Exploring Acme Centerless Grinder Products Precision and Efficiency in Manufacturing

In the world of manufacturing, precision is paramount. Industries that rely on high-level accuracy and efficiency in their production processes turn to specialized machinery to achieve their goals. One such essential piece of equipment is the centerless grinder. Acme is a brand that stands out in this arena, known for its high-quality centerless grinder products that cater to various industrial needs.

Understanding Centerless Grinding

Before delving into Acme’s offerings, it’s crucial to understand what centerless grinding entails. Unlike traditional grinding processes where the workpiece is supported by a fixed structure, centerless grinding positions the workpiece between two grinding wheels. The wheels rotate in the same direction, but one wheel is stationary while the other is mobile. This setup allows for the continuous feed and quick processing of components without the need for complex fixtures.

Centerless grinding is heralded for its ability to produce extremely precise cuts and finishes, making it ideal for producing small to medium-sized parts. Industries that frequently utilize this technology include automotive, aerospace, medical, and manufacturing sectors—where high tolerances and consistent results are critical.

Acme’s Centerless Grinder Products

Acme has carved a niche for itself by offering a range of centerless grinders that prioritize both versatility and performance

. Their products cater to a variety of applications, showcasing the adaptability of their designs.1. Acme 191 Series The 191 series is particularly popular for its combination of tilt-head grinding and programmable controls. This enables operators to achieve fine adjustments on the fly, boosting productivity. The 191 series is ideal for high-volume production runs where speed and accuracy are essential.

2. Acme 250 Series For those looking for a balance between manual and automated processes, the 250 series provides a solution. It is designed for manufacturers who require flexibility in their operations. The 250 series allows for both automatic and semi-automatic cycle options, making it easier to switch between configurations depending on project demands.

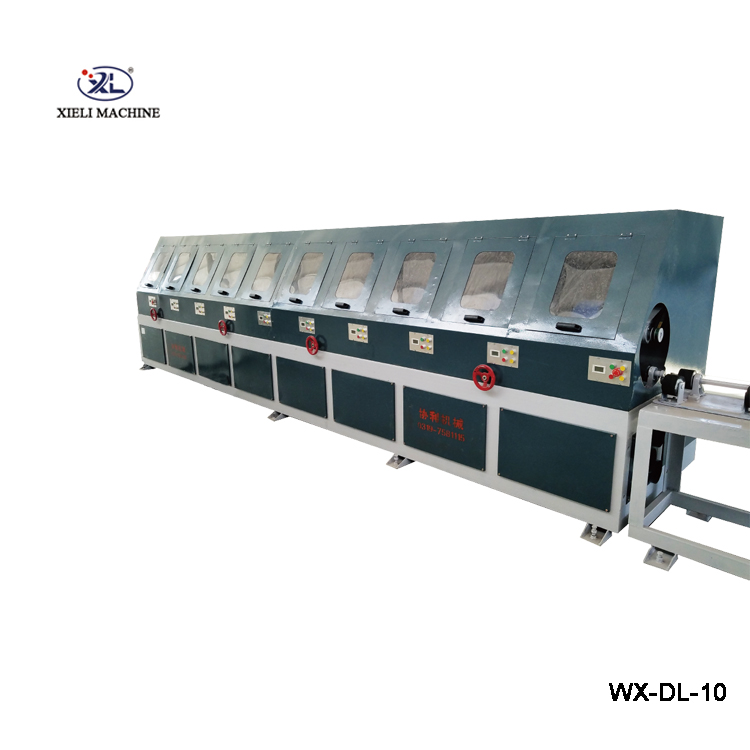

acme centerless grinder products

3. Acme Ultra Series The Ultra series takes precision to the next level, featuring advanced control systems and robust build quality. This line is suitable for industries that deal with tight tolerances and specialized materials, such as titanium and high-strength alloys. The Ultra series boasts quick changeover capabilities, reducing downtime and significantly enhancing production efficiency.

4. Acme Loader and Unloader Systems Acme doesn’t just produce centerless grinders; they also offer automated loader and unloader systems to streamline the manufacturing process. These systems minimize manual intervention, reducing the risk of errors and further increasing throughput.

Innovative Technologies

Acme's centerless grinders incorporate the latest technological advancements to ensure top-notch performance. For instance, their adaptive control systems can instantly adjust to grinding variables, optimizing the process in real-time. Additionally, these machines are designed with user-friendly interfaces allowing operators to easily monitor and manage operations without extensive training.

Moreover, the emphasis on durability and maintenance means that companies investing in Acme grinders can expect longevity and a lower total cost of ownership. The machines undergo rigorous testing to ensure they can handle the demands of continuous operation while maintaining accuracy.

Customer Support and Services

Acme’s commitment to customer satisfaction extends beyond the sale of its grinders. They provide comprehensive support services, including installation, training, and maintenance services, ensuring that users can maximize their equipment's potential. This level of service is invaluable for businesses trying to minimize operational downtime and maintain production efficiency.

Conclusion

Acme’s centerless grinder products have earned their reputation for providing manufacturers with reliable, precise, and efficient solutions for their grinding needs. With a diverse product line designed to accommodate various applications and an unwavering commitment to quality and customer support, Acme stands as a leader in the centerless grinding market. As industries continue to demand higher precision and efficiency, investing in Acme’s advanced technology will undoubtedly provide companies with a competitive edge in a rapidly evolving landscape.