Centerless grinding machines are pivotal in the world of manufacturing, offering an unparalleled edge in achieving precision and efficiency. With years of experience maneuvering through various machining processes, one can attune to the nuances that make centerless grinding indispensable for industries demanding exactitude and high throughput.

Understanding the intricate design of a centerless grinding machine is crucial. These machines operate by resting the workpiece on a support blade while a grinding wheel removes material. Unlike traditional methods, where the workpiece is fixed in place, centerless grinding eliminates the need for workpiece clamps, thus enhancing production speed and accuracy. From my expertise, this operation mechanism allows for an exceptional degree of repeatability and a reduction in downtime.

A compelling testimony that underscores the authority of centerless grinding machines lies in their application across diverse sectors such as automotive, aerospace, and medical device manufacturing. Through extensive trials and consistent performance, centerless grinding has proven its capability in producing components like bearings, bushings, and other cylindrical parts with tight tolerances. For instance, it can efficiently manufacture precision dowels and shafts crucial for engine efficiency and stability, reinforcing its authoritative role in modern manufacturing.

Security and reliability are paramount considerations in machining, and centerless grinding machines deliver on these fronts with formidable reliability. The seamless workflow—a result of the absence of the need to clamp and unclamp the workpiece—translates into a trustworthy process that minimizes human error. Additionally, the gradual wear of the grinding wheel, coupled with in-process dressing mechanisms, ensures that grinding accuracy remains unimpeachable over prolonged production cycles.

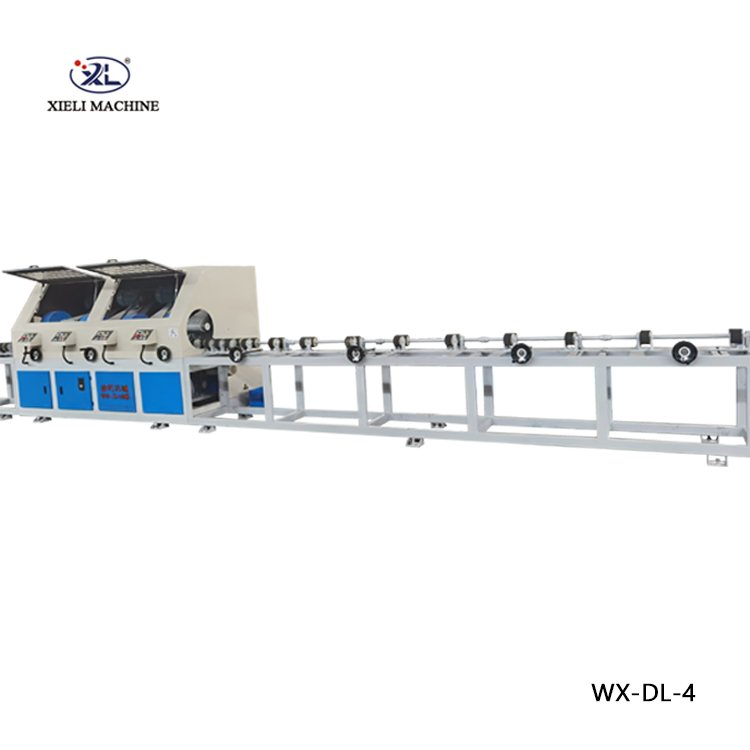

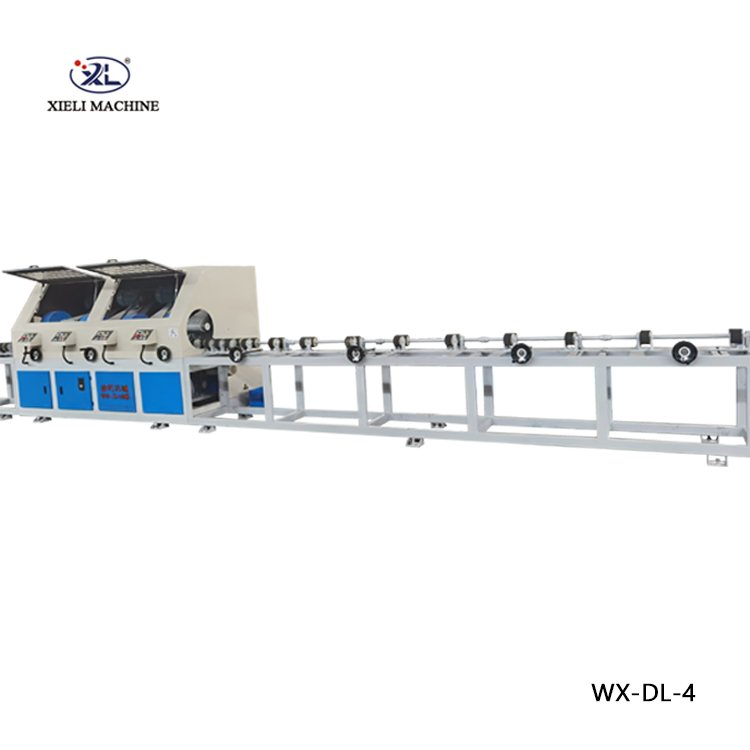

centerless grinding machine

In terms of professional expertise, operators need to master the art of setting the blade height and regulating wheel speed, as these variables critically influence the outcome. Successful mastery of these parameters translates into smoother surface finishes and closer tolerances—often within microns. Through years of practical, hands-on experience, it becomes clear that the nuanced adjustments of these machines demand a blend of skill and intuition, a mark of true expertise.

It's also worth acknowledging centerless grinding's eco-friendliness, underscoring its modern relevance. By optimizing material removal rates and minimizing waste, these machines align well with sustainable manufacturing practices—a trust-building aspect, especially pertinent in environmentally conscious markets.

For businesses intent on scaling their production capabilities without sacrificing precision, the choice of integrating centerless grinding technology is transformative. It remains a cornerstone of efficient and reliable manufacturing strategies, where the balance between expertise and trustworthiness yields a competitive edge. As industries continue to push boundaries, the role of centerless grinding machines as both a linchpin of production and a showcase of mechanical prowess remains undisputed.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.