Centerless Grinder Price Quotes A Comprehensive Overview

When considering the purchase of a centerless grinder, one of the most pressing factors for businesses and individual buyers alike is the price. Centerless grinding is widely used in various industries, including automotive, aerospace, and manufacturing, due to its efficiency and ability to achieve precise tolerances. Therefore, understanding the factors influencing price quotes is essential for making an informed decision.

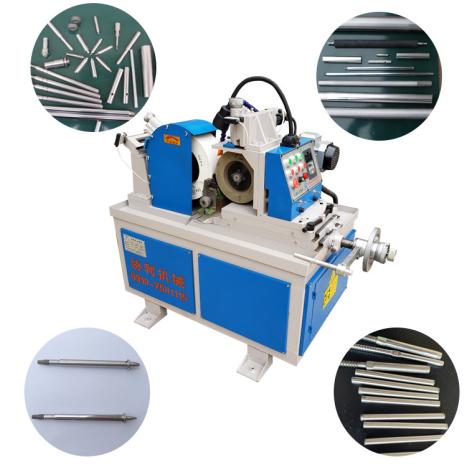

Understanding Centerless Grinders

Centerless grinders are designed to grind cylindrical parts without needing to center the workpiece. This unique feature allows for continuous production and high-volume manufacturing, making them particularly valuable in industrial processes. There are two primary types of centerless grinders infeed and through-feed. Each type serves different applications, and their pricing may vary accordingly.

Factors Influencing Price Quotes

1. Type of Centerless Grinder As mentioned, the type of grinder – infeed or through-feed – significantly impacts pricing. Through-feed grinders generally have a simpler design and might be less expensive than infeed machines, which require more advanced setups.

2. Size and Capacity The size of the grinder and its capacity to handle different workpiece dimensions directly affect the price. Larger machines, capable of processing bigger workpieces or higher volumes, tend to be more expensive due to the increased materials and engineering involved.

3. Brand and Quality Renowned brands typically charge a premium for their machines. Their reputation for reliability, advanced technology, and superior customer service often justifies the higher cost. Investing in a well-known brand may lead to better long-term performance and reduced downtime.

centerless grinder price quotes

4. Features and Specifications Advanced features such as automation, CNC (Computer Numerical Control) capabilities, and enhanced safety measures add to the cost of centerless grinders. Buyers should assess which features are essential for their operations and whether those justify the price increment.

5. New vs. Used Equipment New centerless grinders come with a higher price tag but provide the latest technology, warranties, and support services. Used grinders can be a more economical choice, though they may come with risks regarding condition and maintenance history. Careful inspection and evaluation are crucial when considering used machinery.

6. Market Demand The overall demand for manufacturing equipment can influence pricing. Fluctuations in demand can lead to variations in availability and pricing; during periods of high demand, prices may increase, while a surplus of machines may result in competitive pricing.

Getting Accurate Quotes

When seeking centerless grinder price quotes, it's advisable to contact multiple manufacturers and suppliers. Request detailed quotes that outline not only the price but also the specifications, features, and any available financing options. Additionally, inquire about warranties, servicing options, and delivery times, as these factors can significantly affect the total investment.

Conclusion

Investing in a centerless grinder is a crucial decision that can impact a business's productivity and bottom line. By understanding the various factors that influence pricing and engaging with multiple suppliers for quotes, buyers can ensure they are making a well-informed purchase. As technology in machining continues to evolve, staying updated with the latest advancements can also guide buyers towards selecting the best machine for their specific needs, ultimately maximizing their investment in the long run.