Exploring Inexpensive Centerless Grinder Factories A Gateway to Cost-Effective Machining Solutions

In the ever-evolving world of manufacturing, precision and efficiency are paramount. Among the essential tools that ensure high-quality machining processes, centerless grinders have emerged as a staple in various industries, particularly in metalworking. As businesses continually seek ways to reduce production costs without compromising quality, inexpensive centerless grinder factories have become key players in the global market.

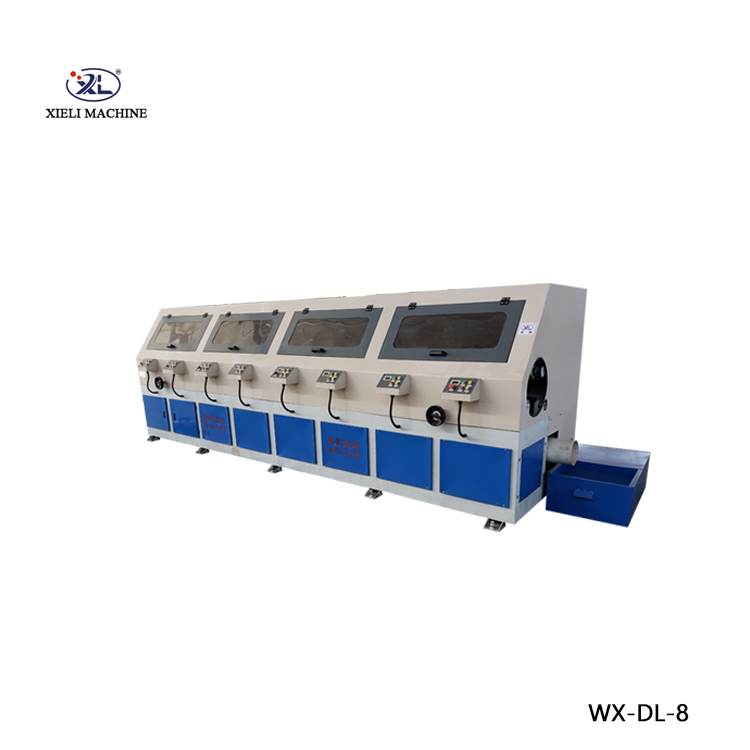

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. The process is particularly beneficial for producing cylindrical parts with tight tolerances. Conventional grinders often require additional setup and handling, whereas centerless grinders allow for continuous production without the need for fixtures or setups. This feature alone has led to increased efficiency and reduced manufacturing costs, making centerless grinders highly sought after.

The rise of inexpensive centerless grinder factories can be attributed to several factors

. First, the global market has become increasingly competitive, pushing manufacturers to lower their prices while maintaining quality. Many factories, particularly in countries with lower production costs, have leveraged advanced manufacturing technologies to produce high-quality grinders at a fraction of the price of their Western counterparts.inexpensive centerless grinder factories

Moreover, the availability of resources and skilled labor in regions like Southeast Asia has further enabled these factories to thrive. Countries such as China, India, and Vietnam have developed robust manufacturing infrastructures, allowing for the mass production of centerless grinders. These factories often utilize modern manufacturing techniques, such as automation and lean production methods, to enhance efficiency and ensure consistent output quality.

Choosing an inexpensive centerless grinder factory can provide significant advantages to businesses. For smaller manufacturers and startups, the cost savings associated with purchasing from these factories can allow for the allocation of funds to other critical areas, such as research and development or expanding production capabilities. Additionally, access to cost-effective machinery can help level the playing field, enabling smaller firms to compete with larger corporations.

However, it is essential to approach the selection of a factory with due diligence. Buyers should prioritize quality assurance processes and certifications to ensure that the machinery meets industry standards. Reliable suppliers often provide detailed information about their manufacturing processes, quality control measures, and after-sales support. Building a good relationship with suppliers can also yield benefits in terms of customization and timely delivery.

In conclusion, inexpensive centerless grinder factories present an exciting opportunity for manufacturers looking to enhance their production capabilities while managing costs. By choosing the right factory, companies can access high-quality machinery that bolsters efficiency and precision in their operations. As the demand for cost-effective machining solutions continues to rise, the importance of these factories in the global manufacturing landscape is set to grow, driving innovation and competitiveness in the industry.