Understanding the intricacies of thru-feed centerless grinding is essential for anyone in the manufacturing industry seeking high precision and efficiency. This high-precision grinding process is widely recognized for its capability to produce smooth surfaces with exceptional accuracy, making it a cornerstone in the production line of various sectors such as automotive, aerospace, and medical equipment manufacturing.

Thru-feed centerless grinding is unique due to its single-pass operation, which makes it extremely efficient for large production runs. Unlike traditional grinding methods that require interrupted feeding and therefore result in downtime, the thru-feed process continuously passes the workpiece through the grinding wheels, yielding a rapid formation of cylindrical parts without the need for additional handling. This aspect is particularly appealing to manufacturers aiming for consistency while upholding a high standard of throughput.

When considering thru-feed centerless grinder manufacturers, it's crucial to evaluate their experience and expertise in the field. An experienced manufacturer not only possesses comprehensive knowledge about the machinery but also a deep understanding of the nuances involved in the grinding process itself. Companies with decades of experience often have developed proprietary technologies and techniques that optimize the grinding process. They are able to offer valuable insights and solutions tailored to specific production needs.

A manufacturer's expertise is also reflected in their ability to innovate and adapt to new materials and industry demands. Leading manufacturers invest heavily in R&D to keep up with technological advancements. They strive to improve the efficiency and versatility of their grinders through features like automation, which reduces human error and further increases productivity. For instance, integrating CNC systems in modern centerless grinders allows for precision control over the grinding process, customizing it to fit varying part sizes and shapes.

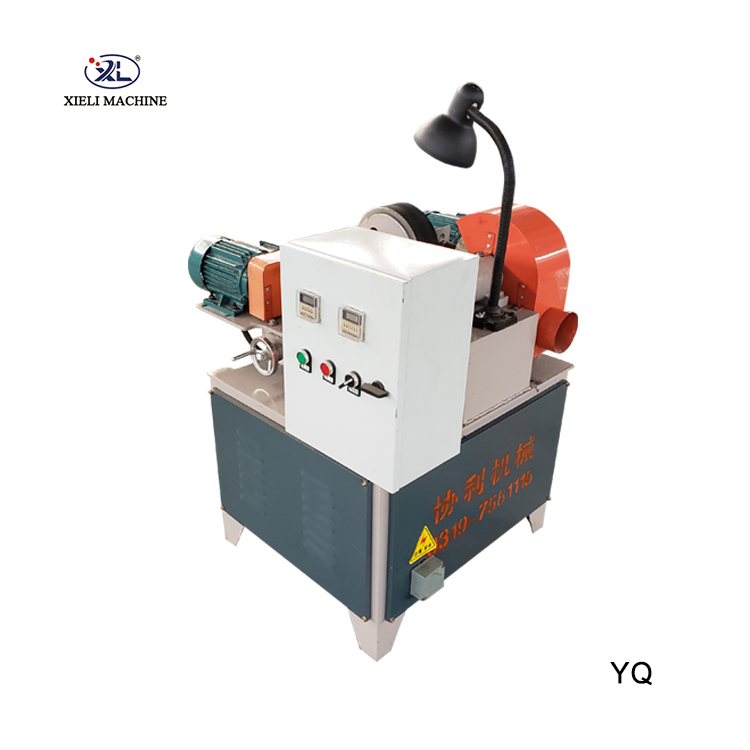

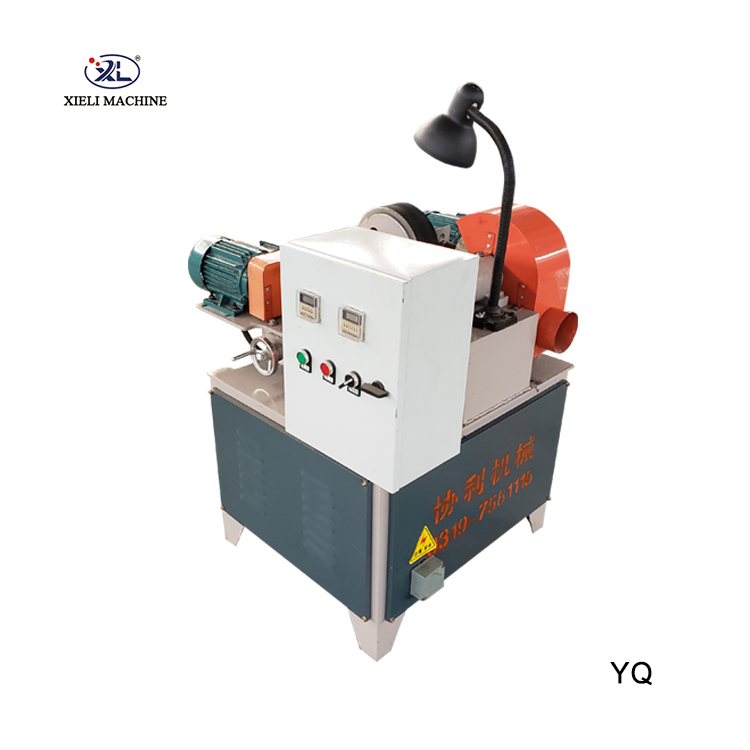

thru feed centerless grinder manufacturers

Authoritativeness in the manufacturing sector comes from not only the company's history and reputation but also its involvement in advancing industry standards. Reputable manufacturers maintain certifications and adhere to international quality standards, demonstrating their commitment to producing reliable and safe equipment. They often contribute to industry publications and forums, sharing knowledge and setting benchmarks for quality and performance. This participation underlines their authoritative voice in shaping grinding technology's future.

Trustworthiness is built upon the manufacturer’s track record of delivering quality products and reliable customer service. Transparent communication, timely support, and comprehensive warranties or service agreements are signs of a trustworthy manufacturer. Enterprises that prioritize client relationships tend to have long-standing partnerships and widespread customer satisfaction, proving their reliability over time.

In conclusion, selecting the right thru-feed centerless grinder manufacturer is pivotal to enhancing production efficiency and product quality. Evaluating potential partners based on experience, expertise, authoritative presence, and trustworthiness will guide you in making an informed decision, securing your production line's success, and maintaining competitive advantage in today’s fast-paced market. Researching thoroughly and choosing a manufacturer who stands out in these areas ensures not just an equipment purchase, but a long-term alliance that supports your operational goals.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.