The Landscape of 24x24 Centerless Grinder Manufacturers

In the ever-evolving world of manufacturing, precision and efficiency are paramount. Among the machinery that plays a crucial role in various industrial sectors is the centerless grinder, particularly the 24x24 centerless grinders. Used extensively for processing cylindrical workpieces, these machines offer a unique advantage by allowing for continuous grinding operations without needing to remove the part from its fixture.

Understanding Centerless Grinding

Centerless grinding is a machining process that enhances the precision of workpieces by grinding them without supporting them between centers. Instead, the workpiece is held in place by a regulating wheel and a grinding wheel. This technique is particularly beneficial for producing parts with intricate geometries and tight tolerances. The 24x24 specification indicates the size of the grinding wheel, which is vital for achieving desired outcomes in various applications.

The Importance of Manufacturers

The demand for centerless grinders has surged due to their efficiency in producing high-quality components. Several manufacturers specialize in this niche, providing a variety of models and customization options to meet the diverse needs of their clientele. Leading manufacturers invest in research and development to enhance machine performance, increasing speed, accuracy, and durability. As a result, businesses looking to acquire a 24x24 centerless grinder must be aware of the various factors that differentiate manufacturers in this competitive landscape.

Key Considerations When Choosing a Manufacturer

1. Reputation and Experience Established manufacturers often have a history of delivering quality machines that meet industry standards. It is advisable to research potential manufacturers to understand their track record and customer reviews.

2. Quality and Reliability The quality of a 24x24 centerless grinder is crucial for ensuring consistent production output. Manufacturers who adhere to strict quality control processes and use high-grade materials are generally preferred. It's essential to inquire about warranty and service options as well.

24x24 centerless grinder manufacturers

3. Customization Options Different industries may have specific grinding needs. Some manufacturers offer customizable solutions to cater to unique workpiece specifications. This flexibility can significantly enhance operation efficiency.

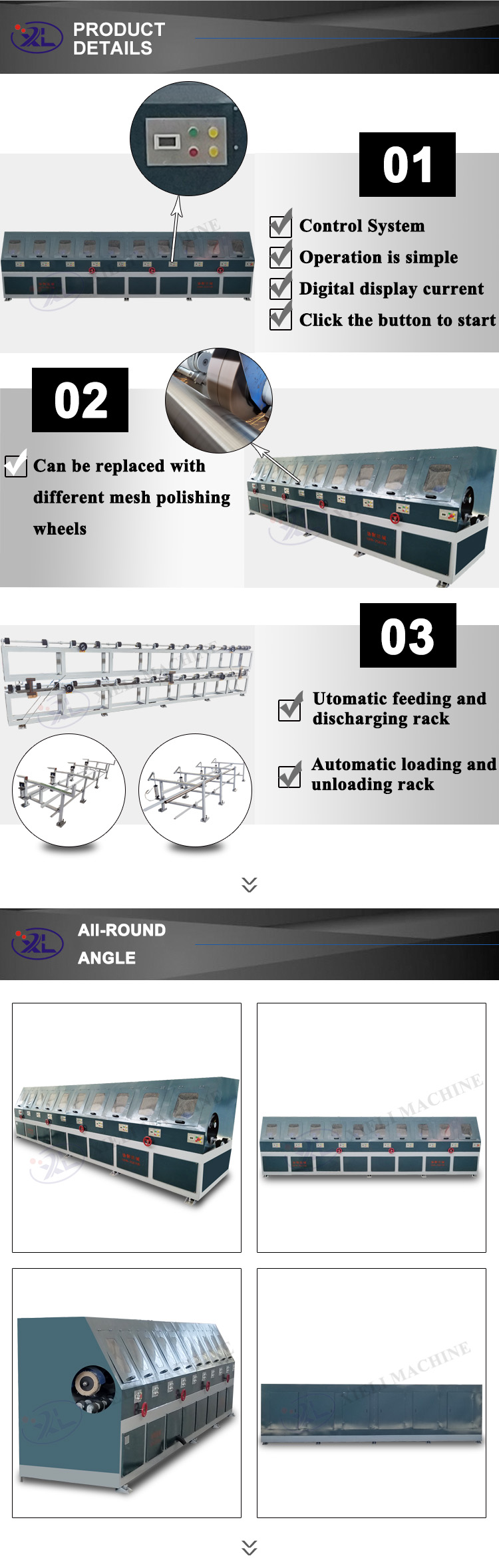

4. Technological Advancements Innovative technologies such as CNC (Computer Numerical Control) integration, automation, and advanced monitoring systems can drastically improve productivity. Manufacturers that invest in these technologies often provide machines with better control and precision.

5. After-Sales Support Reliable after-sales support is vital for maintaining the longevity and performance of a centerless grinder. A manufacturer that offers robust support and regular maintenance services can save businesses time and resources in the long run.

Highlighting Notable Manufacturers

Several manufacturers have garnered recognition in the field of 24x24 centerless grinders. Names like Cincinnati Milacron, Glebar Company, and Koyo Machinery are synonymous with quality and innovation. These companies have developed machines that are not only reliable but also incorporate smart technologies that cater to the evolving demands of manufacturing.

Cincinnati Milacron, for example, has been a key player in the grinder market, offering machines that boast robust construction and user-friendly operation. Their commitment to customer satisfaction is reflected in their comprehensive after-sales services, which ensure that clients get the most out of their equipment.

Glebar Company, on the other hand, has focused on innovation, providing advanced centerless grinding solutions that enhance productivity and precision. Their machines are equipped with state-of-the-art technology, catering to manufacturers that require high levels of accuracy in their processes.

Conclusion

As the manufacturing landscape continues to evolve, the importance of centerless grinders, particularly the 24x24 variety, cannot be overstated. The choice of manufacturer plays a pivotal role in determining the efficiency and effectiveness of production processes. By weighing factors such as reputation, quality, customization, technological advancements, and support, businesses can make informed decisions that lead to successful outcomes. As manufacturers strive to meet the increasing demand for precision and efficiency, the future of centerless grinding looks promising, opening new avenues for industrial innovation and productivity.