High-Quality Centerless Grinder Machines Revolutionizing Precision Machining

In the realm of precision machining, centerless grinder machines have emerged as a vital tool for manufacturers seeking efficiency and accuracy. These machines facilitate the grinding process by allowing for the continuous rotation of the workpiece, providing exceptional benefits that elevate production standards across various industries. As the demand for high-quality components continues to rise, investing in high-quality centerless grinder machines is becoming increasingly essential.

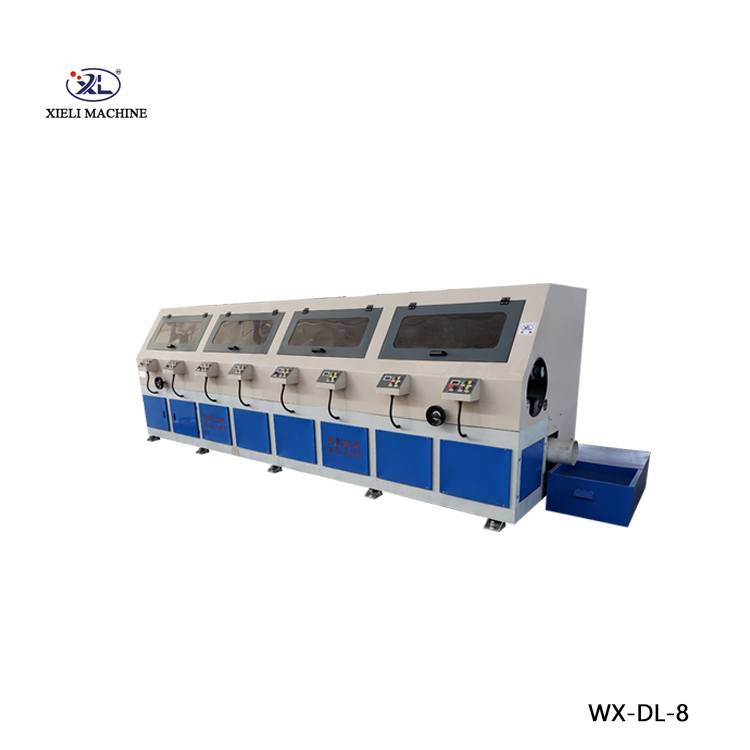

Centerless grinding differs fundamentally from conventional grinding processes. While traditional methods often rely on rigid fixtures to hold workpieces stationary, centerless grinding employs two wheels – a grinding wheel and a regulating wheel – to rotate the workpiece freely. This unique setup not only promotes faster machining cycles but also enhances precision, enabling manufacturers to achieve tight tolerances that are often required in automotive, aerospace, medical, and electronic applications.

One of the hallmarks of high-quality centerless grinder machines is their ability to produce parts with minimal human intervention. Automation is a crucial aspect of modern manufacturing, and advanced centerless grinders are designed with features that promote seamless integration into automated production lines. This not only increases throughput but also contributes to a reduction in labor costs, ultimately improving the bottom line for manufacturers.

Another significant advantage offered by high-quality centerless grinder machines is their versatility

. These machines can handle a wide range of materials, including metals like steel, aluminum, and titanium, as well as plastics and composites. This adaptability makes centerless grinding an invaluable solution for manufacturers who work with diverse materials and require the capability to switch between jobs with minimal downtime.high quality centerless grinder machines

Precision is of paramount importance in machining, and high-quality centerless grinder machines excel in this area. Equipped with state-of-the-art technology, such as digital readouts and computer numerical control (CNC), these machines can achieve tolerances as close as 0.0001 inches. The consistency and uniformity of the parts produced by centerless grinding are unparalleled, leading to enhanced product quality and customer satisfaction.

The durability and reliability of high-quality centerless grinder machines are also noteworthy. Built with robust materials and advanced engineering, these machines are designed to withstand the rigors of continuous operation. This longevity not only minimizes the need for frequent maintenance but also ensures that manufacturers can rely on their equipment for sustained production.

Moreover, with the increasing emphasis on sustainability and environmentally friendly practices, many modern centerless grinder machines are engineered to minimize waste and energy consumption. Advanced features, such as regenerative drives and closed-loop systems, allow for greater efficiency and reduced environmental impact, aligning with the evolving standards of responsible manufacturing.

In conclusion, the benefits of investing in high-quality centerless grinder machines are manifold. From enhanced precision and efficiency to versatility and sustainability, these machines are integral to the success of contemporary manufacturing operations. As the industry continues to evolve, those who embrace the capabilities of centerless grinding will position themselves at the forefront of innovation, driving growth and delivering exceptional quality to their customers. For businesses looking to enhance their machining processes, high-quality centerless grinder machines represent not just a tool, but a competitive edge in a fast-paced market.