Centerless Bar Grinding Machine Revolutionizing Precision Machining

In the ever-evolving landscape of manufacturing, the precision and efficiency of machining processes play a crucial role in determining the quality of the final product. One pivotal machine in this domain is the centerless bar grinding machine, renowned for its capacity to deliver exceptional surface finishes and tight tolerances on cylindrical parts. This article will delve into the features, advantages, and applications of centerless bar grinding machines.

Features of Centerless Bar Grinding Machines

Centerless bar grinding machines are designed to facilitate the grinding of cylindrical workpieces without the need for centering, which significantly enhances productivity. The primary components include a grinding wheel, a regulating wheel, and a workpiece support platform. The machine operates on a basic principle the workpiece is positioned between the grinding wheel and the regulating wheel, which rotates at a controlled speed. This setup allows for continuous, unobstructed grinding and precise dimensional control.

One of the standout features of these machines is their ability to handle a variety of materials, including metals, plastics, and composites. They are equipped with advanced controls that ensure consistent grinding parameters, resulting in uniformity across batches. Additionally, many modern centerless grinding machines come with automation capabilities, further streamlining the production process.

Advantages of Centerless Grinding

The benefits of using a centerless bar grinding machine are manifold. Firstly, the elimination of a fixed center enhances throughput by allowing for rapid loading and unloading of workpieces. This capability makes centerless grinding particularly suitable for high-volume production environments. Secondly, the process minimizes the need for secondary operations, such as re-chucking, which further reduces cycle times and enhances efficiency.

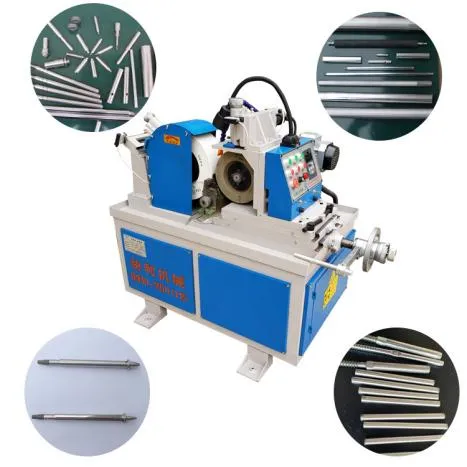

centerless bar grinding machine product

In terms of precision, centerless grinding machines excel at achieving tight tolerance levels, often within a few micro-meters. This level of accuracy is essential for industries such as aerospace, automotive, and medical, where the integrity of components is critical. Furthermore, these machines provide superior surface finishes, which can significantly impact the performance characteristics of the final products.

Applications Across Industries

Centerless bar grinding machines find diverse applications across various industries. In the automotive sector, they are commonly used for grinding components such as shafts, rods, and pins, where precision is paramount. The aerospace industry also benefits from centerless grinding, utilizing it for parts that require stringent tolerances and surface finishes, such as landing gear components and engine parts.

Moreover, the medical industry relies on centerless grinding for manufacturing surgical instruments and implants, where quality and precision are non-negotiable. The versatility of these machines allows them to adapt to the specific requirements of different sectors, accommodating various sizes and shapes of workpieces.

Conclusion

In conclusion, centerless bar grinding machines are a pivotal technology in the precision machining industry. Their unique design allows for high-speed, efficient grinding of cylindrical components while maintaining exceptional accuracy and surface quality. With applications spanning multiple sectors, the importance of these machines cannot be overstated. As manufacturing processes continue to evolve, the innovation and improvements in centerless grinding technology will undoubtedly play a crucial role in meeting the increasing demands for precision and productivity in today’s competitive landscape.