CE Certification for Aluminium Tube Polishing Machines Ensuring Quality and Safety in Production

In the contemporary manufacturing landscape, the importance of quality assurance and adherence to safety standards cannot be overstated. This is particularly true in the realm of machinery used for processing materials such as aluminium. One area that has seen significant advancements is the development of aluminium tube polishing machines, which play a crucial role in the finishing processes of various industries. A key factor that elevates the status of these machines is the attainment of CE certification, which symbolizes compliance with European health, safety, and environmental protection standards.

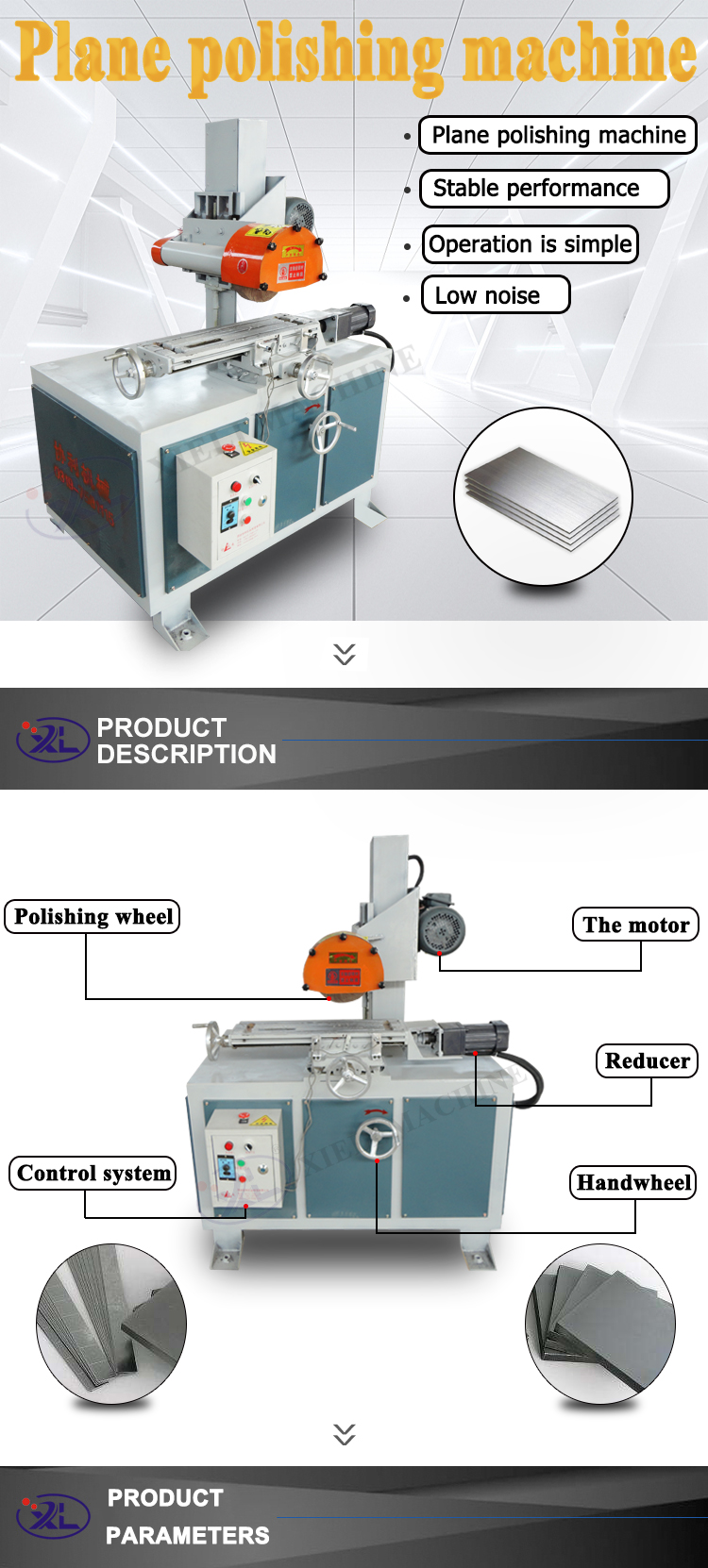

Aluminium is a lightweight, corrosion-resistant, and versatile material that is widely used across sectors that range from automotive to aerospace and construction. Polishing machines designed for aluminium tubes are essential for enhancing the aesthetic appeal and functional properties of the finished product. These machines are designed to remove imperfections, rough edges, and oxidation from the surface of aluminium tubes, resulting in a smooth and shiny finish that meets stringent industry requirements.

CE certification is a crucial element for manufacturers of aluminium tube polishing machines, as it signifies that the equipment conforms to European Union (EU) regulations. The CE marking indicates that the product has undergone rigorous testing and meets the necessary safety and performance standards, thereby assuring customers of its reliability and effectiveness. This certification is particularly important for companies looking to penetrate European markets, as it is often a prerequisite for sales and distribution within the region.

The process of obtaining CE certification involves several key steps. Manufacturers must conduct a thorough assessment of their machines, ensuring they comply with relevant directives such as the Machinery Directive (2006/42/EC) and the Low Voltage Directive (2014/35/EU). This assessment includes evaluating the design, manufacturing processes, and operational safety features of the machine. Additionally, a risk assessment must be carried out to identify potential hazards associated with the equipment and implement necessary mitigation measures.

ce certification aluminium tube polishing machine

Once the assessment is complete, manufacturers are required to compile technical documentation that demonstrates conformity. This documentation serves as proof that the machine has been designed and manufactured following the EU's regulatory framework. Subsequently, the manufacturer must affix the CE marking to their product, signifying compliance and allowing it to be marketed within the European Economic Area (EEA).

The benefits of having CE certification for aluminium tube polishing machines extend beyond regulatory compliance

. It enhances the machine’s reputation in the marketplace, instills confidence in potential buyers, and can lead to increased sales. Furthermore, CE certification fosters a culture of quality and safety within the manufacturing process, benefiting both the producers and their customers.In addition to meeting safety and quality standards, CE-certified aluminium tube polishing machines often feature advanced technologies that enhance productivity and efficiency. These machines may incorporate automated systems, smart controls, and advanced polishing techniques that reduce waste and energy consumption, aligning with the current trends of sustainability and eco-friendliness.

In conclusion, CE certification is an essential aspect of aluminium tube polishing machines, serving as a testament to their safety, quality, and efficacy. As industries continue to evolve, the demand for high-quality finishing solutions will only grow, making it imperative for manufacturers to prioritize compliance with international standards. By investing in CE-certified equipment, businesses can ensure they remain competitive in the global market while promoting safety and sustainability in their manufacturing processes.