The Acme Centerless Grinder Factory Precision Engineering at Its Best

In the realm of precision engineering, the Acme Centerless Grinder Factory stands as a hallmark of excellence and innovation. Specializing in the production of centerless grinding machines, Acme has carved a niche for itself in the manufacturing industry, providing top-notch equipment that meets the stringent demands of various sectors, including automotive, aerospace, and medical industries.

The Importance of Centerless Grinding

Centerless grinding is a manufacturing process that is essential for producing high-precision components with superior surface finishes. Unlike traditional grinding processes, centerless grinding does not require the part to be mounted between centers. Instead, it utilizes a specialized setup involving a grinding wheel and a regulating wheel to maintain the part's position throughout the grinding operation. This method allows for high throughput and efficiency, making it a preferred choice for mass production of cylindrical parts.

At Acme, we understand that accuracy and consistency are of utmost importance. Our centerless grinders are engineered to deliver precision down to the micron level. This capability is critical in industries where even the smallest deviation can lead to significant issues in performance and safety.

Advanced Technology and Innovation

What sets the Acme Centerless Grinder Factory apart from its competitors is our unwavering commitment to innovation. Our research and development team continuously explores new technologies and methodologies to improve grinding processes. We utilize advanced software for simulation and modeling, enhancing the design of our machines and optimizing their performance.

Moreover, we integrate cutting-edge features such as automatic in-feed systems, precision controls, and real-time monitoring capabilities into our grinders. This technological edge allows our customers to achieve higher productivity, reduced downtime, and ultimately, a better return on investment.

Quality Assurance

Quality assurance is a cornerstone of our manufacturing philosophy. At Acme, we adhere to the highest standards in production, from the selection of raw materials to the final testing of our machines. Each centerless grinder undergoes rigorous quality checks, ensuring that it meets our customers' exact specifications and industry regulations.

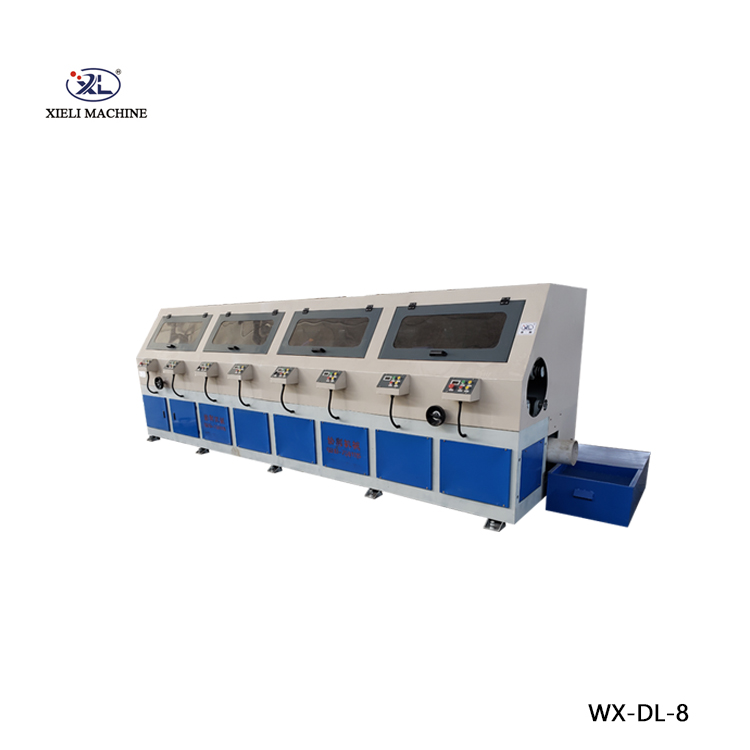

acme centerless grinder factory

Our dedicated quality control team employs a comprehensive set of inspection tools and processes to evaluate each machine's performance. This commitment to quality not only enhances the durability and reliability of our equipment but also guarantees that our customers can operate with confidence.

Customer-Centric Approach

At Acme, we believe that our customers’ success is intrinsically linked to our own. Therefore, we maintain a customer-centric approach in all our operations. From the initial consultation to post-sales support, we prioritize understanding our clients’ unique needs and providing tailored solutions.

Our experienced sales team works closely with customers to identify their specific requirements, recommending the most suitable centerless grinding machines for their applications. Additionally, our support team is always available to assist with training, maintenance, and troubleshooting, ensuring a seamless experience for our clients.

Sustainability Initiatives

In response to the growing environmental concerns in the manufacturing sector, Acme is also committed to sustainable practices. We continuously strive to reduce our carbon footprint by implementing energy-efficient technologies and optimizing our manufacturing processes. Our machines are designed to consume less energy while delivering exceptional performance, helping our customers lower their operational costs and environmental impact.

Conclusion

The Acme Centerless Grinder Factory embodies the pinnacle of precision engineering through innovation, quality, and customer service. As industries continue to evolve, the demand for high-quality, efficient grinding solutions will only increase. Acme remains dedicated to meeting this demand by providing cutting-edge centerless grinders that empower manufacturers to achieve their production goals with unmatched accuracy and efficiency.

In a world where precision matters, choosing Acme means investing in reliability and performance. We invite you to explore our range of centerless grinding solutions and experience the Acme difference for yourself. Our machines are not just tools; they are a commitment to excellence in manufacturing.