturing, including the production of shafts, rollers, and other intricate components. The ability to maintain consistent dimensions and surface quality is essential, as even the smallest imperfections can have significant implications for safety and performance in aerospace applications.

as9100 centerless grinder company

Benefits of AS9100 Certification for Centerless Grinder Companies

For centerless grinder companies, achieving AS9100 certification offers numerous advantages. Firstly, it enhances their credibility within the aerospace industry. Customers can be confident that certified companies adhere to rigorous quality standards, which is paramount when entrusting them with critical aerospace components.

Secondly, AS9100 certification fosters a culture of continuous improvement. Companies are encouraged to regularly review and refine their processes, leading to increased efficiency and reduced waste. This commitment to improvement not only benefits the organization but also translates into better products and services for customers.

Additionally, AS9100 certification helps centerless grinder companies better manage risks associated with their operations. By implementing systematic processes for identifying and mitigating potential issues, these companies can reduce operational disruptions and enhance their overall reliability. In an industry where failure is not an option, this proactive approach is invaluable.

Conclusion

In conclusion, AS9100 certified centerless grinder companies are crucial players in the aerospace manufacturing sector. Their adherence to rigorous quality management standards ensures that they deliver precision-engineered components that meet the highest safety and performance criteria. As the aerospace industry continues to evolve, the importance of such certifications cannot be overstated. By investing in quality management and continuous improvement, these companies not only enhance their reputation but also contribute to the overall safety and reliability of aerospace operations.

As manufacturers seek reliable partners in their supply chains, the role of AS9100 certified centerless grinder companies will become even more prominent. By maintaining high standards of quality, these organizations help drive innovation and success in the dynamic world of aerospace manufacturing.