The Evolution of Surface Grinder and Centerless Grinder Manufacturing

In the realm of precision machining, the surface grinder and centerless grinder hold vital importance for achieving high-quality finishes and precise dimensions on various materials. The manufacturing technologies and factories that produce these machines have evolved significantly over the years, responding to the increasing demands of modern industries, including automotive, aerospace, and general manufacturing. This article explores the intricacies of surface grinder and centerless grinder factories, examining their advancements and the impact they have on the machining sector.

Understanding Surface Grinders and Centerless Grinders

Surface grinders are versatile machines used to produce flat surfaces on a workpiece. They work by using a rotating grinding wheel to remove material, creating a smooth and precise surface finish that is critical in applications where tolerances are essential. Centerless grinders, on the other hand, are specifically designed for grinding cylindrical parts without the need for a fixed center. This type of grinding allows continuous processing of workpieces, which enhances productivity by streamlining the operational workflow.

Technological Innovations in Manufacturing

The factory environment for producing these grinders has seen revolutionary changes, primarily driven by advancements in technology. Automation and robotics play a significant role, allowing for high-speed production and reducing human error. Automated machining lines enable manufacturers to produce surface and centerless grinders with remarkable precision and efficiency.

Additionally, the integration of computer numerical control (CNC) technology has transformed traditional grinding processes. CNC machines offer unparalleled control over machining parameters, enabling manufacturers to achieve complex shapes and intricate designs that were previously unattainable. The precision offered by CNC technology ensures that each surface grinder or centerless grinder produced meets stringent quality standards.

Materials and Design Considerations

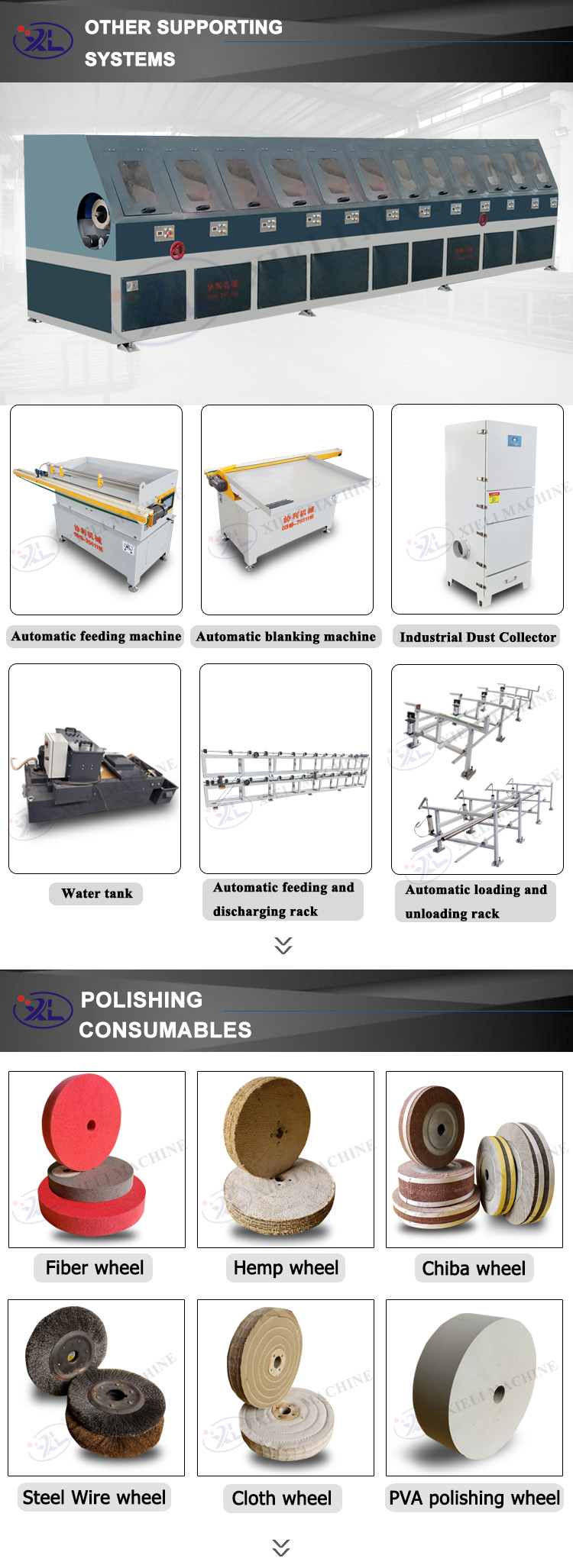

surface grinder centerless factory

The materials used in the construction of surface and centerless grinders have also evolved. Factories are increasingly utilizing high-strength alloys and composites to enhance the durability and performance of these machines. The design of grinding wheels has progressed as well, with new abrasives and bonding materials being developed to enhance grinding effectiveness and lifespan.

Furthermore, considerations such as thermal stability and vibration damping have become crucial in the design process. These factors directly impact the performance of grinding machines, affecting their ability to maintain precision during extended operations. Investing in research and development allows manufacturers to innovate continually, leading to improved designs that meet modern challenges.

Quality Assurance and Testing Protocols

In today's manufacturing landscape, quality assurance has become a non-negotiable aspect of production. Factories producing surface and centerless grinders employ comprehensive testing protocols to ensure that each machine performs reliably. Rigorous inspection techniques, including in-process measurements and final performance evaluations, guarantee that grinders operate within specified parameters.

This commitment to quality not only enhances the reputation of manufacturers but also bolsters the trust that customers place in their machines. Ultimately, a focus on superior craftsmanship and quality can lead to increased satisfaction and repeat business.

Conclusion

The realm of surface grinder and centerless grinder manufacturing is a testament to the advancements in technology, materials, and design. As industries continue to demand higher precision and efficiency, the factories that produce these vital machines will play a pivotal role in shaping the future of precision machining. Through ongoing innovation, robust quality assurance processes, and a commitment to excellence, the manufacturing of surface and centerless grinders will continue to evolve, ensuring that they meet the ever-changing needs of modern industries.