High-Quality Industrial Metal Polishing Machines Elevating Surface Finishing Standards

In the realm of industrial manufacturing, the finishing process plays a crucial role in determining the quality, aesthetics, and functionality of metal products. High-quality industrial metal polishing machines have become indispensable tools in various sectors, from automotive to aerospace, providing an efficient and effective means of achieving superior surface finishes. This article delves into the significance, features, and advancements of these machines, highlighting their essential role in modern manufacturing.

High-Quality Industrial Metal Polishing Machines Elevating Surface Finishing Standards

A key feature of high-quality industrial metal polishing machines is their versatility. These machines are equipped to handle various types of metals including stainless steel, aluminum, brass, and copper. The ability to switch between different polishing compounds and techniques is essential for manufacturers looking to achieve specific finishes, whether it be a brushed matte appearance or a mirror-like shine. Many machines offer adjustable speed settings and customizable polishing heads, allowing operators to tailor the process to the material and desired finish.

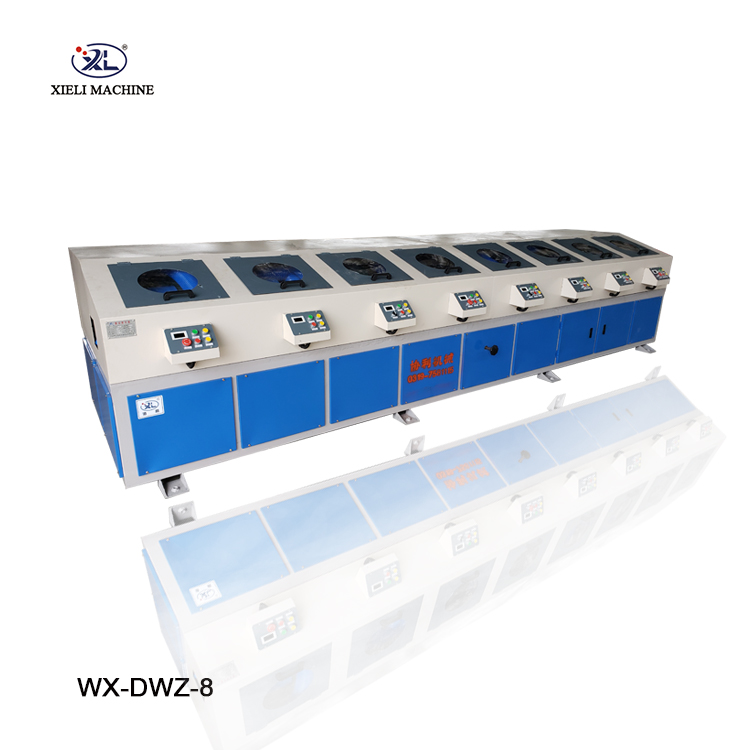

high quality industrial metal polishing machine

Another significant advantage of advanced polishing machines is their efficiency. Modern polishing equipment often employs automation technology, which minimizes human intervention and reduces the risk of error. Automation also enhances productivity, enabling manufacturers to increase output without compromising quality. For instance, CNC (Computer Numerical Control) polishing machines can execute intricate polishing patterns with precision, significantly speeding up the finishing process compared to manual methods.

Safety and ease of use are additional considerations in the design of high-quality polishing machines. Features such as ergonomic controls, dust extraction systems, and safety guards help protect operators and maintain a healthy work environment. Improved user interfaces and intuitive designs make training easier, allowing operators to become proficient in using the equipment in a shorter time frame. This focus on safety and usability is increasingly crucial as industries strive to maintain compliance with health and safety regulations.

The drive towards sustainability in manufacturing is also influencing the development of metal polishing machines. Many manufacturers are now looking for eco-friendly polishing solutions that reduce harmful emissions and waste. Innovations in polishing compounds and processes, such as water-based and biodegradable options, are gaining traction. Additionally, machine manufacturers are investing in technologies that minimize energy consumption, contributing to more sustainable manufacturing practices.

In conclusion, high-quality industrial metal polishing machines are vital assets in today's manufacturing landscape. Their ability to deliver consistent, efficient, and high-standard finishes is crucial for industries where quality cannot be compromised. As technology continues to evolve, these machines will likely incorporate advanced features that further enhance their capabilities, supporting manufacturers in their quest for excellence. Embracing these innovations not only improves the products but also aligns with sustainability goals, ultimately leading to a more responsible and efficient manufacturing ecosystem.