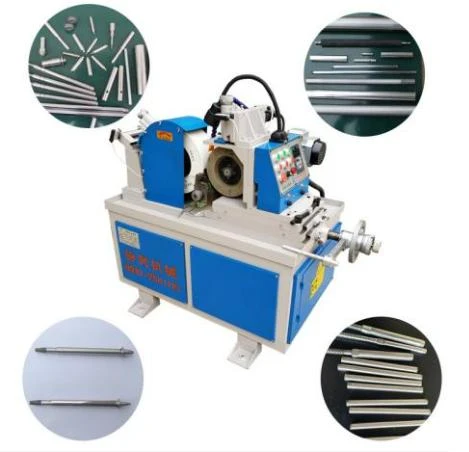

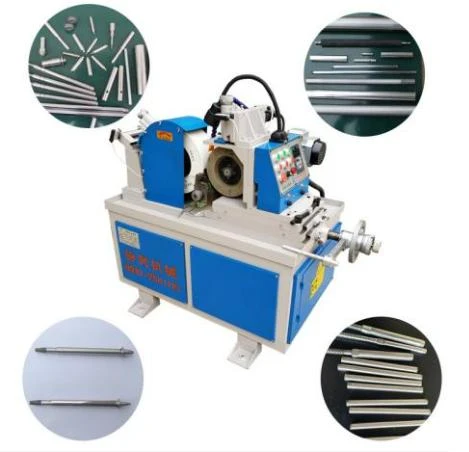

Centerless grinders have emerged as indispensable tools in the realm of precision manufacturing. As a seasoned expert in this technology, I can affirm that their transformative impact on the production of high-quality parts cannot be overstated. These machines are pivotal in industries ranging from automotive to aerospace, primarily due to their ability to produce precise components swiftly and efficiently.

One of the defining features of centerless grinders is their capability to process a diverse range of materials with unparalleled precision. Unlike traditional grinding methods, which require the part to be mounted or clamped, centerless grinders support the workpiece between two rotary wheels, allowing for faster processing and reduced instances of human error. This setup enhances both the speed and accuracy of production, making centerless grinders ideal for mass production environments where consistency is paramount.

In terms of expertise, understanding the nuances of a centerless grinder requires comprehensive knowledge of its unique mechanism. The machine comprises two wheels the grinding wheel which performs the actual grinding work, and the regulating wheel which controls the rotational speed and feed rate of the workpiece. Mastery of the adjustment and synchronization of these wheels is crucial for optimizing machine performance and achieving the desired precision. A professional's ability to effectively manage these variables directly impacts the quality and efficiency of the output.

Authoritativeness in this field involves recognizing the advancements in centerless grinding technology, such as the introduction of automated systems. Modern centerless grinders are often equipped with CNC (Computer Numerical Control) technology, which enhances their precision capabilities even further. Such advancements have broadened the applicability of centerless grinding, enabling more complex geometries and tighter tolerances to be achieved with greater ease.

centerless grinder

Moreover, the reliability of centerless grinders is a testament to their trustworthiness. These machines are renowned for their robust construction and minimal maintenance requirements. When operated correctly, they exhibit impressive longevity, maintaining high levels of accuracy over extensive production runs. This reliability is critical for industries where downtime can result in significant financial losses, underscoring the importance of investing in quality machines and ongoing operator training.

Sharing real-world experience, companies that have integrated centerless grinders into their production lines have reported substantial improvements in both product quality and operational efficiency. For example, in the automotive industry, the need for high-precision components like bearing races and valve lifters is constant. Companies adopting centerless grinding have noted marked improvements in the quality of these parts, often experiencing a reduction in part rejection rates by up to 30%. Such outcomes highlight the tangible benefits of employing centerless grinders.

Altogether, the adoption of centerless grinding technology signifies a strategic investment in manufacturing prowess. For businesses seeking to enhance the precision and efficiency of their production operations, understanding and leveraging the capabilities of centerless grinders can lead to significant competitive advantages. As technologies continue to evolve, the role of the expert becomes even more crucial in ensuring these advancements are fully harnessed. Those who can seamlessly integrate traditional knowledge with cutting-edge innovation will undoubtedly reap the rewards of superior production capabilities.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.