Understanding the Importance of Centerless Finish Grinders in Manufacturing

In the world of manufacturing, the precision and quality of machined components are paramount. Among the various methods employed to achieve impeccable finishes, centerless grinding stands out as a highly effective technique. Centerless finish grinders play a crucial role in streamlining production processes, offering both efficiency and accuracy. In this article, we'll explore the significance of centerless finish grinders, their working principles, applications, and the benefits they provide to manufacturers.

The Basics of Centerless Grinding

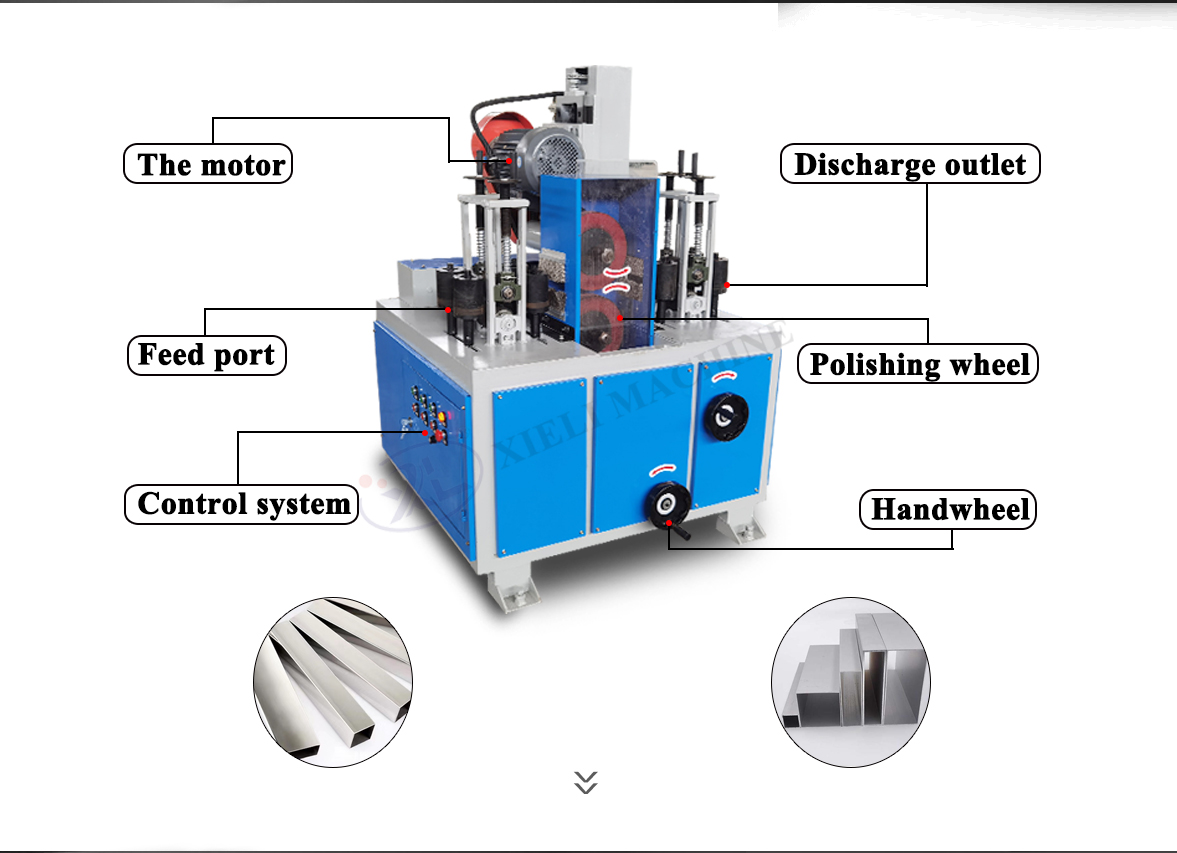

Centerless grinding is a machining process that utilizes the principles of grinding without the need for a spindle or fixture to hold the workpiece. Instead, materials are supported by a regulating wheel that controls the rotational speed and position, while a grinding wheel removes material from the surface. The unique design of the centerless grinder consists of three main components the grinding wheel, the regulating wheel, and the work rest blade.

The workpiece is fed through the grinding wheels, ideally positioned to ensure consistent and accurate material removal. This setup allows for continuous operation, making it an attractive option for high-volume production runs.

Applications of Centerless Finish Grinders

Centerless finish grinders are particularly useful in industries that require high precision and the ability to handle various workpiece shapes and sizes. They are commonly used in the manufacturing of

1. Automotive Components From shafts to bearings, centerless grinders help in achieving the stringent tolerances necessary for automotive parts, ensuring they function efficiently and reliably.

2. Aerospace Components In the aerospace industry, the weight-to-strength ratio of components is crucial. Centerless grinding allows manufacturers to produce lightweight yet durable parts that meet certification standards.

3. Medical Devices The medical industry often requires components that adhere to strict regulatory standards and offer high precision. Centerless grinding ensures that these parts are manufactured to exacting specifications.

buy centerless finish grinder

Advantages of Centerless Finish Grinders

The adoption of centerless finish grinders in manufacturing processes has several advantages

1. High Efficiency Centerless grinders are designed for continuous production, eliminating the need for part loading and unloading after each cycle. This leads to increased throughput and reduced cycle times.

2. Precision Finishes The combination of the regulating wheel and grinding wheel allows for precise control over the diameter and finish of the workpiece, resulting in superior surface integrity.

3. Versatility Centerless grinders can accommodate a wide range of materials and workpiece geometries, making them suitable for various applications, from rods and tubes to intricate profiles.

4. Cost-Effectiveness Although centerless grinding machines can be a significant upfront investment, the long-term benefits, such as reduced labor costs and fewer rejected parts, result in overall savings for manufacturers.

5. Reduced Setup Times Unlike traditional grinding methods that require extensive fixturing, centerless grinders often have quicker setup times, further enhancing productivity.

Conclusion

In conclusion, centerless finish grinders are an indispensable asset in modern manufacturing, contributing significantly to the ability to produce high-quality components efficiently. Their unique operational capabilities allow for versatility across different industries, ensuring that manufacturers can meet their production needs while maintaining high standards of precision and quality.

As technology continues to evolve, the performance of centerless grinders is also expected to advance, incorporating automation and advanced controls to further enhance efficiency. For manufacturers aiming to optimize their production processes and create superior finished products, investing in a centerless finish grinder represents a critical step towards achieving those goals. Understanding their importance will equip businesses to better navigate the complexities of modern manufacturing and stay ahead of the competition.