Exploring the Benefits of ACME Centerless Belt Grinders

In the world of manufacturing and machining, efficiency and precision are paramount. One machine that embodies these qualities is the ACME Centerless Belt Grinder. This innovative machine offers a variety of features that can significantly enhance production capabilities in industries ranging from automotive to aerospace. Below, we will explore the advantages of using ACME Centerless Belt Grinders and how they can transform your operations.

What is a Centerless Belt Grinder?

Centerless belt grinding is a process that involves grinding without the need for a fixed location for the workpiece, which allows for a continuous production flow. Unlike traditional grinding methods that require extensive setup time and fixturing, centerless grinding offers unparalleled efficiency. The ACME Centerless Belt Grinder utilizes a belt system to perform grinding tasks, which contributes to faster material removal rates and smoother finishes.

Key Features of ACME Centerless Belt Grinders

1. Versatile Applications ACME Centerless Belt Grinders are designed for a wide range of applications, including surface finishing, contouring, and material removal. Whether you are working with metals, plastics, or composites, these grinders can handle various materials with ease.

2. High Precision The design of the ACME grinders allows for exceptional precision. They can achieve tight tolerances, making them suitable for high-stakes applications where precision is critical. This level of accuracy is vital in sectors such as aerospace and medical device manufacturing, where even the slightest deviation can lead to significant issues.

3. Improved Efficiency One of the standout features of ACME Centerless Belt Grinders is their efficiency. The continuous feed system means that parts can be processed rapidly, reducing cycle times and increasing throughput. This efficiency translates into cost savings and improved production rates, allowing manufacturers to meet the growing demands of the market.

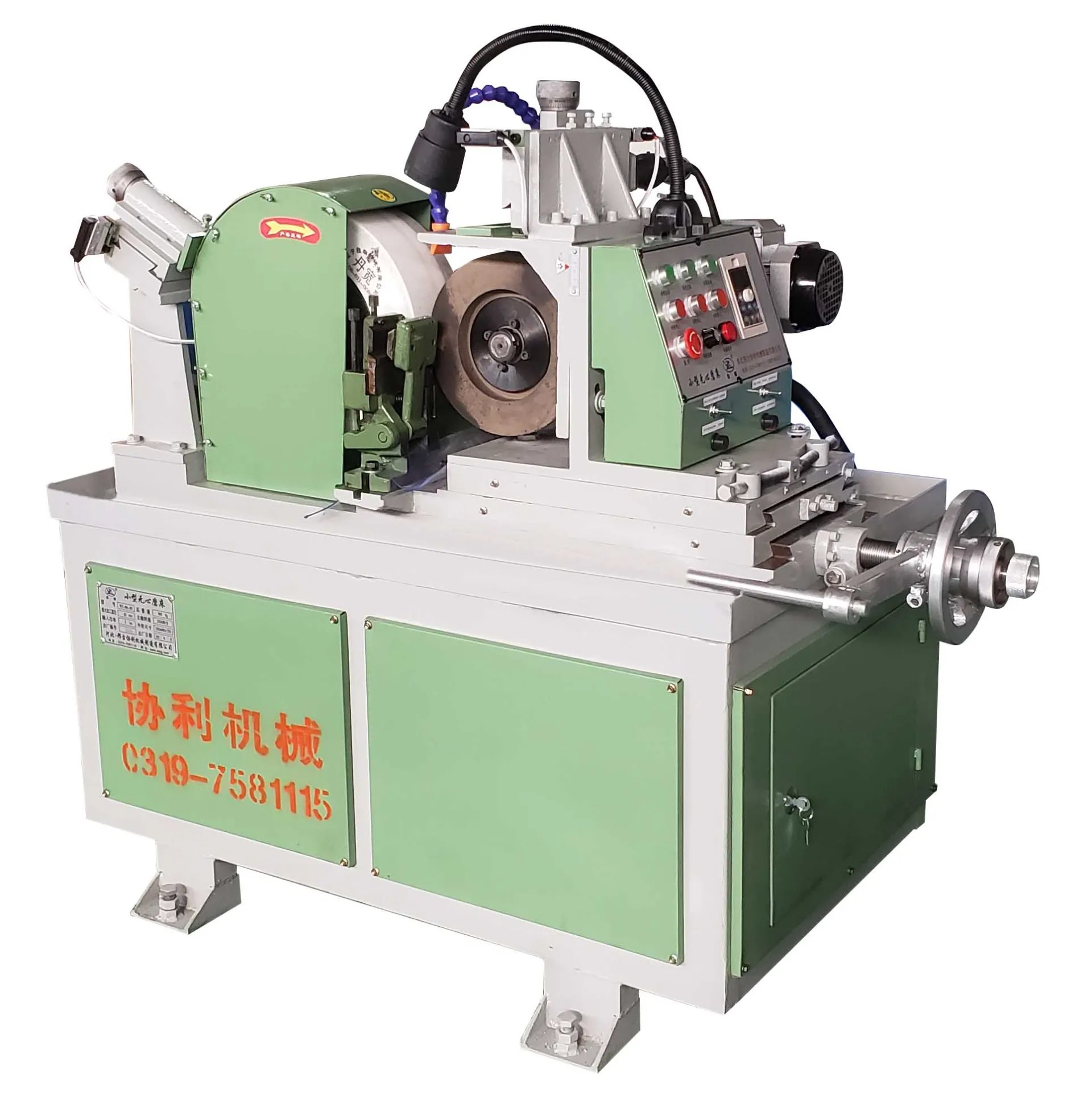

acme centerless belt grinder quotes

4. User-Friendly Interface Modern ACME machines come with intuitive controls that make operation straightforward. Operators can quickly set parameters, adjust feeding speeds, and monitor performance without extensive training. This user-friendly design reduces the learning curve and allows for more seamless integration into existing production lines.

5. Durability and Reliability ACME is renowned for its commitment to quality, and their Centerless Belt Grinders are no exception. Built with robust materials and designed to withstand the rigors of daily use, these machines promise longevity. Manufacturers can rely on them for consistent performance, reducing downtime associated with equipment failure or maintenance.

Cost-Effectiveness

Investing in an ACME Centerless Belt Grinder may require upfront capital, but the long-term benefits far outweigh the costs. The enhanced productivity, reduced waste, and improved quality control make these machines a smart investment. Additionally, their versatility means that one machine can replace multiple manual operations, streamlining processes and saving valuable shop space.

Conclusion

In conclusion, the ACME Centerless Belt Grinder represents a leap forward in grinding technology. Its combination of precision, efficiency, and user-friendliness makes it an invaluable asset for any manufacturing operation. As industries continue to evolve and competition increases, the need for effective and reliable machinery will only grow. By adopting advanced technologies like the ACME Centerless Belt Grinder, businesses can ensure they remain competitive in a fast-paced market.

Whether you are looking to improve production rates, enhance product quality, or reduce operational costs, the ACME Centerless Belt Grinder is a solution worth considering. With its myriad benefits, it's clear that investing in this technology could be a game-changer for manufacturers looking to maximize their potential.