The Importance of Stainless Steel Pipe Polishing Machines

In various industries, particularly in the fields of manufacturing, automotive, and construction, stainless steel is a favored material due to its corrosion resistance, durability, and aesthetic appeal. However, to maximize these properties, the finishing process—specifically polishing—plays a crucial role. This is where stainless steel pipe polishing machines come into play.

Understanding Stainless Steel Pipe Polishing

Polishing stainless steel pipes involves removing imperfections and enhancing the surface finish. This process not only improves the material's aesthetics, making it shinier and more visually appealing, but it also ensures that the stainless steel retains its functional prowess. A well-polished surface is less prone to harboring dirt and bacteria, making it essential for applications in food processing, pharmaceuticals, and medical equipment.

The polishing process typically involves several steps, including grinding, buffing, and polishing, with each step utilizing different abrasives and techniques to achieve the desired finish. Stainless steel pipe polishing machines automate this process, leading to more consistent results and reduced labor costs.

Types of Stainless Steel Pipe Polishing Machines

There are various types of polishing machines that cater to different requirements

1. Manual Polishers While labor-intensive, manual polishers allow for detailed work on smaller batches or intricate designs. They are often preferred for custom projects that require a high level of craftsmanship.

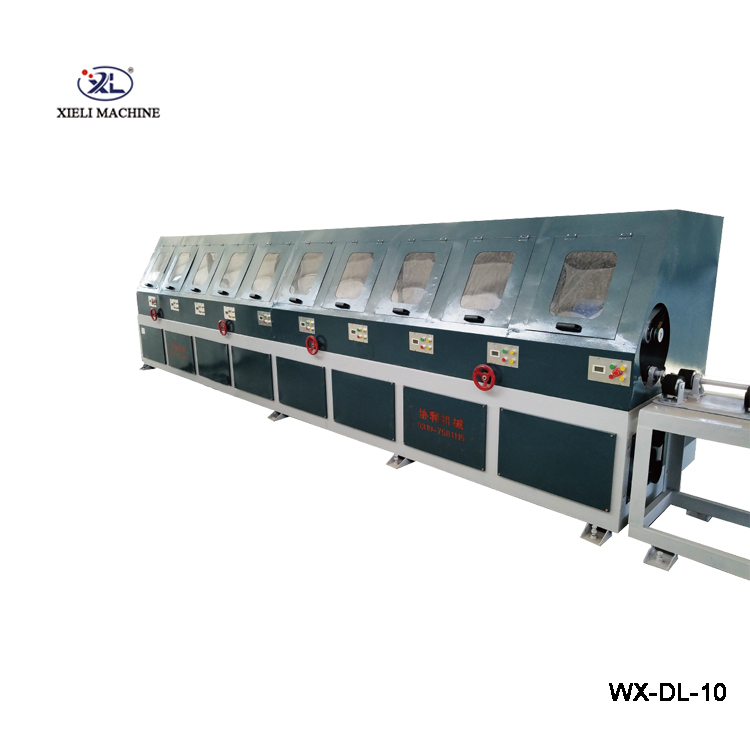

2. Automatic Polishers These machines are designed for high-volume production. They automate the polishing process, reducing human error and increasing efficiency. Automatic polishing machines are ideal for operations where consistency is crucial.

stainless steel pipe polishing machine quotes

3. CNC Polishers CNC (Computer Numerical Control) polishing machines utilize advanced software to control the polishing process. This technology allows for precise and repeatable polishing of complex shapes, making it invaluable in industries where precision is critical.

4. Orbital Polishers These machines use a circular motion to polish surfaces, ensuring even coverage and minimizing the risk of surface damage. They are commonly used for achieving a high-gloss finish on stainless steel pipes.

Selecting the Right Machine

Choosing the suitable stainless steel pipe polishing machine depends on various factors including production volume, the complexity of the pipes, and the desired finish. Businesses must assess their specific needs and evaluate different machines based on their specifications, including speed, power consumption, and ease of use.

In addition to the polishing machines themselves, businesses should also consider the quality of polishing materials such as abrasives, compounds, and buffing wheels. The correct combination is vital for achieving optimal surface finishes.

The Economic Impact of Polishing Machines

Investing in stainless steel pipe polishing machines can lead to significant cost savings in the long run. While the initial investment may seem substantial, the increased efficiency, reduced labor costs, and improved product quality often result in a quick return on investment. Additionally, polished stainless steel products can demand higher prices in the market, increasing profitability.

In conclusion, stainless steel pipe polishing machines are indispensable tools in various industries. They not only enhance the aesthetic quality and functional performance of stainless steel pipes but also contribute to the overall efficiency and profitability of manufacturing operations. As industries evolve, the demand for high-quality finishes on stainless steel products is unlikely to diminish, making these machines a valuable asset for any business involved in metal fabrication. Investing in the right polishing technology is an investment in future success.