Understanding Centerless Grindings and Their Suppliers

In the realm of precision engineering and manufacturing, centerless grinding stands out as a vital process for achieving high tolerance and smooth surface finishes on a variety of components. As industries continue to demand more precise and efficient manufacturing techniques, the role of centerless grinding and its suppliers has become increasingly important. This article delves into the nuances of centerless grinding and discusses what to consider when selecting a supplier for these specialized machines and services.

What is Centerless Grinding?

Centerless grinding is a machining process that involves removing material from a workpiece without the need for a center hole, which differentiates it from traditional cylindrical grinding. This process is mainly utilized for grinding cylindrical components and is known for its efficiency, as it allows for continuous production and the processing of multiple parts simultaneously.

The basic principle of centerless grinding involves three key components the grinding wheel, the regulating wheel, and the workpiece support. The workpiece is positioned between the grinding wheel and the regulating wheel, which controls the speed of the workpiece as it is fed through the grinding wheel. This method provides significant advantages, including increased productivity, reduced cycle times, and the ability to grind materials with high precision.

Applications of Centerless Grinding

Centerless grinding finds a broad range of applications across various industries, including automotive, aerospace, medical, and manufacturing. It is commonly used for producing precision shafts, pins, tubes, and other cylindrical parts that require fine tolerance and smooth surfaces. The process is ideal for components that may need to be produced in large quantities, such as fuel injectors, bearings, and rods.

Choosing a Centerless Grinder Supplier

When it comes to selecting a centerless grinder supplier, several factors need to be taken into consideration to ensure that the chosen partner can meet your specific requirements.

abbr for centerless grinder supplier

1. Experience and Expertise Look for suppliers with a proven track record in centerless grinding. Their experience in the industry can be a huge asset, as it indicates familiarity with various materials and part geometries.

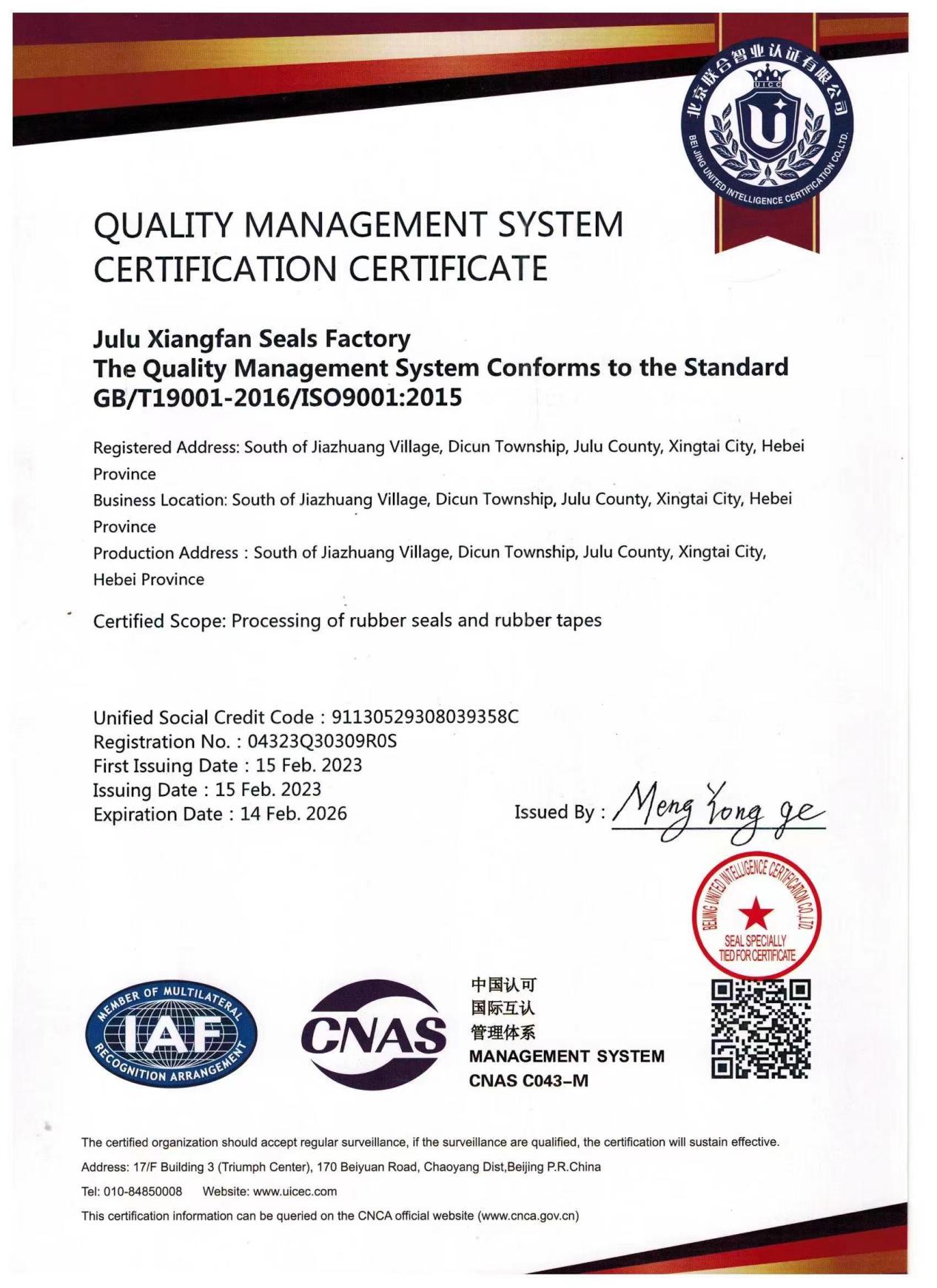

2. Quality Assurance The supplier should have robust quality assurance protocols in place, as precision is critical in centerless grinding. Certifications like ISO 9001 can indicate a commitment to quality.

3. Range of Services Some suppliers offer additional services beyond just machine supply, such as setup, training, and maintenance. This can be beneficial for companies that may not have the in-house expertise to handle these aspects.

4. Customization Capabilities Different applications may require tailored grinding solutions. A good supplier should be able to provide customization options based on your specific part requirements and tolerances.

5. Technology and Equipment It’s essential to assess the technology and equipment used by the supplier. Advanced centerless grinding machines equipped with CNC technology and automation can significantly enhance productivity and precision.

6. Customer Support and Service Efficient customer service is crucial. The supplier should offer prompt support and assistance to address any issues or questions that may arise.

7. Reputation in the Industry Researching the supplier’s reputation through reviews, testimonials, and case studies can provide insight into their reliability and trustworthiness.

Conclusion

As industries evolve, the demand for high-precision components continues to grow. Centerless grinding has become a cornerstone of modern manufacturing due to its efficiency and effectiveness. Choosing the right centerless grinder supplier is critical to achieving the desired results and maintaining competitiveness. By focusing on experience, quality, and technological capabilities, companies can find a supplier that not only meets their manufacturing needs but also contributes to their long-term success in the market.