High-Quality Cincinnati Centerless Grinder Ensuring Precision in Manufacturing

In the realm of manufacturing processes, precision is paramount. Whether it’s in the automotive, aerospace, or general metalworking industries, the need for highly precise and efficient machinery cannot be overstated. Among the formidable tools in the machining arena is the centerless grinder, particularly the high-quality Cincinnati centerless grinders. This equipment not only exemplifies engineering excellence but also plays a critical role in enhancing productivity and maintaining quality standards.

The Importance of Centerless Grinding

Centerless grinding is a method used to shape and machine workpieces without the need for fixtures or complex setups. Unlike traditional grinding techniques, which necessitate the workpiece to be held between centers, centerless grinding allows for continuous operation. This is especially beneficial in mass production environments where consistent dimensions and surface finishes are critical. The design of a centerless grinder helps streamline the process, allowing operators to load workpieces quickly and efficiently.

One of the unique features of centerless grinding is its ability to accommodate various shapes and sizes of workpieces. The setup consists of three main components the grinding wheel, the regulating wheel, and the work rest blade. The workpiece is situated between these elements, allowing for simultaneous grinding on all sides. This makes Cincinnati centerless grinders particularly desirable for parts that require tight tolerances and superior surface finishes.

Cincinnati Centerless Grinders A Legacy of Quality

Cincinnati Machines has a long-standing reputation for manufacturing high-quality centerless grinders that are designed to meet the rigorous demands of the industry. Established in the early 20th century, Cincinnati Machines has evolved its technologies, consistently delivering machines that feature advanced engineering and robust construction.

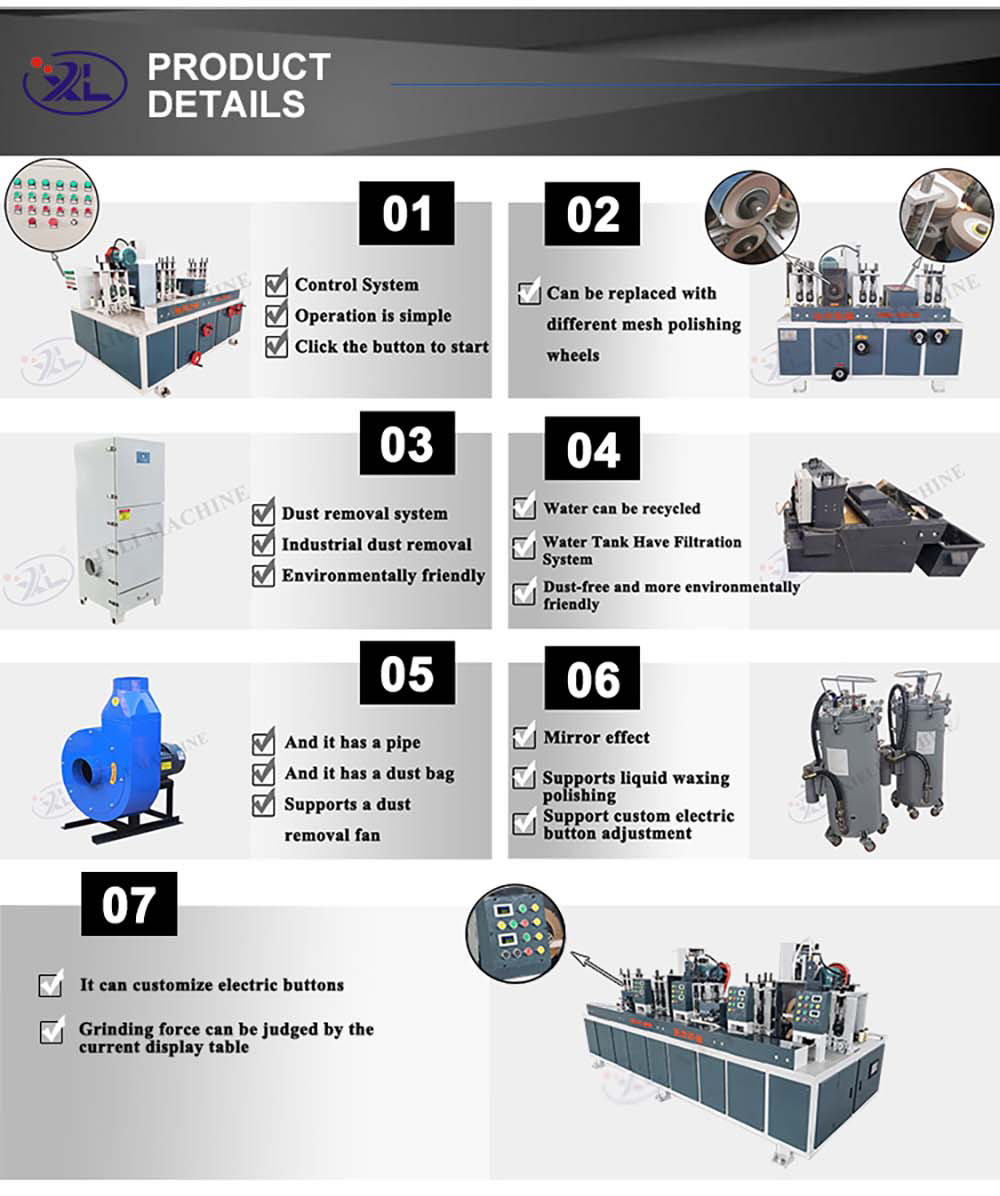

One of the key aspects that set Cincinnati centerless grinders apart is their precision engineering. These machines are equipped with high-speed grinding wheels and superior control systems, ensuring that each workpiece is ground to exact specifications. The ability to fine-tune parameters such as the speed of the grinding wheel and the feed rate allows for a customizable approach to each job, catering to the specific needs of different materials and part geometries.

Advantages of Using High-Quality Cincinnati Centerless Grinders

high quality cincinnati centerless grinder

1. Enhanced Precision Precision is a critical factor that directly impacts the quality of the finished product. Cincinnati centerless grinders are renowned for their accuracy in achieving tight tolerances, which is vital for industries such as aerospace and automotive.

2. Increased Productivity The efficient design of centerless grinders minimizes downtime, allowing for continuous operation. With quick loading and unloading cycles, manufacturers can maximize their output and reduce production costs.

3. Versatility Cincinnati centerless grinders are capable of handling a wide range of workpiece sizes and shapes. This versatility enables manufacturers to adapt to changing market demands and produce various components with the same machine.

4. Durability and Reliability Made from high-quality components, Cincinnati grinders are built to withstand the rigors of manufacturing environments. Their robust construction ensures longevity and reduces the likelihood of unexpected breakdowns.

5. User-Friendly Operation Modern Cincinnati centerless grinders come equipped with intuitive control systems. This makes operation easier for machine operators, reducing the learning curve and enhancing overall productivity.

Conclusion

Investing in a high-quality Cincinnati centerless grinder is an investment in precision, productivity, and quality assurance. As manufacturers continue to strive for excellence in their processes, the importance of reliable and efficient machinery becomes increasingly apparent. The unmatched quality and advanced engineering of Cincinnati centerless grinders position them as a vital tool in meeting the challenges of today’s manufacturing landscape.

In a world where efficiency, accuracy, and cost-effectiveness are essential for success, the Cincinnati centerless grinder stands out as a cornerstone in the manufacturing arsenal, allowing businesses to achieve their goals while maintaining high standards of craftsmanship. Whether you are looking to enhance production capabilities or improve the quality of your outputs, the Cincinnati centerless grinder is a worthy consideration, promising both innovation and excellence in the competitive landscape of machining.